Dichlorobenzidine polluted sludge treating agent and preparation method thereof

A dichlorobenzidine and sludge treatment technology, which is applied in sludge treatment, water/sludge/sewage treatment, water pollutants, etc., can solve problems such as soil ecological environment hazards, achieve good treatment effect, stable performance, High recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

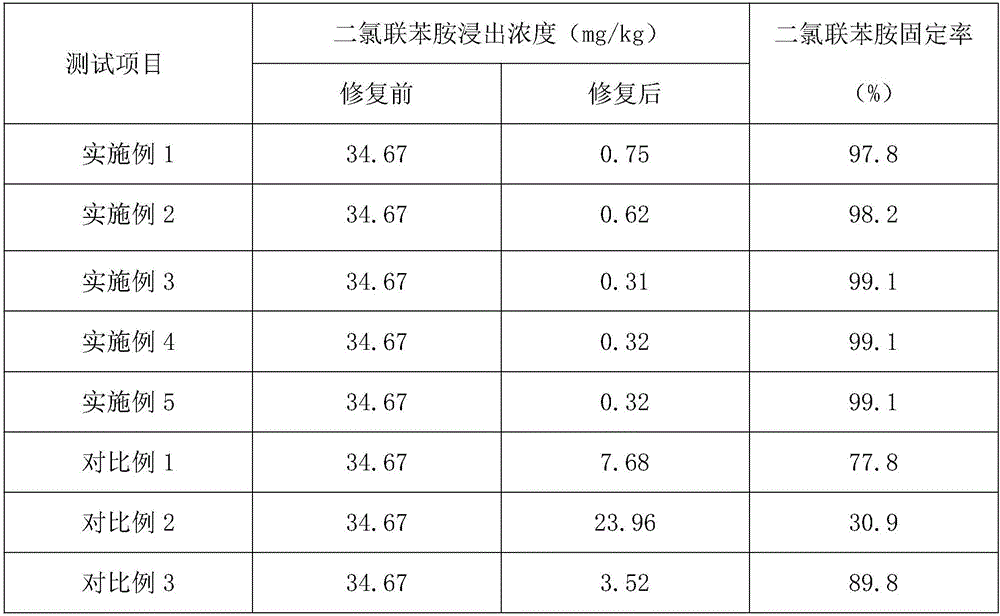

Examples

Embodiment 1

[0020] A dichlorobenzidine contaminated sludge treatment agent, the main raw materials in parts by weight are: 20 parts of nano-modified sludge, 10 parts of bamboo charcoal, 15 parts of vinyltriethoxysilane, 10 parts of polyacrylamide, diisocyanate 10 parts, 3 parts of beeswax, 0.2 part of trishydroxymethylaminomethane, 0.2 part of apatite; the preparation method of the nano-modified sludge: first vegetable oil, glacial acetic acid, 5-aminolevulinic acid are mixed and carried out The mixture is obtained by vacuum filtration, and then the borax, the sludge and the mixture are reacted under microwave to obtain the nano-modified sludge; the particle size of the bamboo charcoal is 600 μm; the mesh number of the tris is 800 head.

[0021] The preparation method of described dichlorobenzidine polluted sludge treatment agent, concrete steps are:

[0022] (1) First, put bamboo charcoal and vinyltriethoxysilane into the nano-modified sludge, process it in a twin-shaft agitator for 30 ...

Embodiment 2

[0027] A dichlorobenzidine contaminated sludge treatment agent, the main raw materials in parts by weight are: 22 parts of nano-modified sludge, 12 parts of bamboo charcoal, 17 parts of vinyltriethoxysilane, 13 parts of polyacrylamide, diisocyanate 10 parts, 3 parts of beeswax, 0.2 part of trishydroxymethylaminomethane, 0.2 part of apatite; the preparation method of the nano-modified sludge: first vegetable oil, glacial acetic acid, 5-aminolevulinic acid are mixed and carried out The mixture is obtained by vacuum filtration, and then the borax, the sludge and the mixture are reacted under microwave to obtain the nano-modified sludge; the particle size of the bamboo charcoal is 600 μm; the mesh number of the tris is 800 head.

[0028] The preparation method of described dichlorobenzidine polluted sludge treatment agent, concrete steps are:

[0029] (1) First, put bamboo charcoal and vinyltriethoxysilane into the nano-modified sludge, process it in a twin-shaft agitator for 30 ...

Embodiment 3

[0034] A dichlorobenzidine contaminated sludge treatment agent, the main raw materials in parts by weight are: 25 parts of nano-modified sludge, 15 parts of bamboo charcoal, 20 parts of vinyltriethoxysilane, 14 parts of polyacrylamide, diisocyanate 13 parts, 4 parts of beeswax, 0.3 part of trishydroxymethylaminomethane, 0.3 part of apatite; the preparation method of the nano-modified sludge: first vegetable oil, glacial acetic acid, 5-aminolevulinic acid are mixed and carried out The mixture is obtained by vacuum filtration, and then the borax, the sludge and the mixture are reacted under microwave to obtain the nano-modified sludge; the particle size of the bamboo charcoal is 600 μm; the mesh number of the tris is 800 head.

[0035] The preparation method of described dichlorobenzidine polluted sludge treatment agent, concrete steps are:

[0036] (1) First, put bamboo charcoal and vinyltriethoxysilane into the nano-modified sludge, process it in a twin-shaft agitator for 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com