Dielectric ceramic composition and ceramic electronic device

A technology of dielectric ceramics and compositions, applied in the field of dielectric ceramic compositions, can solve problems such as reliability reduction, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

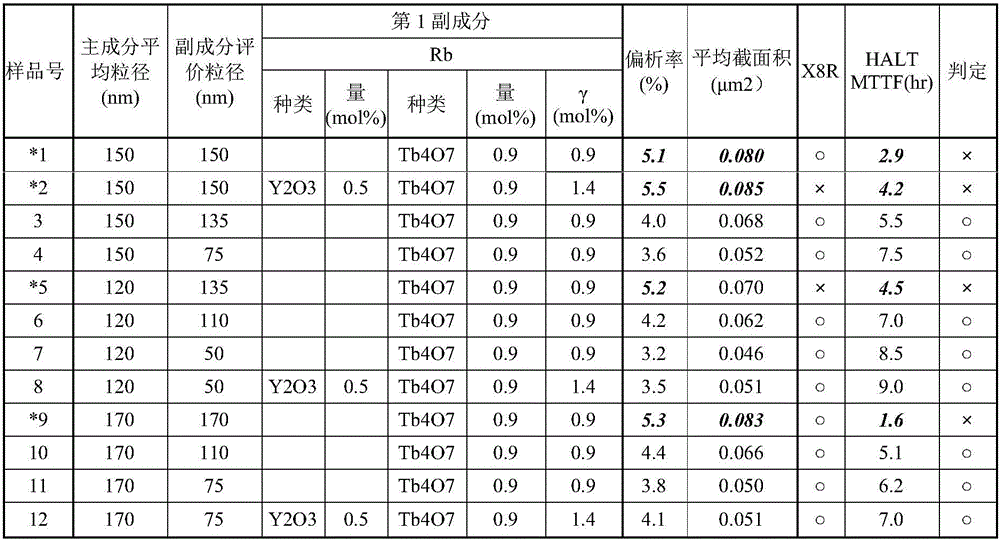

[0124] As the raw material powder of barium titanate as the main component, Ba with a specific average particle diameter (120 to 170 nm) shown in Table 1 below was prepared. u Ti v o 3 Powder (u / v=1.004).

[0125] Prepare Eu 2 o 3 Powder, prepare Yb as raw material powder of Ra oxide 2 o 3 Powder, prepare Tb as raw material powder of oxides of Rb 2 o 3.5 Powder and Y 2 o 3 powder.

[0126] SiO was prepared as the raw material powder of Si oxide as the second subcomponent 2 powder.

[0127] Furthermore, as the raw material powder of the oxide of Ba, prepare BaCO 3 powder. Prepare MnCO as raw material powder of Mn oxide 3 powder. As a raw material powder of V oxide, prepare V 2 o 5 powder. MgO powder was prepared as a raw material powder of an oxide of Mg.

[0128] In addition, the raw material powders of all the above-mentioned subcomponents were preliminarily pulverized so that the average particle diameters of all the above-mentioned subcomponents were adju...

Embodiment 2

[0165] In addition to barium titanate (Ba u Ti v o 3 (u / v=1.004)) was set to 150 nm in average particle size, and the types of oxides of rare earth Ra and Rb were set to the values shown in Table 2, and the others were the same as sample No. 8 of Example 1. Multilayer ceramic capacitor samples of sample numbers 21 to 27 were produced, and the same characteristic evaluation as in Example 1 was performed. The results are shown in Table 2.

[0166] [Table 2]

[0167]

[0168] According to Table 2, even if the types of rare earth Ra and Rb oxides are changed as in sample numbers 21 to 27, the segregation rate is 5.0% or less, and the average cross-sectional area of segregated particles is 0.075 μm 2 In the following cases, the capacity temperature characteristics and the high-temperature load life were all good.

Embodiment 3

[0170] A multilayer ceramic capacitor sample of sample number 31 was produced in the same manner as sample number 4 of Example 1 except for the firing conditions, and the same characteristic evaluation as in Example 1 was performed. The firing conditions of Sample No. 31 were such that the temperature increase rate was set to 2000° C. / hour, and the holding time was set to 0.2 hours. The results are shown in Sample No. 31 in Table 3.

[0171] In addition, the preparation of the dielectric material raw material was carried out by the method shown below. Except for the preparation of the dielectric material raw material, other samples No. 32 and 33 were produced in the same manner as the sample No. 4 of Example 1, and the same procedure as in Example 1 was carried out. characteristic evaluation.

[0172] For the preparation of the dielectric raw material of sample No. 32, with respect to BaTiO as the main component 3 , only the oxide of Si and the oxide of Ra, that is, Yb 2 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com