Myrcene production system

A production system, myrcene technology, applied in distillation separation, organic chemistry, organic chemical methods, etc., can solve the problems of high energy consumption, low output, high production cost, etc., and achieve the goal of improving fractionation effect, reducing cost, and reducing energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

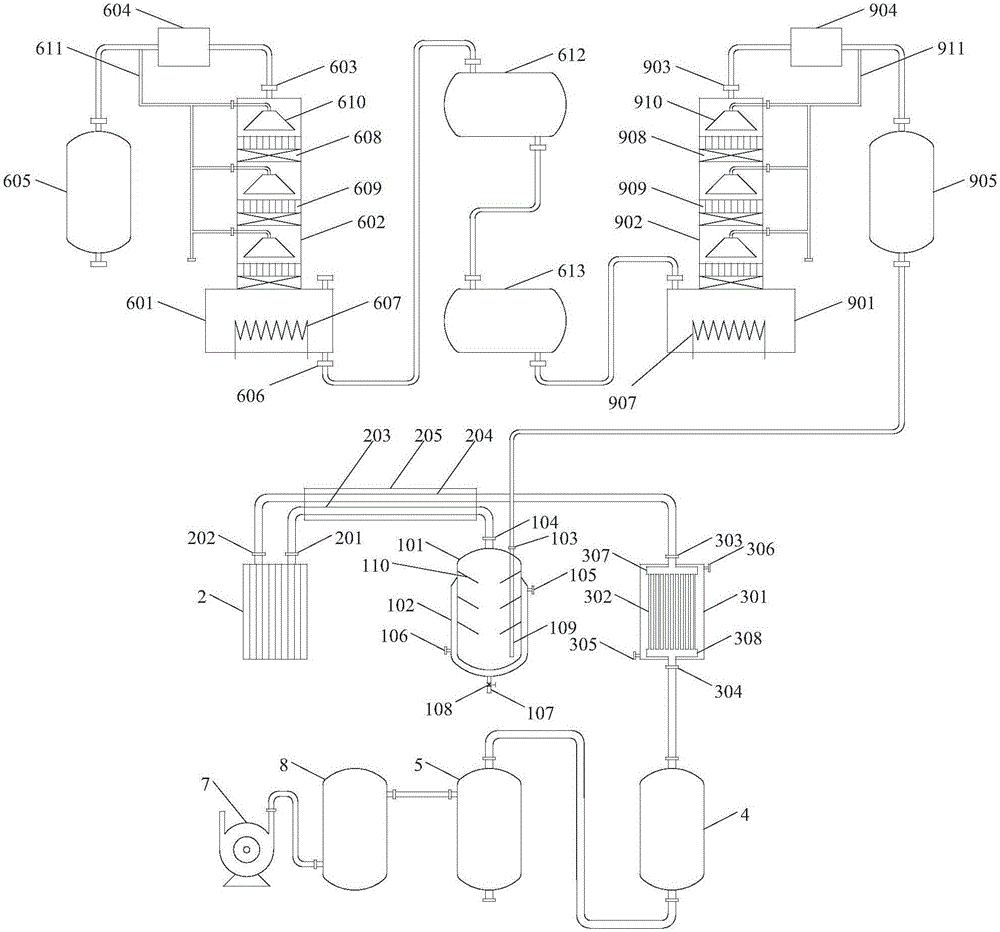

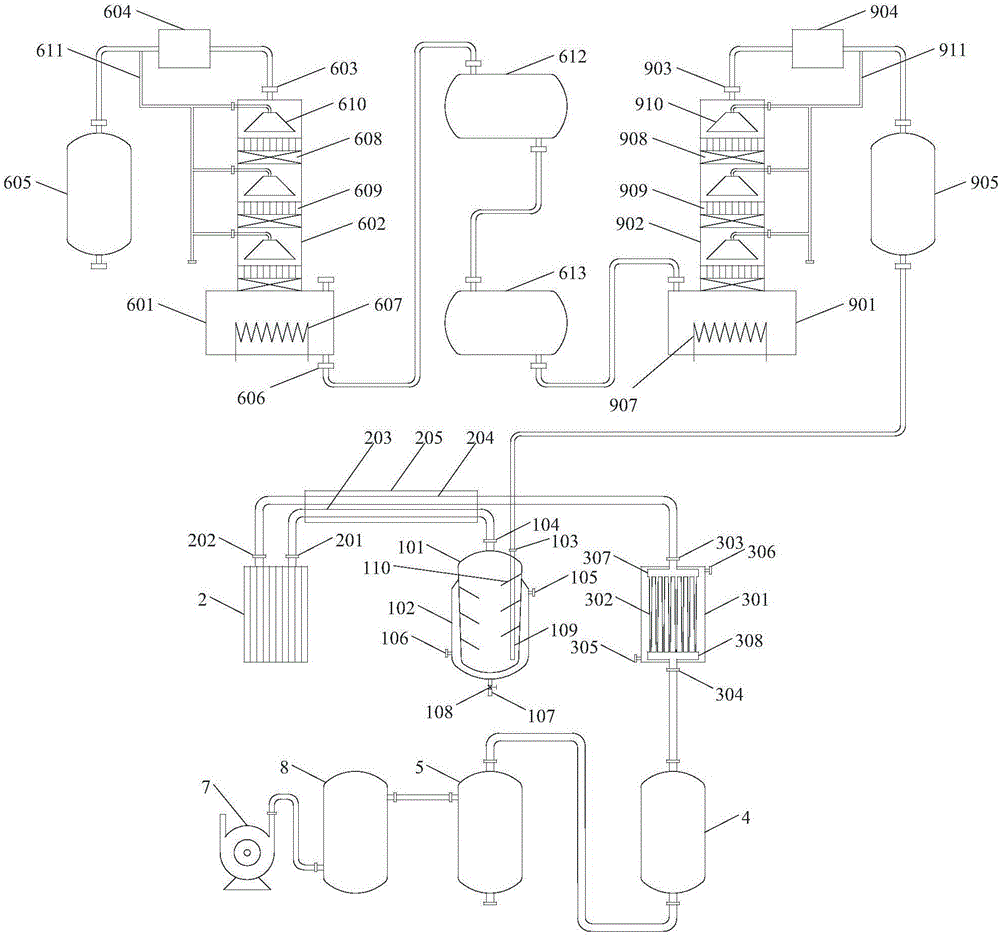

[0024] refer to figure 1 The production system of a kind of myrcene shown comprises successively connected α-pinene fractionation tower 6, β-pinene fractionation tower 9, preheater 1, cracker 2, cooler 3, vacuum buffer tank 4, vacuum Receiving tank 5, vacuum gas storage tank 8 and vacuum pump 7, the feed port of described β-pinene fractionation tower 9 is connected with the β-pinene mother liquor outlet of described α-pinene fractionation tower 6, and described pre- The feed port 103 of the heater 1 is connected with the β-pinene discharge port 904 of the β-pinene fractionation tower 9, and the feed port 104 of the preheater 1 is connected with the feed port of the cracker 2 201 is connected through a first pipeline 203, the outlet 202 of the cracker 2 is connected with the feed inlet 303 of the cooler 3 through a second pipeline 204, and the first pipeline 203 and the second pipeline 204 are jointly wrapped with Insulation layer 205.

[0025]The α-pinene fractionation tower...

Embodiment 2

[0029] refer to figure 1 The production system of a kind of myrcene shown comprises successively connected α-pinene fractionation tower 6, β-pinene fractionation tower 9, preheater 1, cracker 2, cooler 3, vacuum buffer tank 4, vacuum Receiving tank 5, vacuum gas storage tank 8 and vacuum pump 7, the feed port of described β-pinene fractionation tower 9 is connected with the β-pinene mother liquor outlet of described α-pinene fractionation tower 6, and described pre- The feed port 103 of the heater 1 is connected with the β-pinene discharge port 904 of the α-pinene fractionation tower 9, and the feed port 104 of the preheater 1 is connected with the feed port of the cracker 2 201 is connected through the first pipeline 203, the outlet 202 of the cracker 2 is connected with the feed inlet 303 of the cooler 3 through the second pipeline 204, and the first pipeline 203 and the second pipeline 204 are jointly wrapped with Insulation layer 205.

[0030] The α-pinene fractionation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com