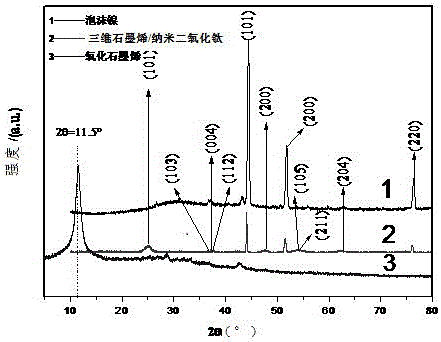

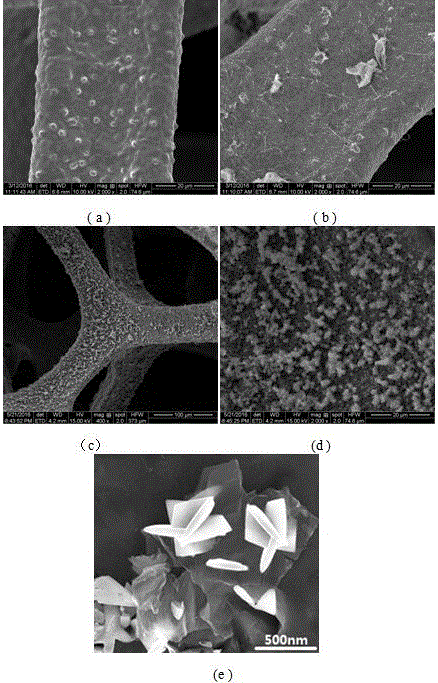

Three-dimensional graphene and nanometer titania composite photocatalyst and preparation method thereof

A nano-titanium dioxide and graphene technology, applied in the field of nanomaterials and photocatalysis, can solve the problems of uncontrollable morphology, weak interaction, cumbersome process flow, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Clean the nickel foam of 10mm*10mm*1mm with dilute hydrochloric acid, acetone and absolute ethanol in sequence, then wash it with deionized water and dry it.

[0026] (2) Put 10 mg of graphene oxide prepared by the Hummers method in a beaker filled with distilled water, and sonicate in an ultrasonic instrument to obtain a concentration of 5 mg·ml -1 graphene oxide aqueous solution.

[0027] (3) Soak the nickel foam treated in step (1) directly into a 20ml graphene oxide aqueous solution beaker, and then sonicate and soak to finally form a three-dimensional graphene oxide material. During the ultrasonic immersion process, the reaction temperature is 40°C, the frequency is 40KHz, ultrasonic is used for 20 minutes, the interval is 5 minutes, and the ultrasonic immersion is performed for another 20 minutes. The total ultrasonic immersion time is 2 hours.

[0028] (4) Dry the prepared three-dimensional graphene oxide material, and then raise the temperature to 480°C in ...

Embodiment 2

[0031] (1) Clean the nickel foam of 10mm*10mm*1mm with dilute hydrochloric acid, acetone and absolute ethanol for 12 minutes, then wash it with deionized water for 5 minutes and then dry it.

[0032] (2) Put 10 mg of graphene oxide in a beaker filled with distilled water and sonicate in an ultrasonic instrument for 2 hours to obtain a concentration of 3 mg·ml -1 graphene oxide aqueous solution.

[0033] (3) Soak the nickel foam treated in step (1) directly into a 20ml graphene oxide aqueous solution beaker, and then sonicate and soak to finally form a three-dimensional graphene oxide material. During the ultrasonic immersion process, the reaction temperature was 70°C, the frequency was 40KHz, ultrasonic was used for 20 minutes, and the interval was 5 minutes, followed by ultrasonic immersion for another 20 minutes. The total ultrasonic immersion time was 3 hours.

[0034] (4) Dry the prepared three-dimensional graphene oxide material, and then raise the temperature to 450°C i...

Embodiment 3

[0037] (1) Put 10 mg of graphene oxide in a beaker filled with distilled water and sonicate in an ultrasonic instrument to obtain a concentration of 6 mg·ml -1 graphene oxide aqueous solution.

[0038] (2) Soak 10mm*10mm*1mm nickel foam directly into a 20ml graphene oxide aqueous solution beaker, and then ultrasonically soak to form a three-dimensional graphene oxide material. During the ultrasonic immersion process, the reaction temperature was controlled at 80°C, the frequency was 40KHz, the ultrasound was performed for 20 minutes, and the interval was 5 minutes, followed by another 20 minutes of ultrasound. The total ultrasonic immersion time was 1 hour.

[0039] (3) Dry the prepared three-dimensional graphene oxide material, and then raise the temperature to 500°C at a rate of 4°C / min under vacuum in a tube furnace, and take it out after holding for 2 hours.

[0040] (4) Dissolve 0.50ml of HCl and 0.4ml of titanium tetrachloride in 30ml of absolute ethanol in turn, and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com