A new process of two-step treatment and reuse of pva-containing desizing wastewater

A technology of desizing wastewater and new technology, which is applied in textile industry wastewater treatment, water/sewage multi-stage treatment, heating water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

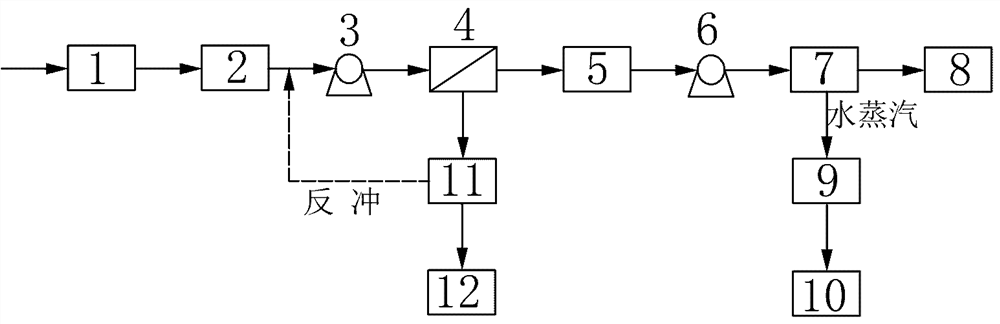

[0036] 1) Concentration of PVA-containing desizing wastewater by membrane separation method: pump desizing wastewater containing 0.5% PVA into the fine filter (1), filter through the fine filter (1) and collect it in the wastewater collection pool (2), through self-priming The pump (3) is pumped into the membrane separation device (4), at a temperature of 30 o C, the pressure in the membrane is 0.02MPa, the membrane separation device (4) is operated for 30min and backwashed for 20s, and concentrated 10 times to obtain a first-grade PVA concentrate containing 5% by weight and a COD1400mg / L permeate; a first-grade PVA concentrate Enter the primary PVA concentrated liquid collection tank (5); the permeate enters the permeate collection tank (11), and too much permeate enters the PVA replenishment tank (12).

[0037] 2) Pump the first-grade PVA concentrated liquid concentrated by the membrane separation system into the distillation tank (7) through the self-priming pump (6), at a ...

Embodiment 2

[0039] 1) Concentration of PVA-containing desizing wastewater by membrane separation method: pump desizing wastewater containing 1% PVA into the fine filter (1), filter through the fine filter (1) and collect it in the wastewater collection pool (2), through self-priming The pump (3) is pumped into the membrane separation device (4), at a temperature of 50 o C, membrane internal pressure 0.06MPa, membrane separation device (4) running 20min and backwashing 25s conditions, concentrate 6 times, get the first-grade PVA concentrated solution containing 6% by weight and COD1000mg / L permeate; first-grade PVA concentrated solution Enter the primary PVA concentrated liquid collection tank (5), the permeate enters the permeate collection tank (11), and too much permeate enters the PVA replenishment tank (12).

[0040] 2) Pump the primary PVA concentrated liquid concentrated by the membrane separation system into the distillation tank (7) through the self-priming pump (6), at a temperat...

Embodiment 3

[0042] 1) Concentration of PVA-containing desizing wastewater by membrane separation method: pump desizing wastewater containing 2% PVA into the fine filter (1), filter through the fine filter (1) and collect it in the wastewater collection tank (2), through self-priming The pump (3) is pumped into the membrane separation device (4), at a temperature of 70 o C, the pressure in the membrane is 0.08MPa, the membrane separation device (4) is operated for 15min and backwashed for 30s, concentrated 3.5 times, and the first-grade PVA concentrate containing 7% by weight and the COD are 800mg / L permeate; the first-grade PVA The concentrated solution enters the primary PVA concentrated solution collection tank (5); the permeate enters the permeate collection tank (11), and excessive permeate enters the PVA supplement tank (12).

[0043] 2) Pump the first-grade PVA concentrated liquid concentrated by the membrane separation system into the distillation tank (7) through the self-priming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com