A kind of carbon fiber composite cable with optical fiber and preparation method thereof

A carbon fiber and composite cable technology, applied in the direction of fiber mechanical structure, optics, light guide, etc., can solve problems such as structural instability, interface material mismatch, optical fiber damage, etc., to improve impact resistance and bending characteristics, and improve overall stability , to ensure the effect of concentric positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

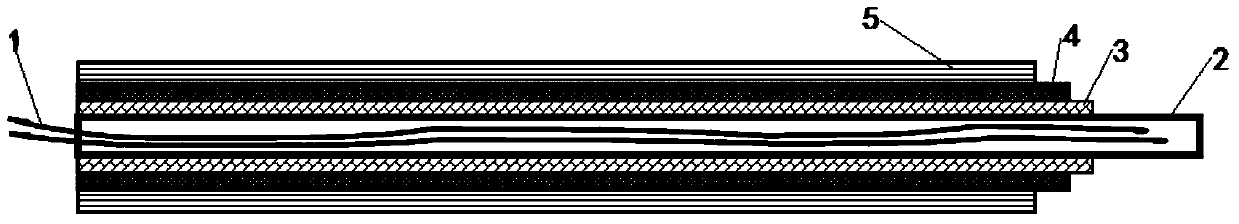

[0037] A carbon fiber composite cable with optical fiber, including four preparation processes from the core to the outermost surface: surface treatment of metal sleeve with optical fiber, preparation of interface layer of carbon fiber braided sleeve reinforced thermoplastic resin composite material, carbon fiber The anti-seismic layer of the braided sleeve reinforced thermoplastic thermosetting composite resin is prepared, and the carbon fiber unidirectional composite conductor layer is prepared on the outermost surface.

[0038]First, embed two single-mode optical fiber filaments in a continuous-length metal sleeve with a diameter of 1 mm. The surface of the metal sleeve is immersed in an aqueous solution of concentrated sulfuric acid / potassium dichromate at 60-65°C for 10-30 minutes, and then taken out with water. Rinse and line dry or tumble dry below 80°C.

[0039] Second, weave 3K 12 strands of T300 high-strength carbon fiber on the outside of the surface-treated metal s...

Embodiment 2

[0046] A carbon fiber composite cable with optical fiber, including four preparation processes from the core to the outermost surface: surface treatment of metal sleeve with optical fiber, preparation of interface layer of carbon fiber braided sleeve reinforced thermoplastic resin composite material, carbon fiber The preparation of the anti-seismic layer of the braided sleeve reinforced thermoplastic thermosetting composite resin, and the preparation of the carbon fiber unidirectional composite wire layer on the outermost surface.

[0047] First, embed three multimode optical fiber filaments in a continuous-length metal sleeve with a diameter of 3mm. The surface of the metal sleeve is dipped in a mixture of phosphoric acid / chromium oxide / alcohol / formaldehyde at 15-30°C for 10-15min. Then wash and dry at 60-80°C.

[0048] Second, weave 6K 16 strands of T700 high-strength carbon fiber on the outside of the surface-treated metal sleeve with optical fiber. The carbon fiber is impr...

Embodiment 3

[0055] A carbon fiber composite cable with optical fiber, including four preparation processes from the core to the outermost surface: surface treatment of metal sleeve with optical fiber, preparation of interface layer of carbon fiber braided sleeve reinforced thermoplastic resin composite material, carbon fiber The preparation of the anti-seismic layer of the braided sleeve reinforced thermoplastic thermosetting composite resin, and the preparation of the carbon fiber unidirectional composite wire layer on the outermost surface.

[0056] First, embed four polarization-maintaining optical fiber filaments in a continuous-length metal sleeve with a diameter of 2mm. The surface of the metal sleeve is made of concentrated sulfuric acid 22g / l, and the 2 Immerse for 10-15min under direct current strength, then soak in saturated potassium dichromate solution for 5-20min at 95-100°C, then wash with water and dry.

[0057] Second, weave 12K 10 strands of T800 high-strength carbon fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com