A kind of naphthalene series ceramic dispersant and preparation method thereof

A ceramic dispersant and naphthalene-based technology, which is applied in the field of ceramic dispersant preparation, can solve the problems of side effects, easy solidification, and narrow degumming range, and achieve good fluidity and viscosity, simple production process, and easy control of conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

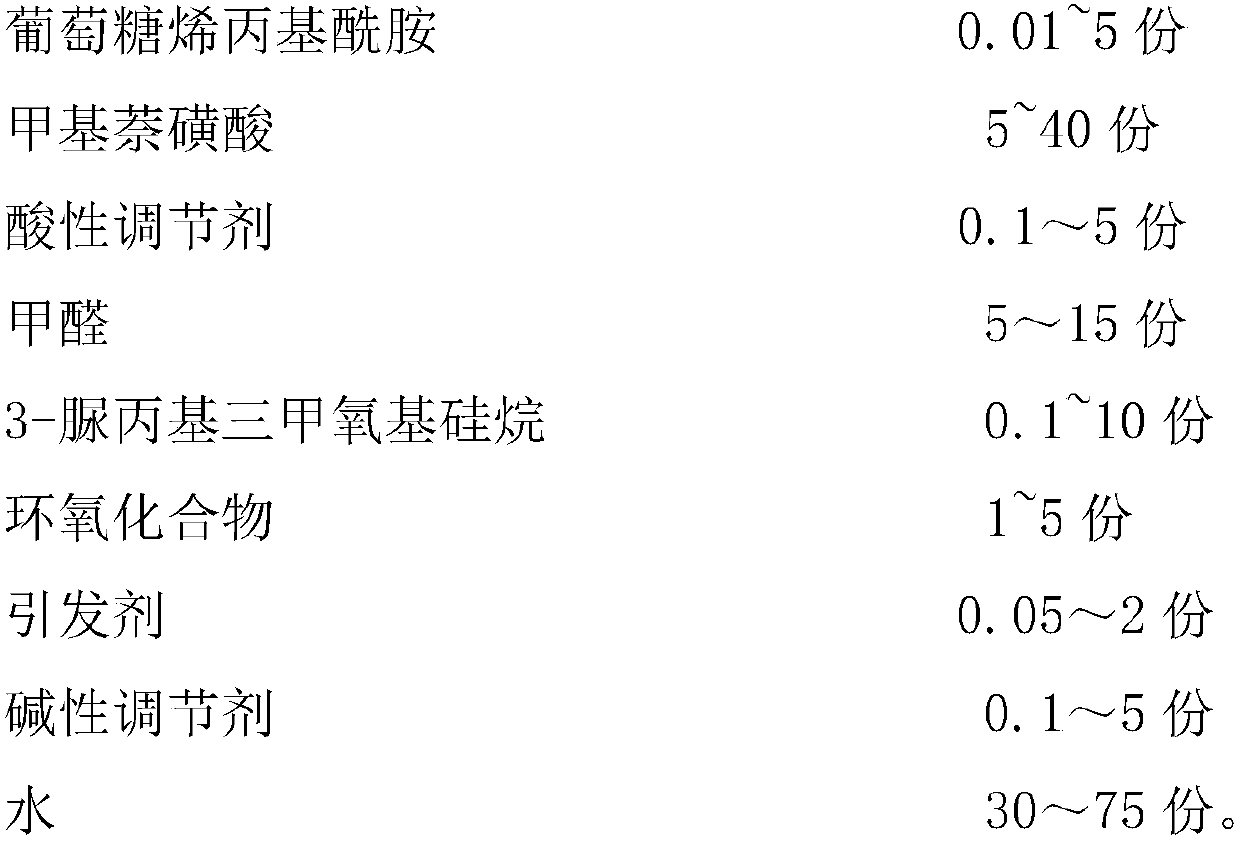

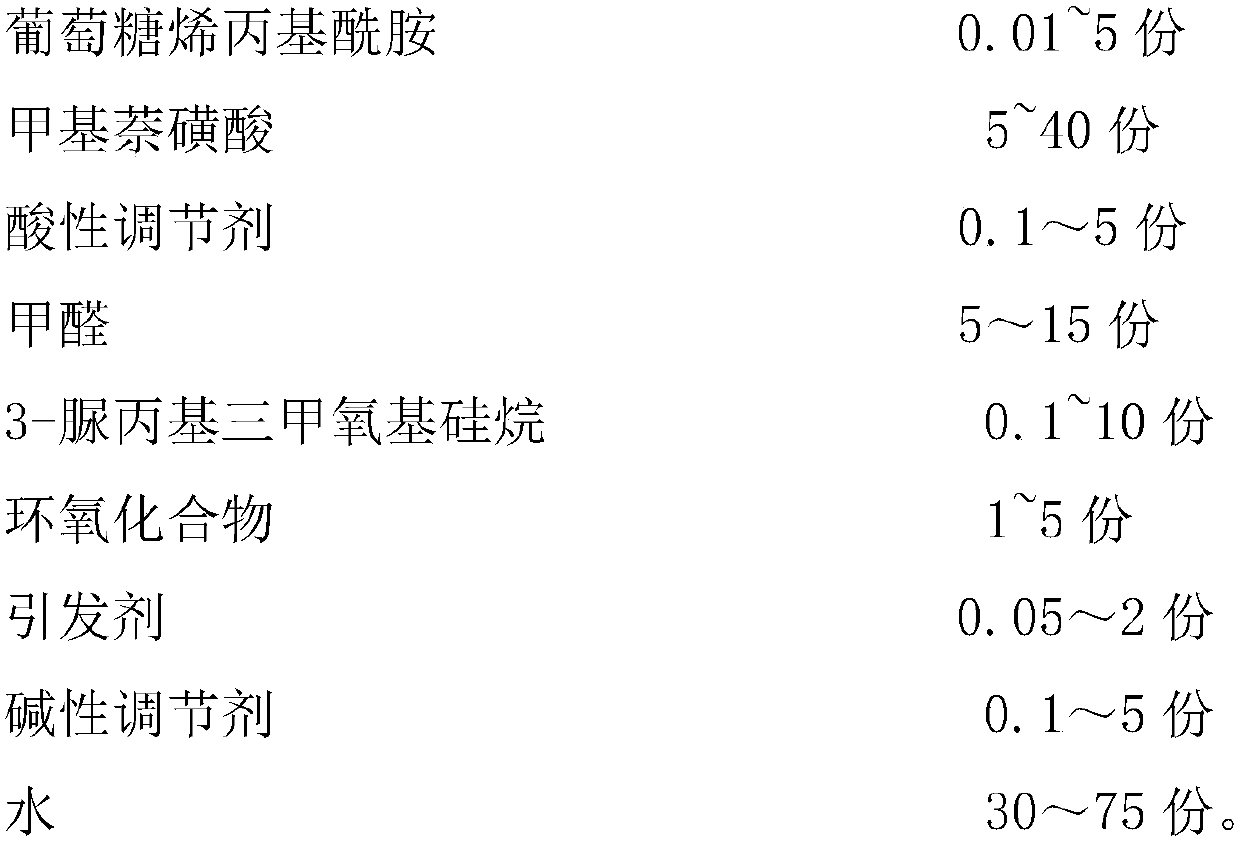

[0022] A kind of preparation method of naphthalene-based ceramic dispersant of the present invention is made of the following raw material components in proportions by weight:

[0023]

[0024] The acid regulator is any one of amino trimethylene phosphonic acid, ethylenediamine tetramethylene phosphonic acid, hexamethylenediamine tetramethylene phosphonic acid or a mixture of two or more mixed in any ratio;

[0025] The epoxy compound is any one of allyl glycidyl ether, allyl polyoxyethylene epoxy ether and allyl polyoxyethylene polyoxypropylene epoxy ether or two or more are mixed in any ratio mixture;

[0026] The initiator is any one of sodium persulfate, potassium persulfate and ammonium persulfate or a mixture of two or more in any ratio.

[0027] The alkaline conditioner is any one of sodium hydroxide, potassium hydroxide, sodium carbonate and potassium carbonate or a mixture of two or more mixed in any ratio.

[0028] A preparation method of a naphthalene series ce...

Embodiment 1

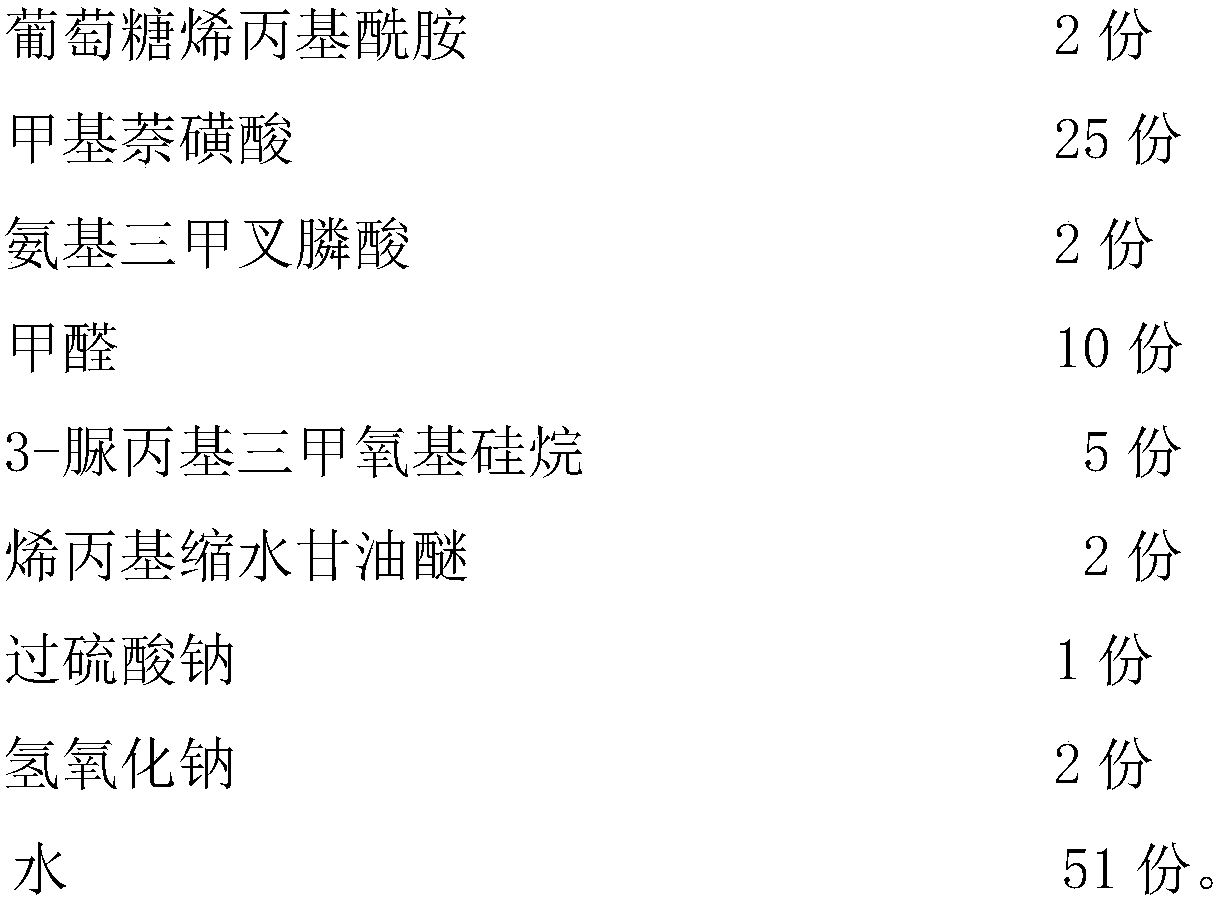

[0035] A kind of naphthalene-based ceramic dispersant is made from the following raw material components in parts by weight:

[0036]

[0037] Its preparation method is realized through the following steps:

[0038] (1) After adding 2 parts of glucose allylamide, 25 parts of methyl naphthalene sulfonic acid, 2 parts of aminotrimethylene phosphonic acid and 32 parts of water into the reactor, start stirring, and start heating;

[0039] (2) When the temperature rises to 98°C, start to add 10 parts of formaldehyde dropwise for 3 hours;

[0040] (3) add 5 parts of 3-ureapropyl trimethoxysilanes, 2 parts of allyl glycidyl ethers in the reaction kettle again, start to drip the sodium persulfate solution that the mass percent concentration is 5% after waiting to stir evenly, this The sodium persulfate solution is prepared from 1 part of sodium persulfate and 19 parts of water; the dropping time is controlled at 3 hours, and the temperature is controlled at 105°C during the droppi...

Embodiment 2

[0043] A kind of naphthalene-based ceramic dispersant is made from the following raw material components in parts by weight:

[0044]

[0045] Its preparation method is realized through the following steps:

[0046] (1) Add 3 parts of glucose allylamide, 30 parts of methyl naphthalene sulfonic acid, 2 parts of aminotrimethylene phosphonic acid and 22 parts of water into the reactor, start stirring, and start heating;

[0047] (2) When the temperature rises to 105°C, start to add 12 parts of formaldehyde dropwise for 3.5 hours;

[0048] (3) Add 2 parts of 3-ureapropyl trimethoxysilane and 2 parts of allyl polyoxyethylene epoxy ether to the reaction kettle, and start to drop persulfuric acid with a mass percentage concentration of 4% after stirring evenly Sodium solution, the sodium persulfate solution is prepared from 1 part of sodium persulfate and 24 parts of water; the dropping time is controlled at 2 hours, and the temperature is controlled at 110 ° C during the droppin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com