Water-retaining humic acid controlled-release fertilizer and preparation method thereof

A controlled-release fertilizer and humic acid technology, which is applied in organic fertilizers, fertilizer mixtures, layered/coated fertilizers, etc., can solve problems such as damage, easy slipping of coatings, and short release cycles of slow-release fertilizers, achieving a long release cycle. Adjustment, high gel strength, and the effect of meeting environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

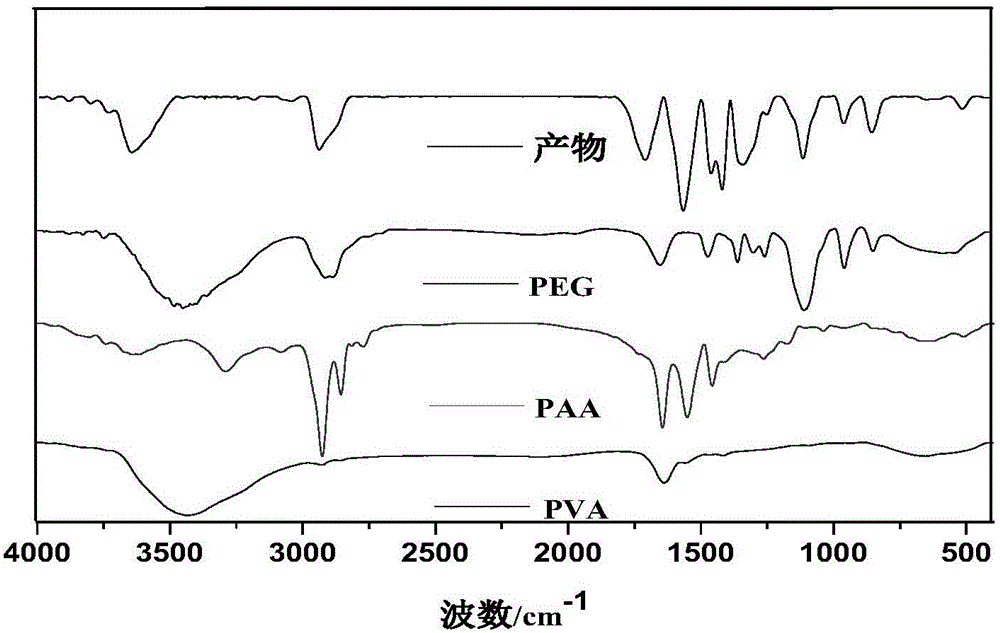

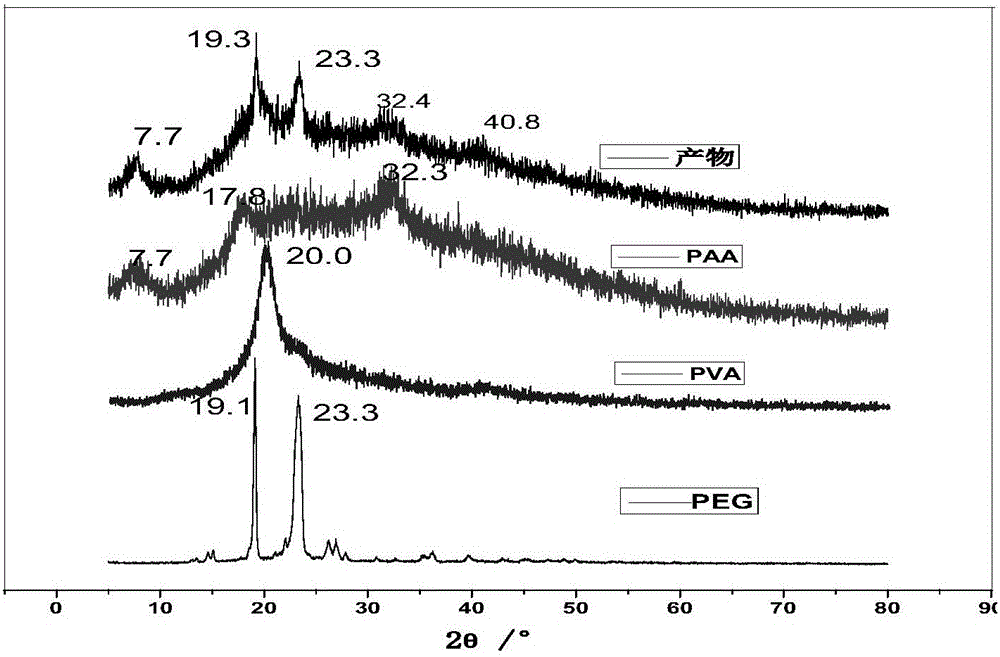

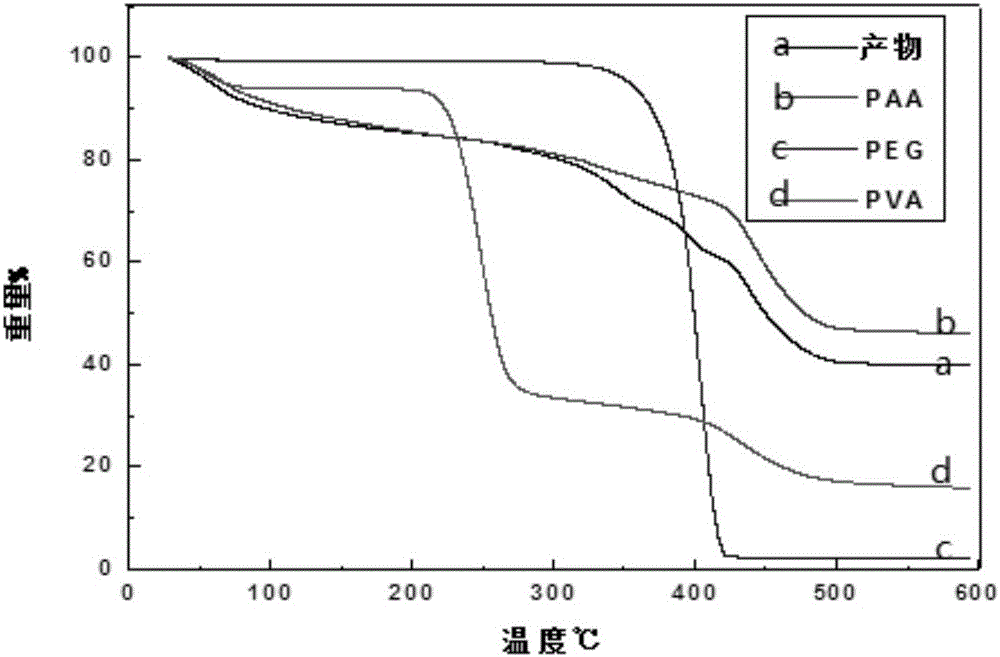

[0029] A method for preparing a water-retaining humic acid controlled-release fertilizer of the present invention. First, PEG, PVA, and AA are used under the action of an initiator and a cross-linking agent to prepare a reaction solution of a composite water-absorbing resin, and the humic acid is mixed before the reaction solution stops stirring. Put the granules into the coating machine, spray the reaction solution for preparing the water-absorbing resin while rotating, stir evenly, heat up, and dry until the water content is not more than 5.0%; you can get PEG / PVA / PAA composite water-absorbing resin-coated humic acid Water-retaining controlled-release granules of acid. Polyethylene glycol: polyvinyl alcohol: initiator: crosslinking agent = 100:10:15:1.1:0.3.

[0030] The reaction solution of the composite water-absorbing resin is made of polyethylene glycol (PEG), acrylic acid (AA) and polyvinyl alcohol (PVA) with a neutralization degree of 70-85% as raw materials, and the n...

Embodiment 1

[0036] Firstly, acrylic acid with a neutralization degree of 75% is miscible with a certain amount of water and placed in a 500ml three-necked flask, and the same amount of initiator in the PEG solution is added to the acrylic acid at 50°C and stirred for 15 minutes. When the temperature was raised to 70°C, the PVA solution and a certain amount of cross-linking agent and initiator mixed solution were added, and reacted at 75°C for 5 hours to obtain a PEG / PVA / PAA reaction solution. Put the humic acid particles with a particle size of 20 mesh into the coating machine, and spray the PEG / PVA / PAA reaction solution at 20 rpm, wherein the humic acid and the reaction solution are mixed evenly at a mass ratio of 100:5; Heating up and drying until the water content is no more than 5.0%; the water-retaining and controlled-release particles of humic acid coated with PEG / PVA / PAA composite water-absorbing resin can be obtained.

Embodiment 2

[0038]Firstly, acrylic acid with a neutralization degree of 75% is miscible with a certain amount of water and placed in a 500ml three-necked flask, and the same amount of initiator in the PEG solution is added to the acrylic acid at 50°C and stirred for 15 minutes. When the temperature is raised to 85°C, the PVA solution and a certain amount of mixed solution of cross-linking agent and initiator are added. React at 75°C for 10 h to obtain a PEG / PVA / PAA reaction solution. Put the humic acid granules with a particle size of 200 mesh into the coating machine, and spray the PEG / PVA / PAA reaction solution at 60 rpm, wherein the humic acid and the reaction solution are mixed evenly at a mass ratio of 100:40; Heating up and drying until the water content is no more than 5.0%; the water-retaining and controlled-release particles of humic acid coated with PEG / PVA / PAA composite water-absorbing resin can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com