Method for preparing tetrabasic lead sulfate with small grain size with sol-gel method

A tetrabasic lead sulfate, sol-gel technology, applied in lead sulfate, lead-acid battery electrodes, structural parts, etc., can solve problems such as the decrease in specific capacity, and achieve the effects of preventing agglomeration, high product purity, and uniform dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1.1. Weigh 6.5g of lead acetate and 7.68g of citric acid complexing agent (molar ratio 1:2), dissolve them in 100mL of distilled water under the condition of stirring in a water bath at 90°C, add 0.58g of sulfuric acid solution with a mass concentration of 51%, After the fumed silica dispersant of 0.28g, lead oxide / lead sulfate sol is obtained;

[0033] 1.2. Continue to stir the lead oxide / lead sulfate sol obtained in step 1.1 in a water bath at 90°C, and evaporate to dryness to obtain lead oxide / lead sulfate xerogel;

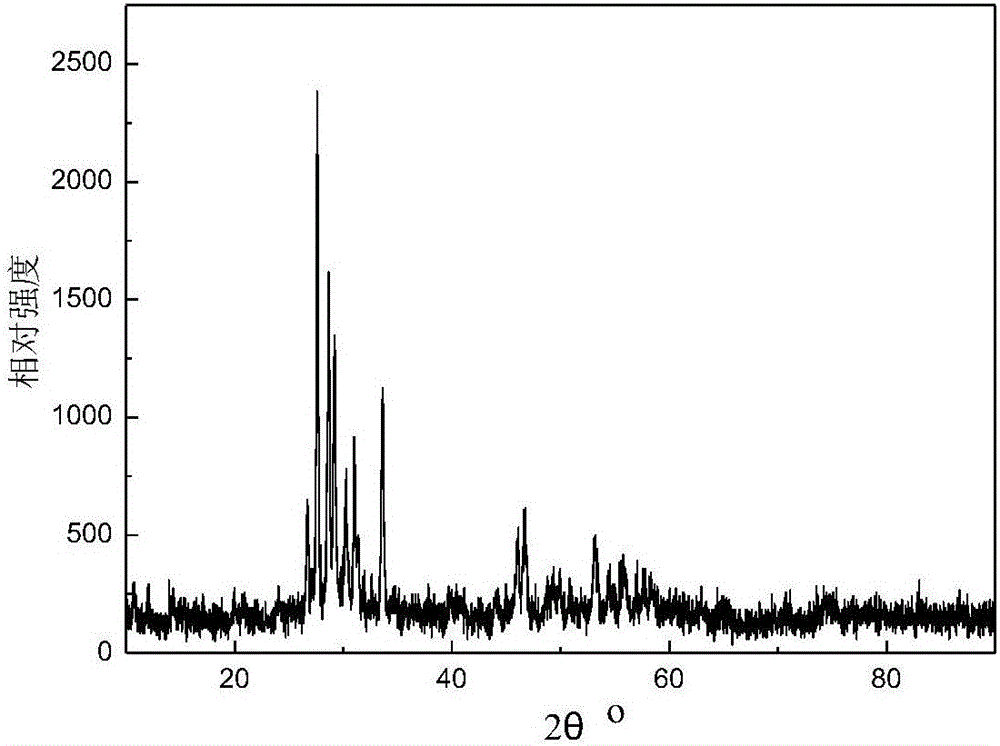

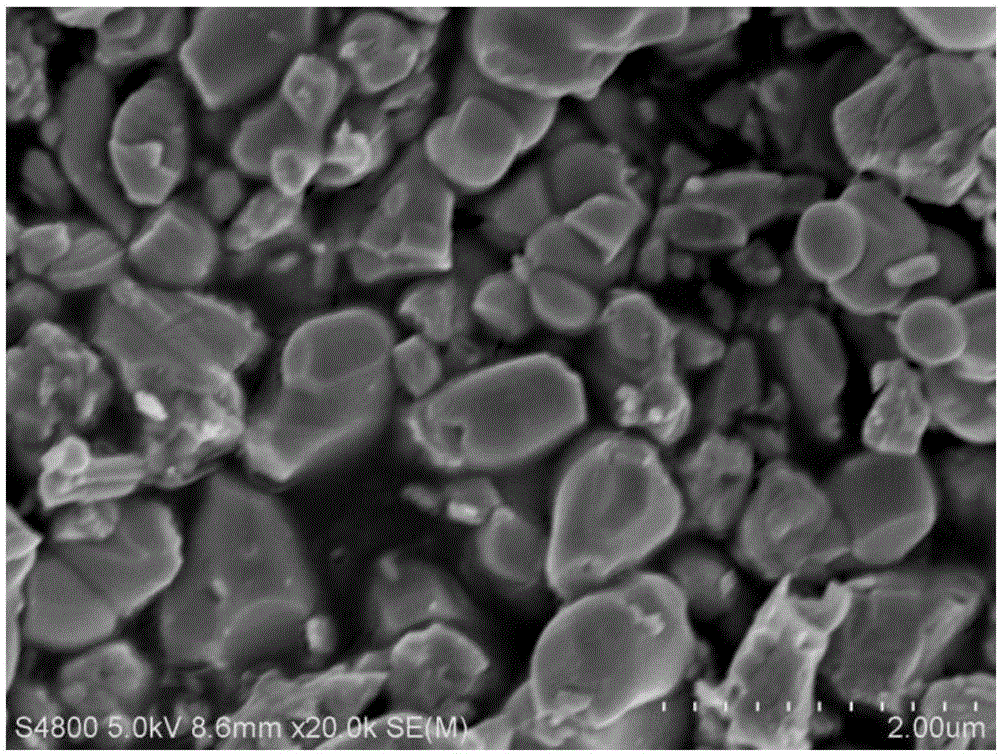

[0034] 1.3. The lead oxide / lead sulfate xerogel obtained in step 1.2 was pre-sintered at 150°C for 3.5 hours at a low temperature and sintered at a high temperature at 500°C for 5 hours in an air atmosphere to obtain tetrabasic lead sulfate powder;

[0035] 1.4. After grinding the powder obtained in step 1.3, pass through a 200-mesh sieve to obtain tetrabasic lead sulfate (4BS). The grain size of the tetrabasic lead sulfate is 500 nm-1 μm.

[0036] The...

Embodiment 2

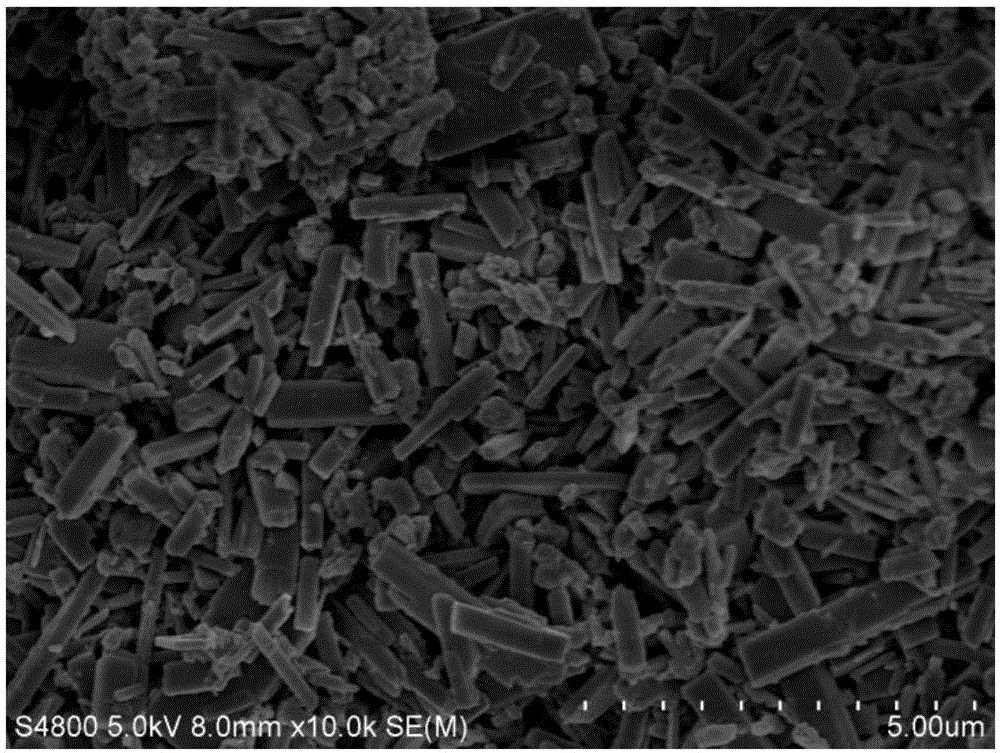

[0042] 1.1. Weigh 6.5g of lead acetate and 17.53g of EDTA complexing agent (molar ratio 1:3), dissolve them in 100mL of distilled water under the condition of stirring in a water bath at 80°C, add 0.20g of sulfuric acid solution with a mass concentration of 60%, 0.13 After the fumed silica dispersant of g, continue to stir, obtain plumbous oxide / lead sulfate sol;

[0043] 1.2. Continue to evaporate the lead oxide / lead sulfate sol obtained in step 1.1 under the condition of stirring in an 80°C water bath to obtain lead oxide / lead sulfate xerogel;

[0044] 1.3. The lead oxide / lead sulfate xerogel obtained in step 1.2 was pre-sintered at 200°C for 2 hours at a low temperature and sintered at a high temperature at 400°C for 6 hours in an air atmosphere to obtain tetrabasic lead sulfate powder;

[0045] 1.4. After grinding the powder obtained in step 1.3, pass through a 200-mesh sieve to obtain tetrabasic lead sulfate (4BS).

Embodiment 3

[0047] 1.1. Weigh 6.5g of lead acetate and 3.84g of citric acid complexing agent (molar ratio 1:1), dissolve them in 100mL of distilled water under the condition of stirring in a water bath at 85°C, add 0.58g of sulfuric acid solution with a mass concentration of 15%, After the aluminum oxide dispersant of 0.39g, obtain plumbous oxide / lead sulfate sol;

[0048] 1.2. Continue to stir the lead oxide / lead sulfate sol obtained in step 1.1 in a water bath at 85°C, and evaporate to dryness to obtain lead oxide / lead sulfate xerogel;

[0049] 1.3. The lead oxide / lead sulfate xerogel obtained in step 1.2 was pre-sintered at 550°C for 1.5 hours at a low temperature and sintered at a high temperature at 300°C for 7 hours in an air atmosphere to obtain tetrabasic lead sulfate powder;

[0050] 1.4. After grinding the powder obtained in step 1.3, pass through a 200-mesh sieve to obtain tetrabasic lead sulfate (4BS).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com