A kind of preparation method of hollow palladium nanosphere

A palladium nanometer and nanosphere technology, which is applied in the field of preparation of hollow palladium nanospheres, can solve problems such as reducing palladium and palladium reserves, and achieve the effects of high product yield, excellent electrocatalytic activity and stability, and good uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of cuprous oxide nanospheres

[0030] Take 1mL of 0.05mol / L CuCl 2 Aqueous solution, 0.2mL 0.5mol / L polyethylenimine aqueous solution with a number average molecular weight of 600, 0.6mL 0.1mol / L ascorbic acid aqueous solution, add 10mL distilled water, stir and mix for 3 minutes, adjust with 0.5mol / L sodium hydroxide aqueous solution The pH value of the obtained mixed solution was 11.5, and stirred at room temperature for 20 minutes to obtain a cuprous oxide nanosphere solution.

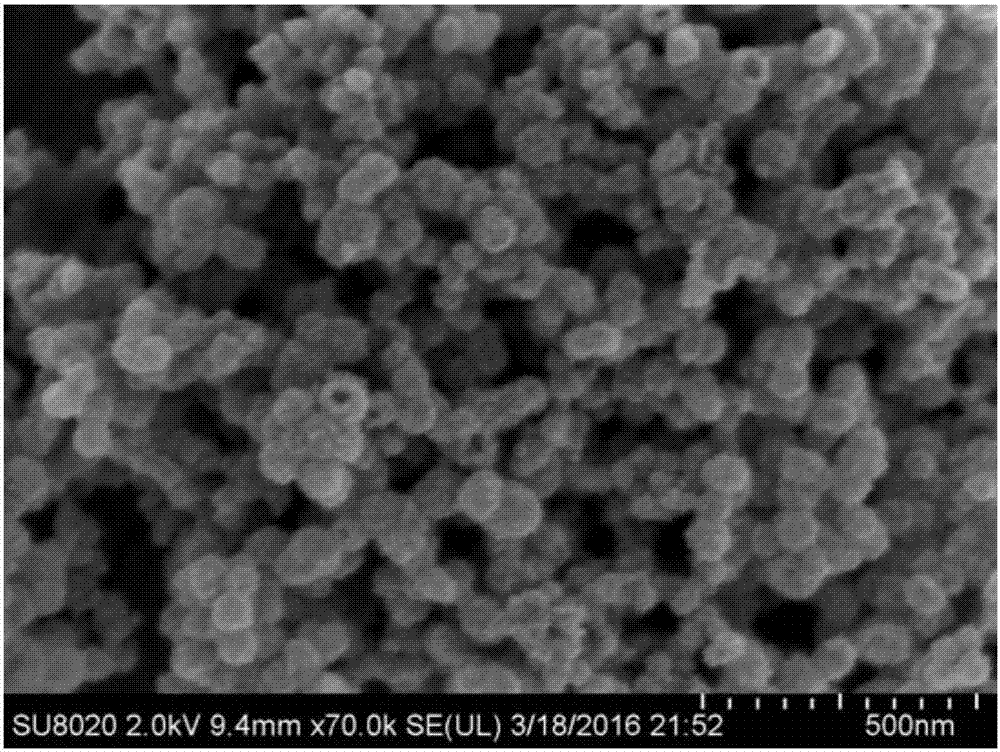

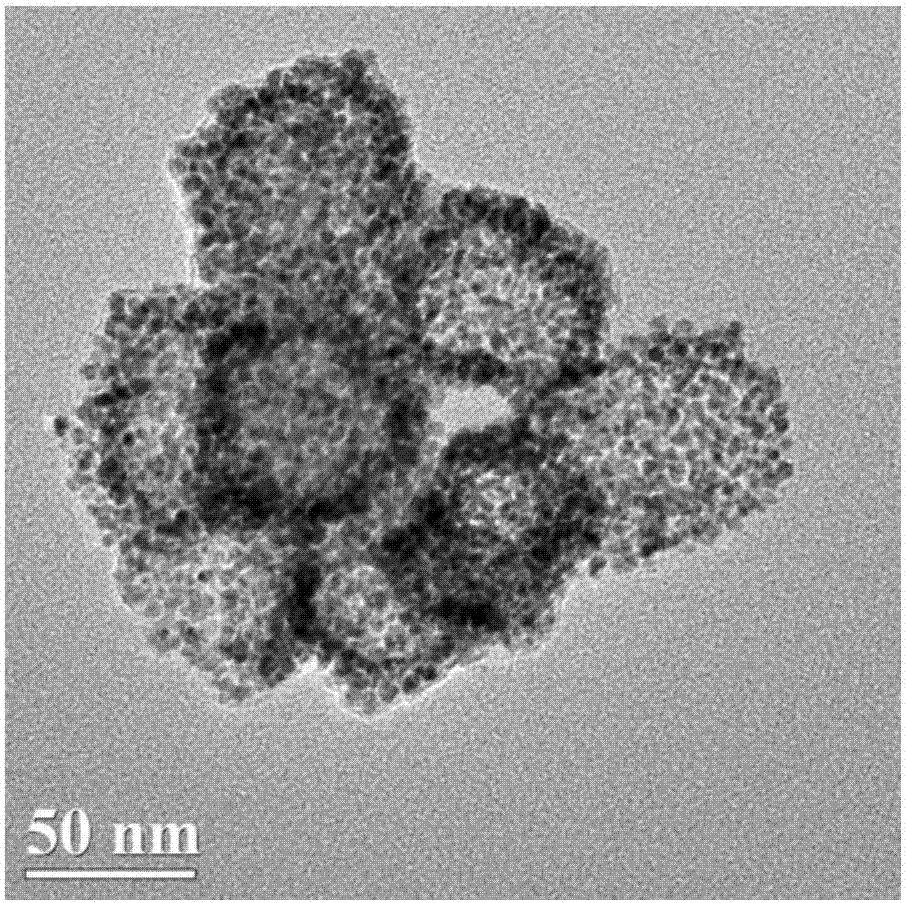

[0031] 2. Preparation of hollow palladium nanospheres

[0032] After adjusting 0.45mL of 0.06mol / L potassium chloropalladate aqueous solution to pH 11.5 with 0.5mol / L sodium hydroxide aqueous solution, add it to the cuprous oxide nanosphere solution obtained in step 1, and add 15.5 μL mass fraction It is 80% hydrazine hydrate aqueous solution, heated to 60 DEG C in water bath, constant temperature reduction reaction for 30 minutes, then stirred at room temperature for 24 hour...

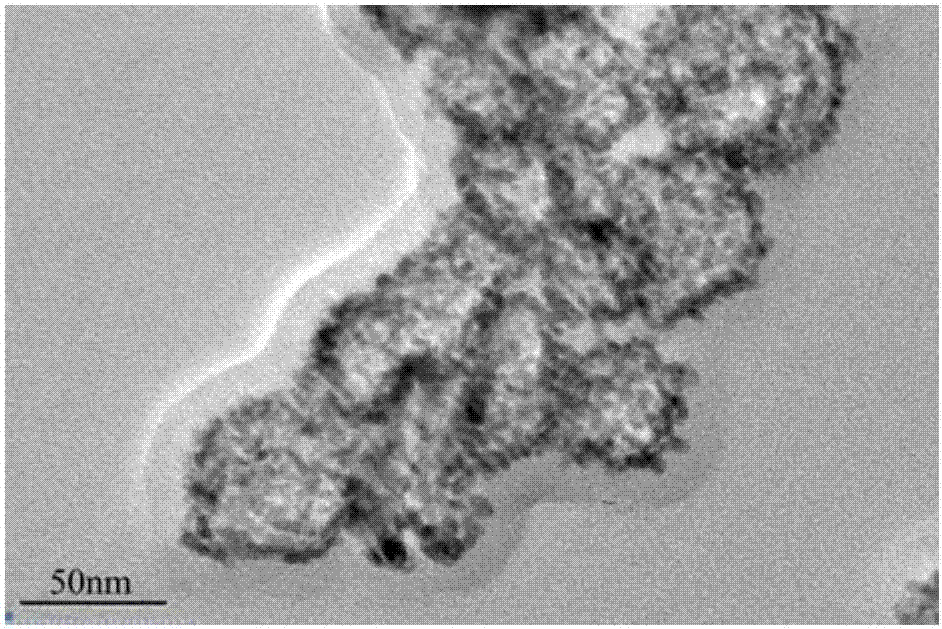

Embodiment 2

[0034] In Example 1, the copper chloride used is replaced with equimolar copper sulfate, and potassium chloropalladate is replaced with equimolar palladium chloride, and other steps are the same as in Example 1 to obtain hollow palladium nanospheres (see image 3 ).

Embodiment 3

[0036]In Example 1, 0.2 mL of 0.5 mol / L polyethyleneimine aqueous solution with a number average molecular weight of 600 was replaced with 0.1 mL of 0.5 mol / L polyethyleneimine aqueous solution with a number average molecular weight of 600, and other steps were the same as in Example 1 , to obtain hollow palladium nanospheres (see Figure 4 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com