A kind of all-solid waste foamed ceramic insulation board based on ceramic polishing slag and preparation method thereof

A technology of ceramic polishing slag and foamed ceramics, which is applied in the fields of green building materials and building energy conservation, can solve the problems of difficulty in reducing production costs, reducing the production cost of foamed ceramics, and consuming non-renewable mineral resources. The performance index is stable and controllable, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

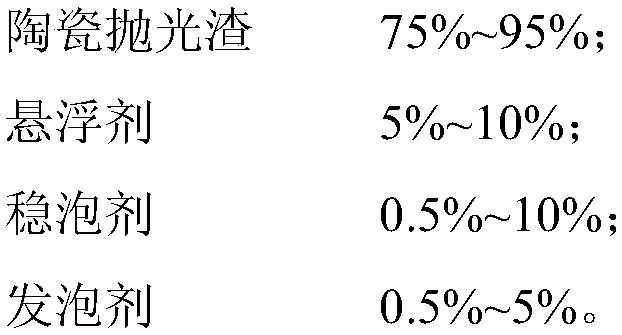

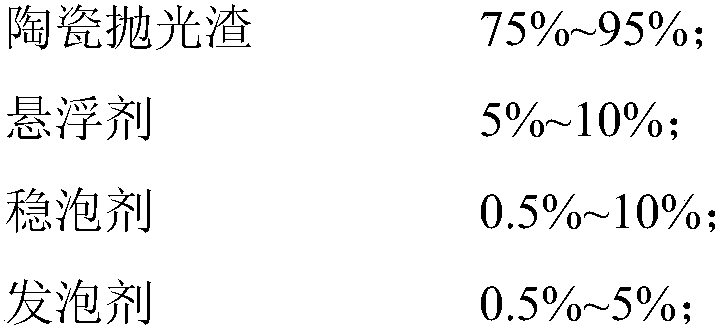

[0024] In this example, the raw materials and proportions used to prepare the all-solid waste foamed ceramic insulation board based on ceramic polishing slag are:

[0025] The weight ratio of solid waste powder to water is 1:0.4, and the weight percentage of each component in the solid waste powder is: polishing slag 87%, laterite 10%, blast furnace dust 2.65%, SiC dust removal powder 0.35% .

[0026] The method for preparing a foamed ceramic insulation board by using the above-mentioned raw materials comprises the following steps:

[0027] 1) Homogenization treatment of raw materials: Homogenize polishing slag, laterite, blast furnace ash, and SiC dedusting powder in the storage yard to obtain four kinds of powder materials for future use.

[0028] 2) Slurry preparation: mix the four powders obtained in step (1) in proportion, then add water in proportion, and perform wet ball milling with a ball mill for 6 hours to obtain the slurry;

[0029] 3) Spray drying: After sieving...

Embodiment 2

[0036] In this example, the raw materials and proportions used to prepare the all-solid waste foamed ceramic insulation board based on ceramic polishing slag are:

[0037] The weight ratio of solid waste powder to water is 1:0.5, and the weight percentage of each component in the solid waste powder is: polishing slag 87.5%, oil shale 6.5%, converter dust 3.5%, waste gypsum powder 2.5%.

[0038] The method for preparing a foamed ceramic insulation board by using the above-mentioned raw materials comprises the following steps:

[0039] 1) Uniform raw materials: Homogenize four raw materials, including polishing slag, oil shale, converter ash, and waste gypsum powder, in the storage yard to obtain four kinds of powder materials for future use.

[0040]2) Slurry preparation: Mix the four kinds of powders obtained in step (1) in proportion, then add water in proportion, and perform wet ball milling with a ball mill for 12 hours to obtain the slurry;

[0041] 3) Spray drying: Afte...

Embodiment 3

[0048] In this example, the raw materials and proportions used to prepare the all-solid waste foamed ceramic insulation board based on ceramic polishing slag are:

[0049] The weight ratio of solid waste powder to water is 1:0.6, and the weight percentage of each component in the solid waste powder is: polishing slag 84.5%, coal gangue 10%, blast furnace dust 5%, SiC dust removal powder 0.5% %.

[0050] The method for preparing a foamed ceramic insulation board by using the above-mentioned raw materials comprises the following steps:

[0051] 1) Uniformity of raw materials: four kinds of raw materials such as polishing slag, coal gangue, blast furnace ash, and SiC dedusting powder are uniformly processed in the storage yard to obtain four kinds of powder materials for future use.

[0052] 2) Slurry preparation: Mix the four kinds of powders obtained in step (1) in proportion, then add water in proportion, and perform wet ball milling with a ball mill for 12 hours to obtain th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com