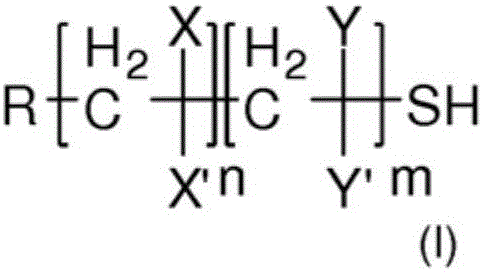

Polyphosphorus polymer that is thiol-functionalised at the chain ends and production method thereof

A technology of polymers and polymer chains, applied in the field of polyphosphorus-based polymers, can solve the problems of polymer elastomer property degradation and performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

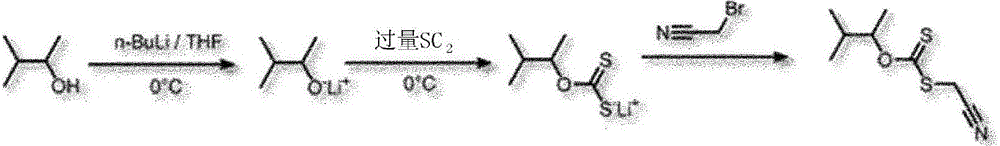

[0111] Example 1: Synthesis of xanthates with C4 cyanomethyl functional groups

[0112] - Reaction scheme

[0113]

[0114] Scheme 1. Synthesis of xanthates with C4 cyanomethyl functional groups

[0115] 6g (6.81x 10 -2mol) 3-methylbutanol was dissolved in 45ml THF. BuLi solution (1.6M in hexane) (46.5ml, 7.44x 10 -2 mol) was added dropwise to the reaction mixture at 0 °C. It was allowed to react with stirring for 30 minutes. Carbon disulfide (30ml, 4.96x 10 -1 mol) was added dropwise to the reaction medium at 0°C. The reaction mixture was then maintained at 0 °C for 30 minutes under magnetic stirring. Divide 11.6g (13.62x 10 -2 mol) bromoacetonitrile was added dropwise to the reaction mixture, and then the solution was kept under stirring for 15h. After evaporating THF, pass through CH 2 Cl 2 / water (1:1) to extract and purify the residue. Evaporate CH in vacuo 2 Cl 2 solution. After cleanup and evaporation on a chromatographic column (eluent: petroleum ethe...

Embodiment 2

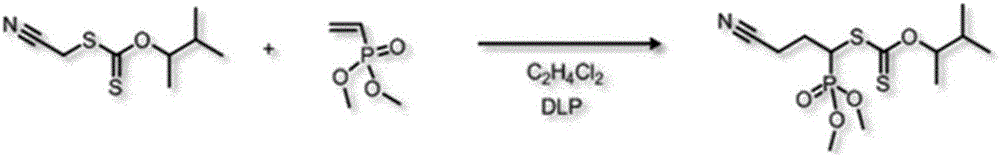

[0118] Example 2: Synthesis of dimethyl vinyl phosphonate DMVP-C4 monoadduct

[0119] - Reaction scheme

[0120]

[0121] Scheme 2. Synthesis of DMVP-C4 monoadduct

[0122] C4 xanthate (2.76g, 13.59x 10 -2 mol), dimethyl vinyl phosphonate (1g, 7.35x 10 - 3 mol) and 1,2-dichloroethane solvent (6ml) were introduced into a 25ml round bottom flask covered with a reflux condenser. The mixture was degassed under argon for 15 minutes. The reaction mixture was then maintained at the reflux point of the solvent (95° C.) for 7 hours with magnetic stirring. 5 mole % dilauroyl peroxide was added every 60 minutes up to 25 mole %. After cleanup on a chromatography column (eluent: ethyl acetate) and evaporation, the final synthesis yield was 65%.

[0123] 1 H NMR (300MHz, CDCl 3 , δ=ppm): 5.58 (1H, m, O-CHCH 3 ), 4.35 (1H, m, NC-CH 2 -CH 2 -CH 1 -S-C=S), 3.82(3H, s, P=(OCH 3 ) 2 ), 2.62 (2H, m, NC-CH 2 -CH 2 -CH 1 -S-C=S), 2.45-2.21 (2H, m, NC-CH 2 -CH 2 -CH 1 -S-C=S)...

Embodiment 4

[0132] Example 4: Pyrolysis of DMVP-C4 monoadduct

[0133] - Reaction scheme

[0134]

[0135] Scheme 4. Pyrolysis of DMVP-C4 monoadduct

[0136] DMVP-C4 monoadduct (250mg, 7.37x 10 -4 mol) and 1,2-dichlorobenzene solvent (3ml) were introduced into a 25ml round bottom flask covered with a reflux condenser. The reaction mixture was degassed under argon for 15 minutes and then kept in the dark at the reflux point of the solvent (200° C.) for 5 minutes. The pyrolysis yield was 70%.

[0137] 31 P NMR (300MHz, CDCl 3 , δ=ppm): 26.3 (1P, s, P=(OCH 3 ) 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com