Surface treatment process of natural soft wooden plug

A treatment process and cork technology, applied in wood treatment, wood treatment details, and devices for coating liquid on the surface, etc., can solve the problems of high wine leakage rate of leached pigments, achieve reduced wine leakage rate, strong barrier performance, and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

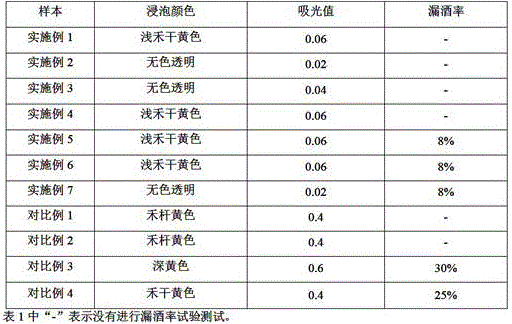

Examples

Embodiment 1

[0026] Put 10,000 extra-grade natural corks into the drum, and heat while rolling, so that the corks are evenly heated and preheated to a surface temperature of 30°C; spray 5L on the surface of the preheated corks with a mass percentage concentration of 14 % of acrylic resin aqueous solution, the spraying rate is 1.0L / min, and the spraying pressure is 0.3MPa; the roller is rolled to make the acrylic resin aqueous solution evenly rolled on the cork, and heated until the surface temperature of the cork is 60°C , keep the drum rolling, and keep drying at 60°C for 10 minutes, and let it cool down naturally.

Embodiment 2

[0028] Put 10,000 extra-grade natural corks into the drum, heat while rolling, so that the corks are evenly heated and preheated to a surface temperature of 40°C; spray 5L on the surface of the preheated corks with a mass percentage concentration of 28 % of acrylic resin aqueous solution, the spraying rate is 1.0L / min, and the spraying pressure is 0.2MPa; the roller is rolled to make the acrylic resin aqueous solution evenly rolled on the cork, and heated until the surface temperature of the cork is 50°C , keep the drum rolling, and keep drying at 50°C for 10 minutes, and cool naturally; that is.

Embodiment 3

[0030] Put 10,000 extra-grade natural corks into the drum, and heat while rolling, so that the corks are evenly heated and preheated to a surface temperature of 20°C; spray 3L on the surface of the preheated corks with a mass percentage concentration of 22 % of acrylic resin aqueous solution, the spraying rate is 1.0L / min, and the spraying pressure is 0.4MPa; the roller is rolled to make the acrylic resin aqueous solution evenly rolled on the cork, and heated until the surface temperature of the cork is 70°C , keep the drum rolling, and keep drying at 70°C for 5 minutes, and cool naturally; that is.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com