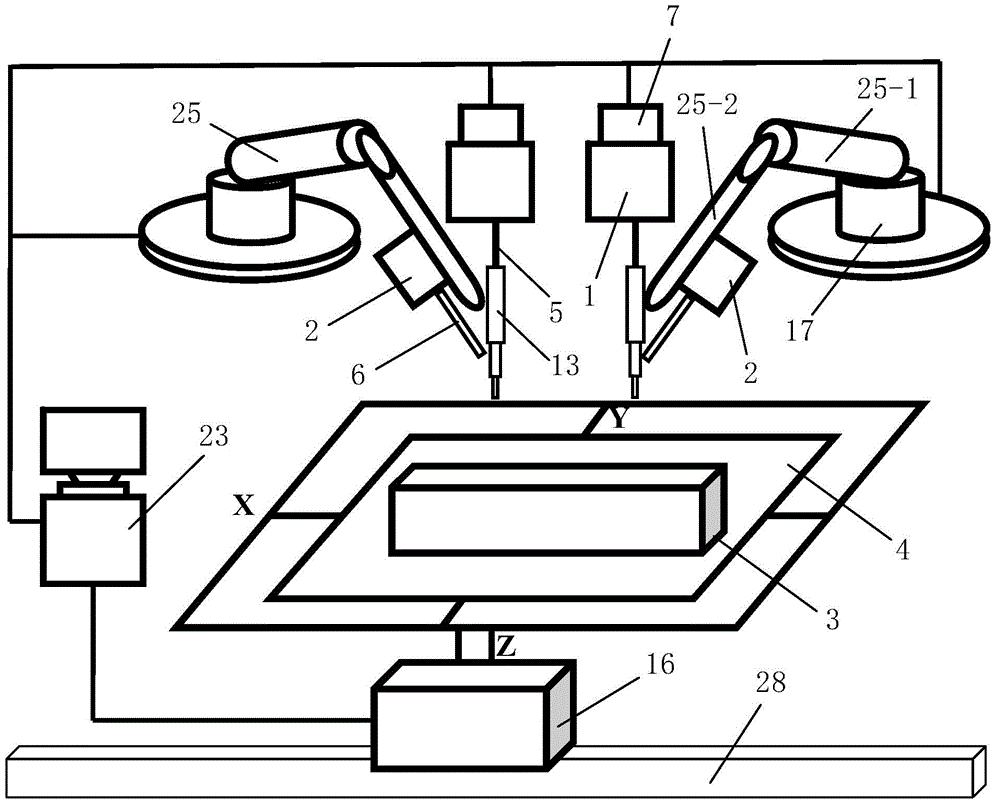

Plasma fusion covering direct manufacture 3D printing equipment and method

A technology of plasma cladding and 3D printing, applied in manufacturing tools, ceramic molding machines, improving energy efficiency, etc., which can solve problems such as high maintenance costs, high operating costs, and uneven surface of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

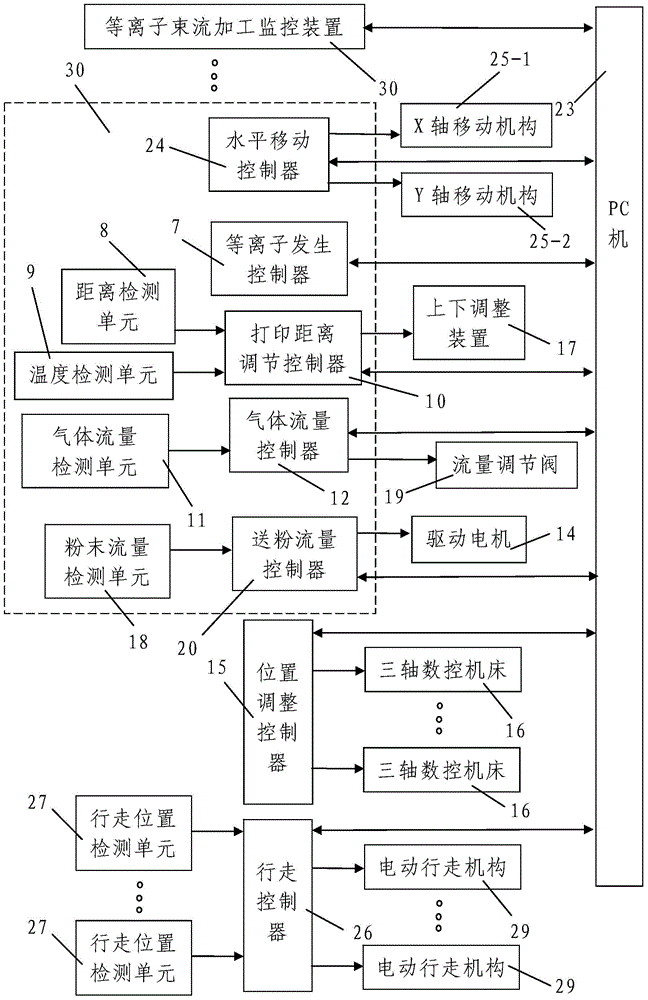

Method used

Image

Examples

Embodiment 2

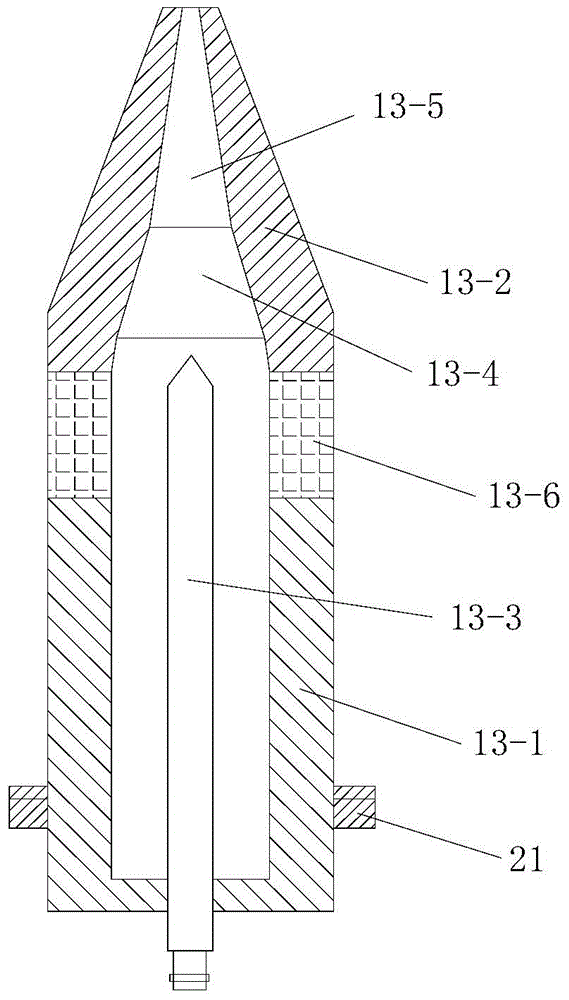

[0200] In this embodiment, such as Figure 7 As shown, the plasma cladding direct manufacturing 3D printing equipment used is different from Embodiment 1 in that the angle between the nozzle 13-5 and the central axis of the gun body 13-1 is 30°-45°.

[0201] In this way, after the direction of the plasma beam is changed through the nozzle 13-5, the thermal load impact of the plasma jet on the anode nozzle 13-2 can be effectively reduced, and the anode ablation condition is improved.

[0202] In this embodiment, the structure, connection relationship, and working principle of the rest of the 3D printing device directly manufactured by plasma cladding are the same as those in Embodiment 1.

[0203] In this embodiment, the plasma cladding direct manufacturing 3D printing method used is the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com