Device and method for quickly recovering deuterium and tritium in fusion reactor discharged ash gases

A recovery device and fusion reactor technology, applied in the field of fusion reactors, can solve problems such as the adverse effects on the service life of Pd alloy membrane separators and system stability, the processing speed of CAPER process and insufficient tritium retention in the system, and the reduction of impurity gas content, etc. To avoid adverse effects, reduce tritium retention, and reduce the amount of impurity gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

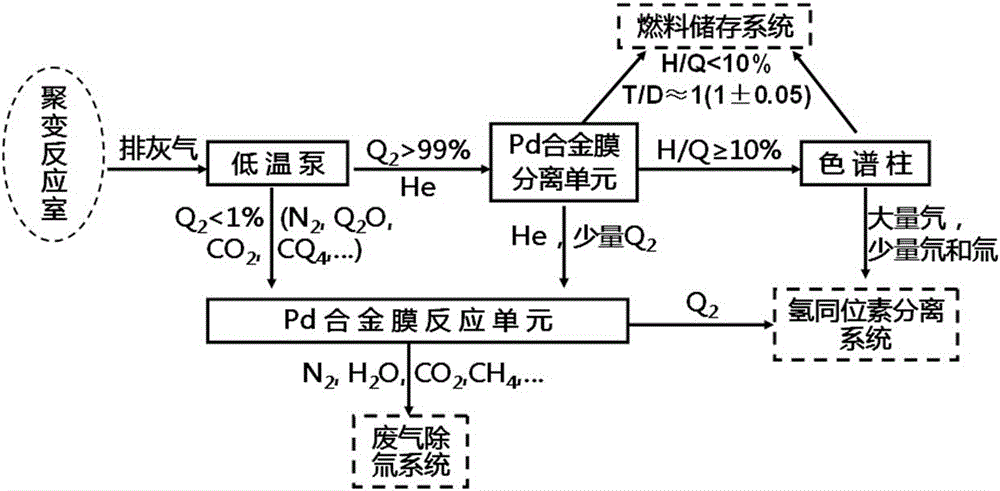

[0048] The composition and content of the ash gas are as follows: Q 2 99.10%, He 0.50%, Q 2 O 0.10%, CQ 4 0.08%, CO 0.06%, CO 2 0.03%, N 2 0.10%, O 2 0.03%.

[0049] In this example, since the impurity gas content is very low (less than 1.0%), it has little effect on the performance of the Pd alloy film, and the front and rear stages of the cryopump desorb simultaneously to obtain gas , directly into the Pd alloy membrane separation unit, the permeate gas of the Pd alloy membrane separation unit is high-purity (>99.999%) Q 2 (denoted as gas ),gas The contents of protium, deuterium and tritium (volume percentage) are 2.0%, 48.7% and 49.3% respectively, which directly enter the tritium storage system. The tail gas separated by the Pd alloy membrane separation unit (denoted as tail gas ) contains a small amount of Q 2 and He, Q 2 O, CQ 4 , CO, CO 2 , N 2 , O 2 and other impurity gases are stored in the buffer device (in this embodiment, the buffer device ad...

Embodiment 2

[0052] In the present embodiment, the component and content of ash exhaust gas are as follows: Q 2 94.10%, He 2.80%, Q 2 O 0.80%, CQ 4 0.65%, CO 0.35%, CO 2 0.28%, N 2 0.90%, O 2 0.12%.

[0053] In this example, due to the relatively high content of impurity gases, the front and rear stages of the cryopump were desorbed separately, and the low-temperature molecular sieve column in the front stage was desorbed at room temperature to obtain tail gas , the subsequent helium-refrigerated cryopump desorbs the gas at 77K . gas The main component is Q 2 and He, exhaust Contains a small amount of Q 2 and He, Q 2 O, CQ 4 , CO, CO 2 , N 2 , O 2 and other impurity gases. gas Enter the Pd alloy membrane separation unit to get the gas and exhaust ,gas The contents of protium, deuterium and tritium are 11.0%, 44.2% and 44.8% respectively. due to gas The content of protium in the medium is relatively high, and it enters the filling of Al 2 o 3 +1%SiO2 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com