Detection method for sulfur content in sulfur cream

A detection method and technology for sulfur content, applied in the direction of chemical analysis by titration, can solve the problems of low efficiency, easy volatility and high risk, and achieve the effects of convenient operation, improved cleanliness and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] First, sample the sulfur paste to be detected, then dry the sample, weigh the dry sample to 0.1031g, then put the sample into a flask, then add 50mL of alcohol to the flask, then add 80mL of distilled water, then add 10g of sodium sulfite, and then heat back to Distill until all the samples in the flask are dissolved, then add distilled water to make up to 250mL, draw 50ml into a 250mL Erlenmeyer flask, add 10mL of formaldehyde, 20mL of 10% acetic acid, 4 drops of starch indicator, and titrate with 0.1mol / L iodine standard solution , the volume of iodine standard solution consumed is 5.75mL.

[0037] Sulfur content calculation: 0.1mol / L×5.75mL×32g / mol×5×100%÷0.1031g÷1000=89.23%.

Embodiment 2

[0038] Embodiment 2 precision and accuracy experiment

[0039] Precision refers to the degree to which the results of repeated measurements under the same conditions are consistent with each other. The size of the precision is expressed by the relative standard deviation. The smaller the deviation, the higher the precision.

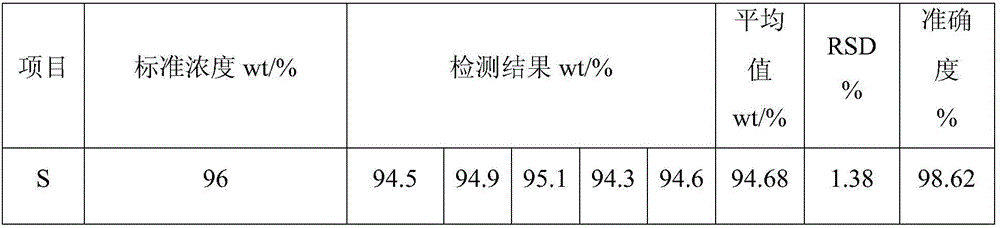

[0040] Adopt analytically pure sulfur powder to add sand preparation standard concentration to be the sample of 96%, adopt method provided by the invention then to the same sample parallel measurement of the sample of above-mentioned standard concentration 5 times, then calculate the relative standard deviation of measurement result, The results are described in Table 1.

[0041] The detection result of table 1 embodiment of the present invention precision and accuracy

[0042]

[0043] From the above test results, the accuracy and accuracy of the method are good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com