A sterile dispensing system

A dispensing system and dispensing technology, applied in medical containers, drug packaging, packaged food, etc., can solve the problems of increased drug contamination, high labor intensity, and difficult operation, so as to avoid medical accidents, reduce labor intensity, and protect the environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Different from the aseptic dispensing system described above, this embodiment is different in that one end of the front push rod 41 is provided with an external thread, and the tail end of the rubber plug 2 is provided with a The internal thread joint corresponding to the external thread; through the front push rod 41 rotating around the axis while advancing, the external thread of the front push rod 41 is screwed with the internal thread joint of the rubber plug 2, so that the The front push rod 41 is combined with the rubber plug 2 .

Embodiment 2

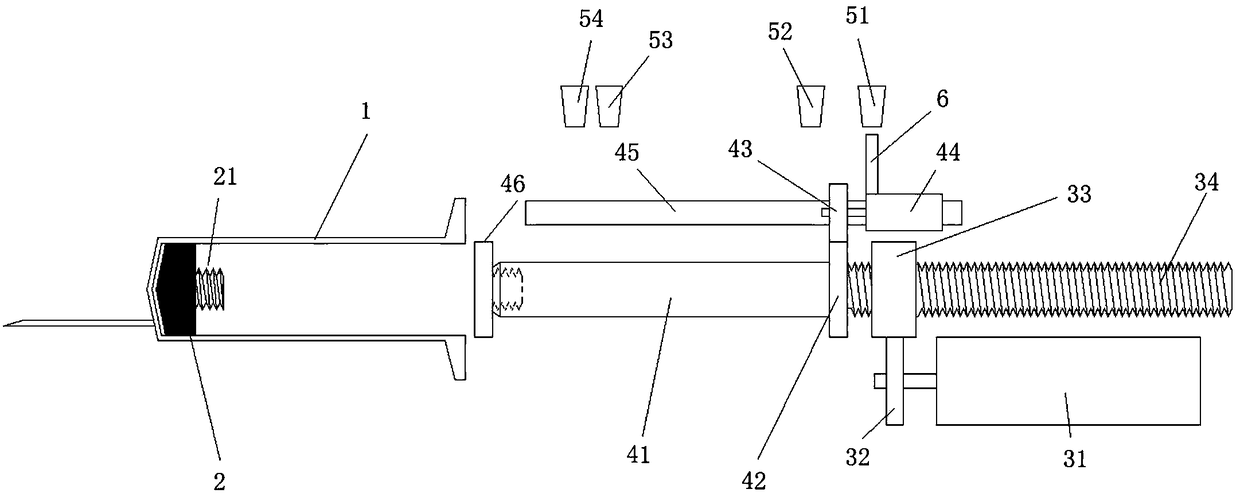

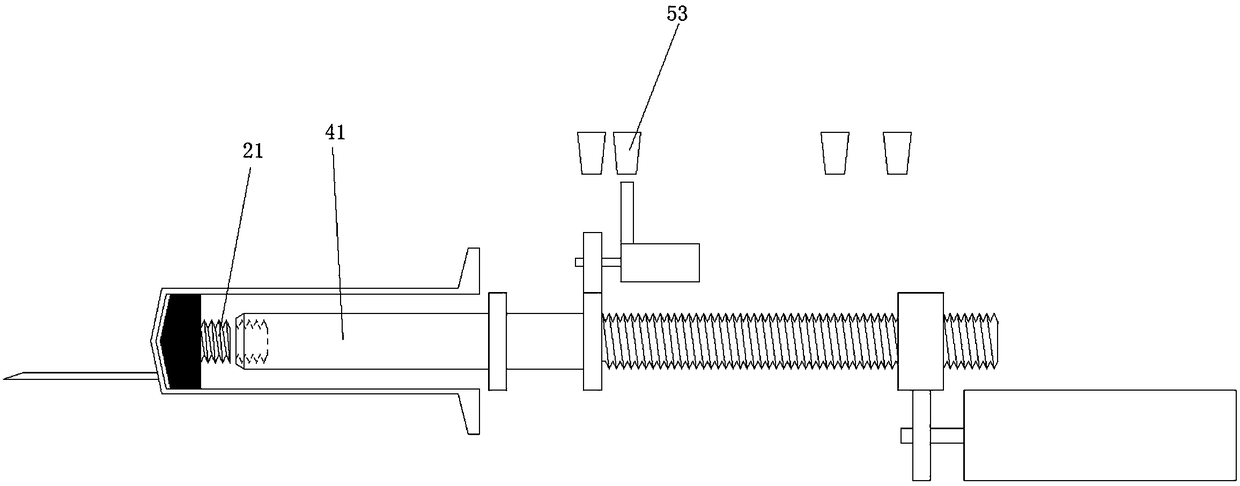

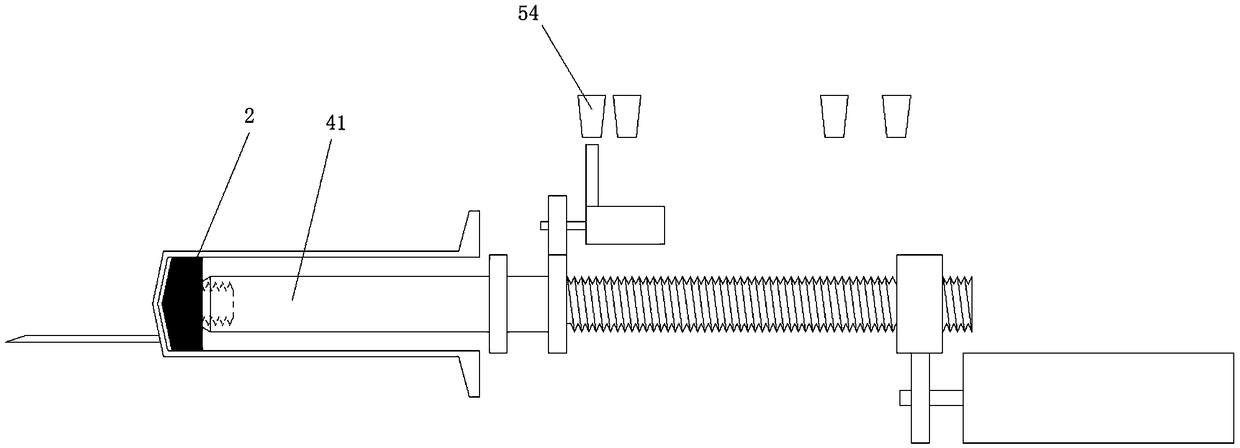

[0049] Different from the above-mentioned aseptic dispensing system, the difference of this embodiment is that the aseptic dispensing system is also provided with a plurality of photoelectric position sensors and a photoelectric shutter that can move with the joint 6. Through the cooperation of the photoelectric position sensor and the photoelectric shutter 6, the on-off of the circuit can be realized to control the rotation of the push rod motor 31 and the rod head rotation motor 44; figure 1 As shown, when the photoelectric barrier 6 senses the first photoelectric position sensor 51, the front push rod 41 is at the farthest position from the syringe barrel 1, and the front push rod 41 does not extend into Inside the syringe barrel 1, at this time, the rubber plug 2 is located at the front end of the syringe barrel 1; figure 2 As shown, the front push rod 41 gradually extends into the interior of the syringe barrel 1 under the drive of the actuating part. When the photoelect...

Embodiment 3

[0051] Different from the aseptic dispensing system described above, the difference in this embodiment is that the front push rod 41 is placed in an aseptic structure, and the syringe barrel 1 is in a sealed connection with the joint. Therefore, when the front push rod 41 is pushed into the syringe barrel 1, it is in a sterile environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com