A kind of synthetic method of low silicon aluminum ratio zsm-48 molecular sieve

A technology with a low silicon-aluminum ratio and a synthetic method, which is applied in the field of ZSM-48 molecular sieve preparation, can solve the problems of increasing the production cost of zeolite beta, not being able to recycle zeolite, and not having a regular pore structure of zeolite, achieving high crystallinity and reducing Pressure, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 2.35g of sodium aluminate (containing 41wt% Al 2 o 3 and 35wt%Na 2 (2) and 50 mL of water to form a uniform solution, add 21.4 g of white carbon black and stir vigorously, crystallize at 140° C. for 10 days, separate the solid and liquid, and collect the synthetic waste liquid of zeolite beta.

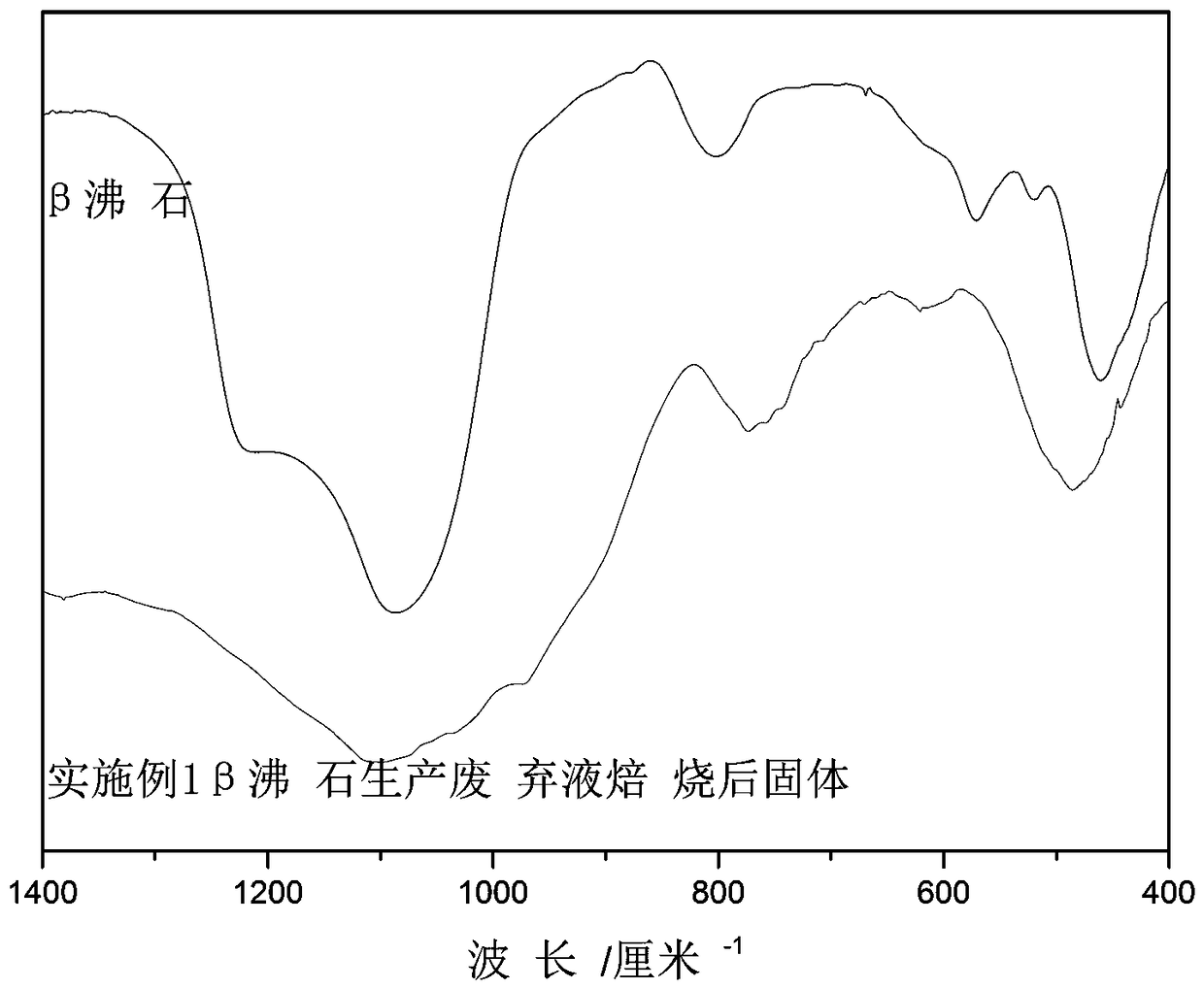

[0025] The above waste liquid contains 3.0wt% SiO 2 , 0.2wt% Na 2 O, 0.01wt% Al 2 o 3 . Take a small amount of waste liquid, evaporate the solvent to dryness, and roast to remove the implicit template agent. The infrared spectroscopic characterization of the calcined solid and β zeolite was compared, and the results were as follows: figure 1 , the 525, 570 cm of β zeolite was not found in the infrared spectrum of the solid obtained by roasting the waste liquid -1 The characteristic peaks indicate that in the collected synthetic waste liquid of zeolite β, the silicon-aluminum elements are not in the form of zeolite β, but in other forms such as primary or secondary st...

Embodiment 2

[0028] 2.68g sodium aluminate (containing 41wt%Al 2 o 3 and 35wt%Na 2O), 22.63g of tetraethylammonium bromide and 1.46g of sodium hydroxide (98wt%) were added to 60mL of water to form a homogeneous solution, and then 23mL of ammonia (27wt%) and 43mL of silica sol (40wt%, pH9) were added under vigorous stirring , 140 ° C crystallization reaction for 8 days, the solid and liquid were separated, and the β zeolite synthesis waste liquid was collected. Waste liquid contains 2.9wt% SiO 2 , 0.2wt% Na 2 O, 0.01wt% Al 2 o 3 .

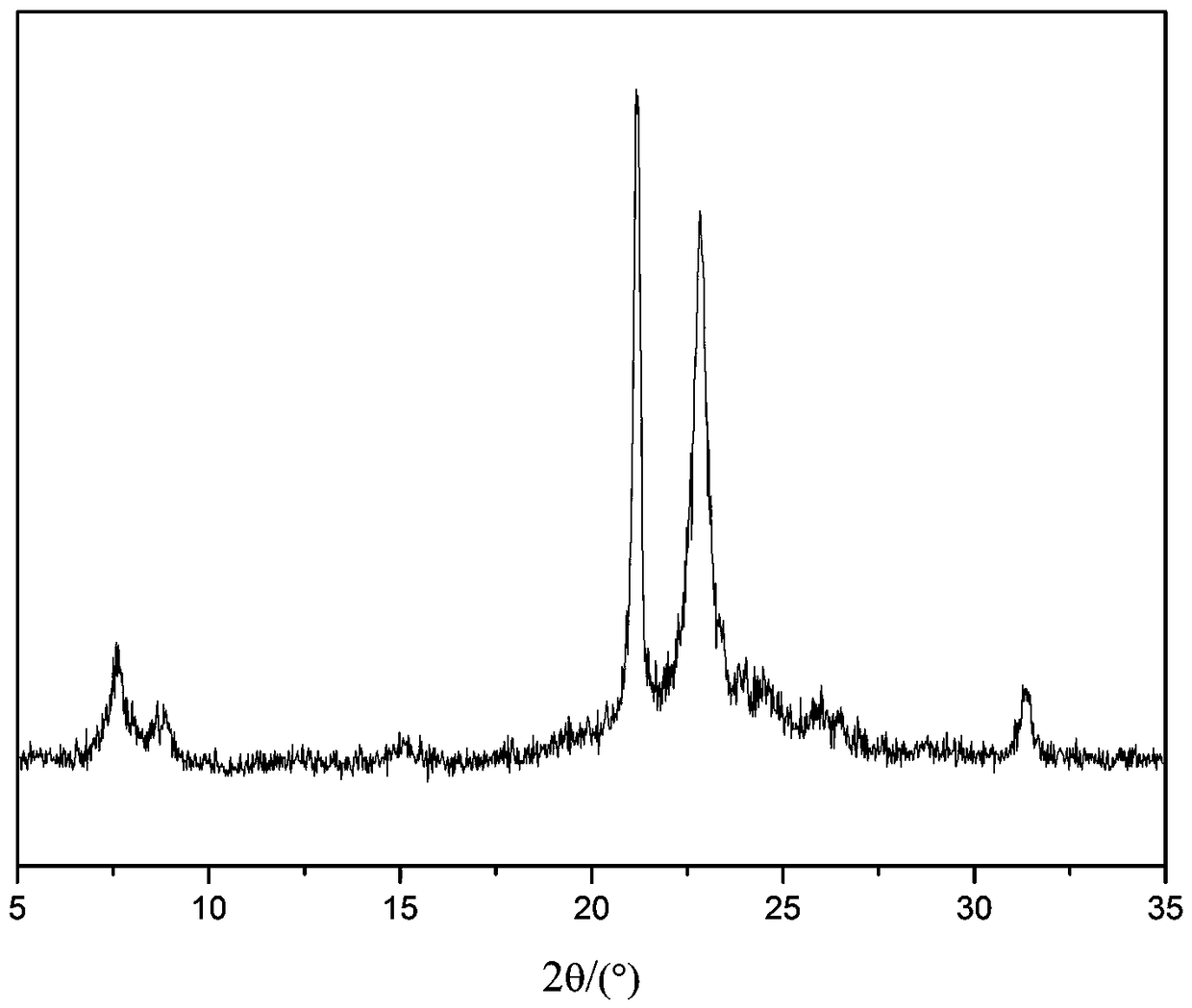

[0029] Get above-mentioned β zeolite synthetic waste liquid 48g and mix with 15mL water, add 1.2g hexamethylammonium bromide, 0.37g sodium metaaluminate (containing 45wt% Al 2 o 3 and 42.6wt%Na 2 O), 0.63g sodium hydroxide are made into solution, then add 8.8g gas phase SiO 2 , stirred evenly, put into a reaction kettle lined with polytetrafluoroethylene, and crystallized at 160°C for 48 hours. After the crystallization was complete, it was rapidly co...

Embodiment 3

[0031] 2.48g sodium aluminate (containing 41wt%Al 2 o 3 and 35wt%Na 2 O), 20.16g of tetraethylammonium bromide and 1.6g of sodium hydroxide were added into 92mL of water to form a homogeneous solution, and then 20.16g of white carbon black was added, stirred evenly and then crystallized at 140°C for 10 days, separated from solid and liquid, and collected to obtain β Zeolite synthesis waste liquid.

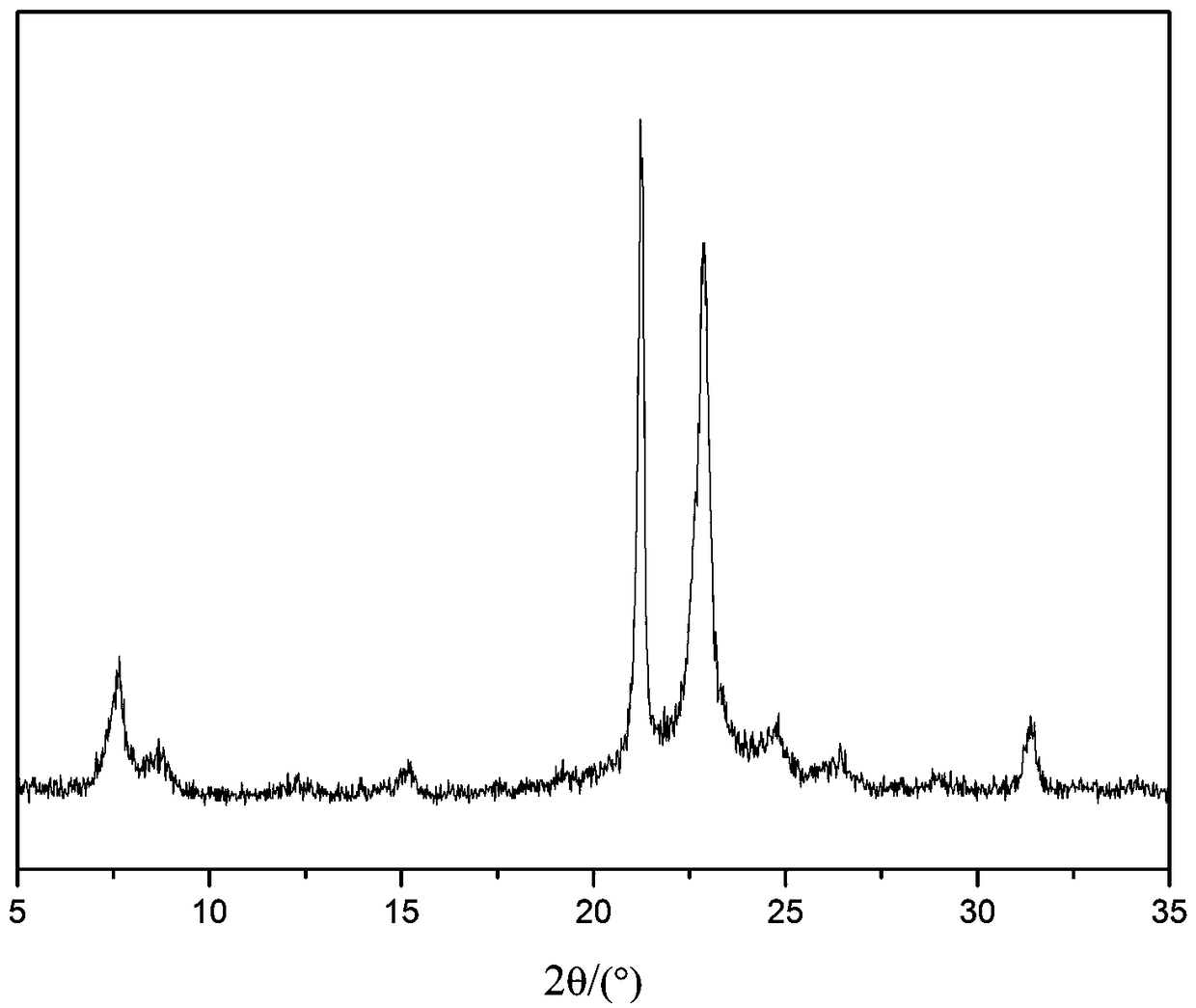

[0032] Take 48g of the above-mentioned synthetic waste liquid of zeolite beta, mix it with 12mL of water, add 1.02g of hexamethylammonium bromide, 0.39g of sodium metaaluminate (containing 45wt% Al 2 o 3 and 42.6wt%Na 2 O), 0.78g sodium hydroxide are made into solution, then add 9g gas phase SiO 2 , stirred evenly, put into a reaction kettle lined with polytetrafluoroethylene, and crystallized at 160°C for 72 hours. After the crystallization was complete, it was rapidly cooled to room temperature, centrifuged and washed to obtain a solid product. It is a pure phase ZSM-48 mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com