Pretreatment method for various organic pollutants in solid medium

A technology of organic pollutants and medium, which is applied in the field of pretreatment of organic pollutants to achieve the effects of saving time, high comparability and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

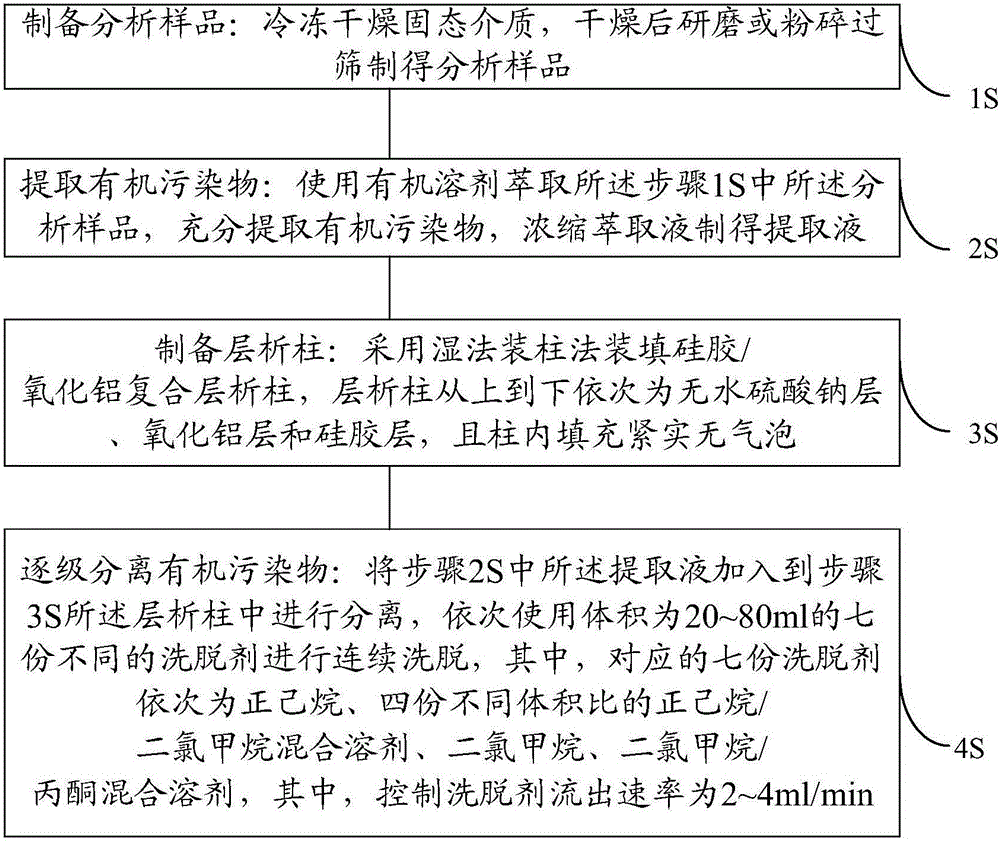

Method used

Image

Examples

Embodiment 1

[0045] After the soil is fully ground, take 3g and extract it with an accelerated solvent extraction machine to obtain a blank soil. Add 1ml of a standard sample to the soil after the organic matter has been extracted. The standard sample contains PCBs (100ppb), PAHs (100ppb), DDT (100ppb) , wax esters (100ppb), alkylphenols (100ppb), NPEO (100ppb), phthalates (100ppb), estradiol (100ppb) and other components. After fully mixing, put it into the refrigerator as a simulated analysis sample, and perform the following treatments on the simulated analysis sample:

[0046] 1S preparation of analysis samples: thaw the frozen simulated soil sample at room temperature, then freeze-dry on a freeze dryer, grind or pulverize the dried sample, and pass through a 240-mesh stainless steel sieve;

[0047] 2S extraction of organic pollutants: wash the extraction pool of the accelerated solvent instrument (ASE 300, Dionex U.S.A) with n-hexane, dichloromethane, and methanol three times respecti...

Embodiment 2

[0052] After the sediment (bottom mud) is fully ground, take 2g and extract it with an accelerated solvent extraction machine to obtain a blank bottom mud. Add 1ml of a standard sample to the bottom mud after the organic matter has been extracted. This standard sample contains PCBs (100ppb), DDE ( 100ppb), PAHs (100ppb), DDD (100ppb), wax esters (100ppb), alkylphenols (100ppb), NPEO (100ppb), phthalates (100ppb), bisphenol A (100ppb) and other groups point. After fully mixing, put it into the refrigerator as a simulated analysis sample, and carry out the treatment similar to that in Example 1 to the simulated analysis sample.

[0053] Step 1S and Step 2S adopt the processing method in Embodiment 1.

[0054] 3S Preparation of Chromatographic Column: The silica gel / alumina composite chromatographic column is packed by wet packing method. The inner diameter of the chromatographic column is 10mm. The chromatographic column is anhydrous sodium sulfate layer, alumina layer and sili...

Embodiment 3

[0058] After the soil is fully ground, take 3g and extract it with an accelerated solvent extraction machine to obtain a blank bottom mud. Add 1ml of a standard sample to the bottom mud after the organic matter has been extracted. The standard sample contains PCBs (100ppb), DDE (100ppb), PAHs ( 100ppb), DDT (100ppb), DDD (100ppb), wax esters (100ppb), alkylphenols (100ppb), NPEO (100ppb), phthalates (100ppb), bisphenol A (100ppb), estrogen Phenol ketone (100ppb) and other components. After fully mixing, put it into the refrigerator as a simulated analysis sample, and carry out the treatment similar to that in Example 1 to the simulated analysis sample.

[0059] Step 1S and Step 2S adopt the processing method in Embodiment 1.

[0060] 3S Preparation of Chromatographic Column: The silica gel / alumina composite chromatography column is packed by wet packing method. The inner diameter of the chromatography column is 16mm. The chromatography column is composed of anhydrous sodium s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com