Method for preparing polyhydroxyethyl methacrylate-titanium dioxide nanometer hybrid material

A technology of poly(hydroxyethyl methacrylate) and hydroxyethyl methacrylate, which is applied in the field of preparing poly(hydroxyethyl methacrylate-titanium dioxide) nano-hybrid materials, which can solve limitations, copper quenching fluorescence, copper ion residues, etc. problem, to achieve the effect of reducing copper ion residue, good density chain and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

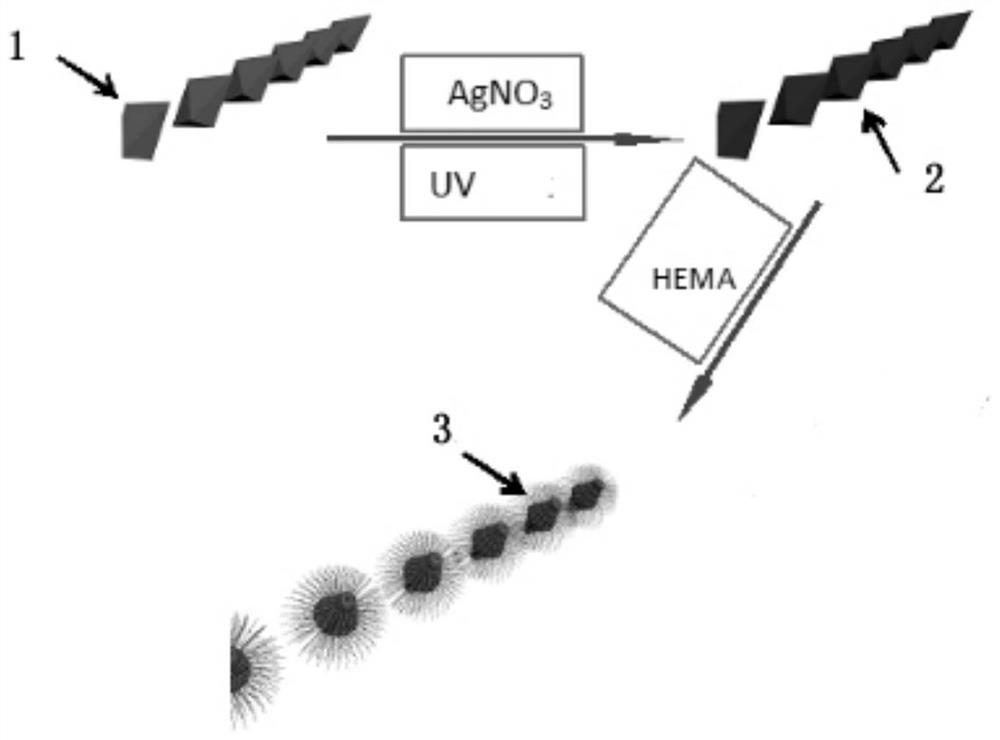

[0057] The method for preparing polyhydroxyethyl methacrylate-titanium dioxide nano-hybrid material comprises the following steps:

[0058] S1. Preparation of nano-titanium dioxide with silver loaded on the surface: under ultraviolet light irradiation, silver is loaded on the surface of nano-titanium dioxide;

[0059] S2. Preparation of poly(hydroxyethyl methacrylate-titanium dioxide nano-hybrid material): under visible light, active polymerization of hydroxyethyl methacrylate is initiated on the surface of nano-titanium dioxide loaded with silver on the surface prepared in S1 to obtain a hybrid material.

Embodiment 2

[0061] The method for preparing polyhydroxyethyl methacrylate-titanium dioxide nano-hybrid material comprises the following steps:

[0062] S1. Preparation of nano-titanium dioxide with silver loaded on the surface: under ultraviolet light irradiation, silver is loaded on the surface of nano-titanium dioxide;

[0063] S2. Preparation of poly(hydroxyethyl methacrylate-titanium dioxide nano-hybrid material): under visible light, active polymerization of hydroxyethyl methacrylate is initiated on the surface of nano-titanium dioxide loaded with silver on the surface prepared in S1 to obtain a hybrid material.

[0064] The nano titanium dioxide is prepared by the following method: taking butyl phthalate, oleic acid, oleylamine and ethanol to prepare shuttle nano titanium dioxide through a hydrothermal method.

Embodiment 3

[0066] S1, the preparation of the nano-titanium dioxide of surface loading silver, specifically comprises the following steps:

[0067] S1.1. Dispersing nano-titanium dioxide in tetrahydrofuran to obtain a nano-titanium dioxide solution for subsequent use; wherein, the concentration of the nano-titanium dioxide solution is 0.28 g / mL;

[0068] S1.2. Add silver nitrate solution to the nano-titanium dioxide solution, mix well, and seal after 12 minutes of nitrogen gas; wherein, the silver nitrate solution refers to the tetrahydrofuran solution of silver nitrate, and the concentration of the silver nitrate solution is 0.008mol / L; according to the volume ratio , nano-titanium dioxide solution: silver nitrate solution=11: 7;

[0069] S1.3. Illuminate for 5 minutes under ultraviolet light to obtain silver-loaded nano-titanium dioxide on the surface;

[0070] S2, the preparation of polyhydroxyethyl methacrylate-titanium dioxide nano-hybrid material, specifically comprises the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com