A multifunctional vacuum coating machine

A vacuum coating machine and coating machine technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problems of easy breakage of resistance wires, easy control, difficult heat dissipation, etc. Fast heating and good practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

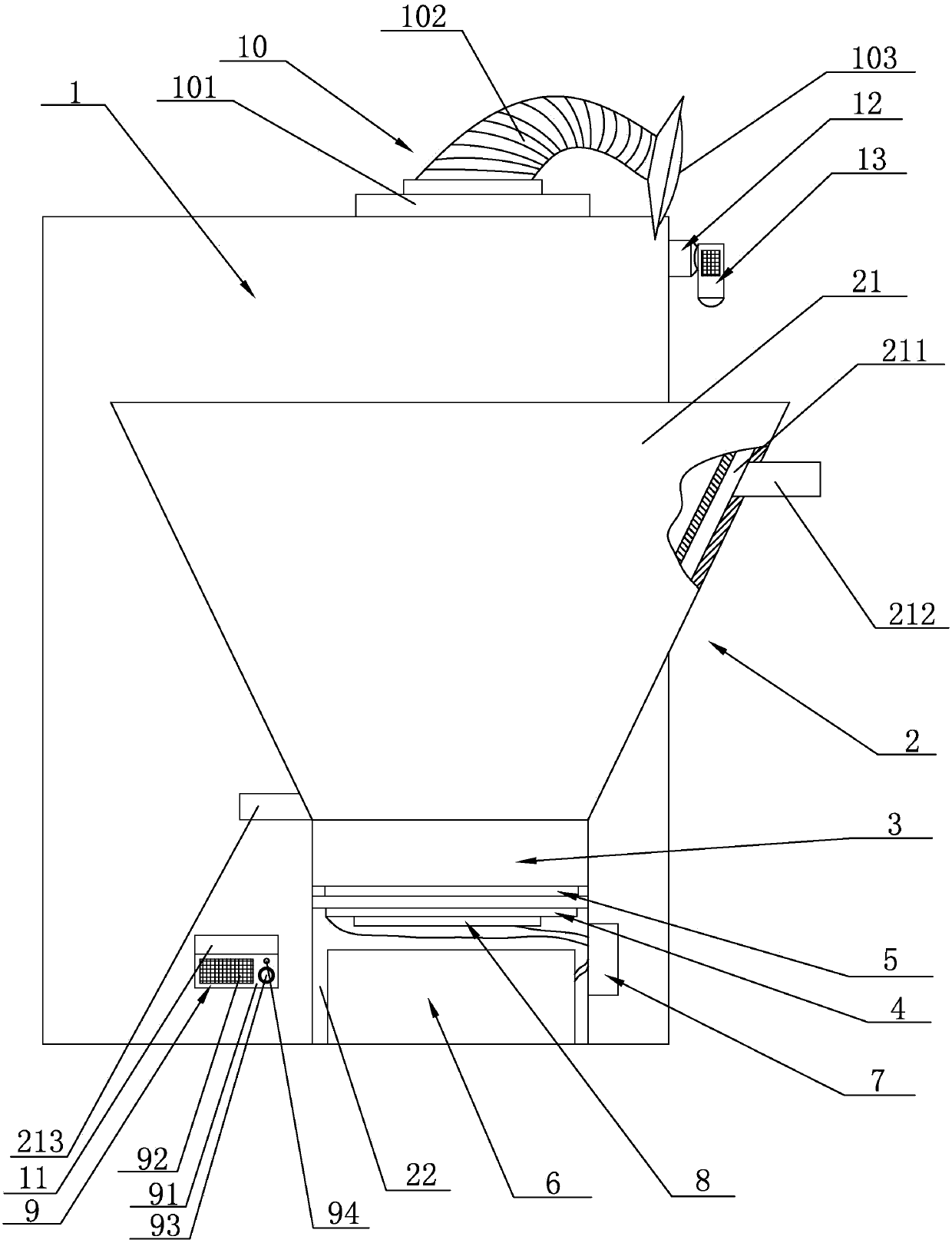

[0017] See figure 1 , The present invention discloses a multifunctional vacuum coating machine, comprising a coating machine body 1, a diffusion pump 2 is provided on one side of the coating machine body 1, and the diffusion pump 2 includes a diffusion pump body 21 and an integrated diffusion pump body 21 The diffusion pump base 22 is provided with a heat preservation cavity 211 in the wall surface of the diffusion pump body 21, and the upper end of the diffusion pump body 21 is provided with a water filling port 212 communicating with the heat preservation cavity 211, and the lower end of the diffusion pump body 21 is provided with The water outlet 213 connected with the heat preservation cavity 211; the diffusion pump base 22 is fixedly provided with a coating machine chassis 3, the coating machine chassis 3 is filled with diffusion pump oil, and the bottom of the coating machine chassis 3 is provided with an inductance coil 4 A layer of heat preservation layer 5 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com