Methane oxidative coupling reaction catalyst and preparation method thereof

An oxidative coupling reaction and catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of large particle size of active components and carbodicarbon selection It can solve the problems of low performance and low methane conversion rate, and achieve the effects of uniform distribution, improved conversion rate and simple and easy preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

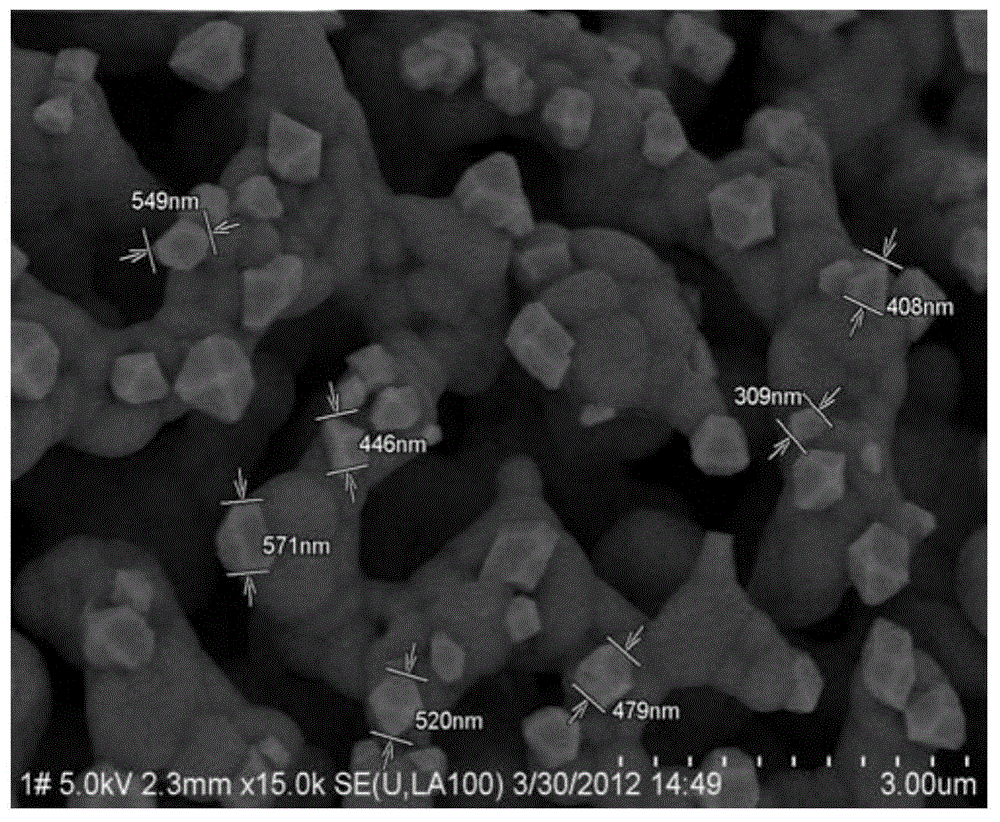

Image

Examples

preparation example Construction

[0015] The preparation method of the methane oxidative coupling reaction catalyst provided by the present invention comprises: under ultrasonic conditions, carrying out the first impregnation of the carrier in the metal compound aqueous solution, drying, and then performing the second impregnation in the metal compound aqueous solution under the ultrasonic conditions , dried and calcined, wherein, the mass ratio of the metal compound in the metal compound aqueous solution to the carrier is 1:0.001-200; the mass ratio of the carrier to the water in the metal compound aqueous solution is 1:1- 20.

[0016] Preferably, the mass ratio of the metal compound in the metal compound aqueous solution to the carrier is 1:0.003-100; the mass ratio of the carrier to water in the metal compound aqueous solution is 1:1-15.

[0017] Further preferably, the mass ratio of the metal compound in the metal compound aqueous solution to the carrier is 1:0.005-50; the mass ratio of the carrier to wate...

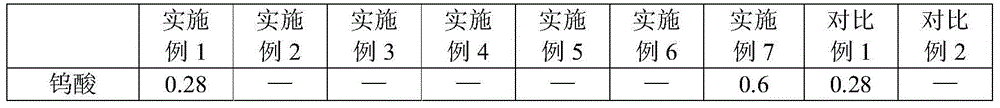

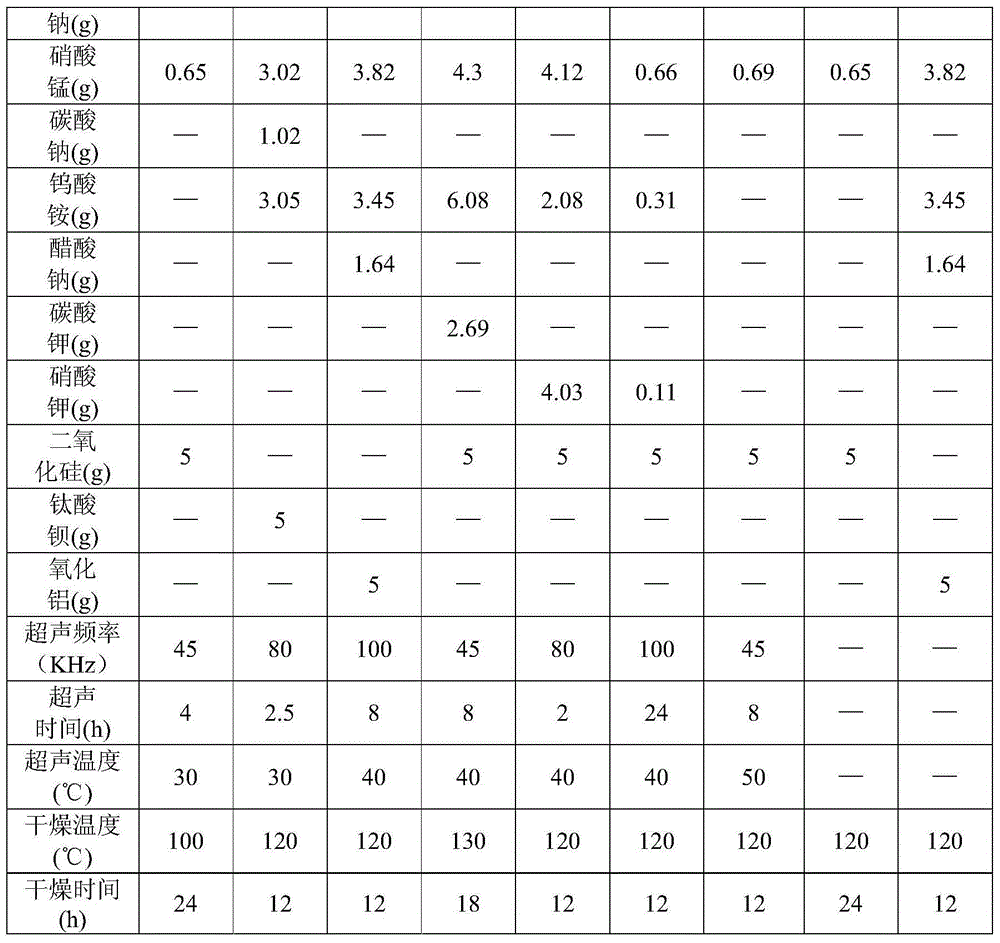

Embodiment 1

[0030]Weigh 0.28g of sodium tungstate and add it into a beaker of 25g of distilled water. After the dissolution is complete, add 5g of silicon dioxide into the beaker, put the beaker into an ultrasonic cleaner, set the ultrasonic frequency to 45KHz, and the ultrasonic temperature to 30°C , sonicated for 4 hours, placed in a constant temperature drying oven at 120°C, and dried for 24 hours to obtain silica loaded with sodium tungstate; weigh 0.65g of manganese nitrate (50% aqueous solution), add it to a beaker of 25g of distilled water, and dissolve it completely , add the above-mentioned silicon dioxide loaded with sodium tungstate to the beaker, put the beaker into an ultrasonic cleaner, set the ultrasonic frequency to 45KHz, ultrasonic temperature to 30°C, ultrasonically treat for 4h, and put it in a constant temperature drying oven at 100°C Dry for 24 hours, move to a muffle furnace for calcination, raise the temperature to 550°C for 5 hours and then continue to raise the te...

Embodiment 2

[0032] Take by weighing 3.02g manganese nitrate (50% aqueous solution), join in the beaker of 10g distilled water, after dissolving completely, add 5g barium titanate in the beaker, put the beaker in the ultrasonic cleaner, set the ultrasonic frequency to 80KHz, ultrasonic The temperature is 30°C, sonicated for 2.5h, put into a constant temperature drying oven at 120°C and dried for 12h to obtain barium titanate loaded with manganese nitrate; weigh 1.02g of sodium carbonate, add it to a beaker of 10g of distilled water, and pour it into Add the above-mentioned barium titanate loaded with manganese nitrate into the beaker, put the beaker into an ultrasonic cleaner, set the ultrasonic frequency to 80KHz, and the ultrasonic temperature to 30°C, ultrasonically treat for 2.5h, and dry in a constant temperature drying oven at 120°C for 12h Obtain the barium titanate that is loaded with sodium carbonate and manganese nitrate; Weigh 3.05g ammonium tungstate, join in the beaker of 10g d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com