Synthetic method for preparing thiophenecarboxaldehyde

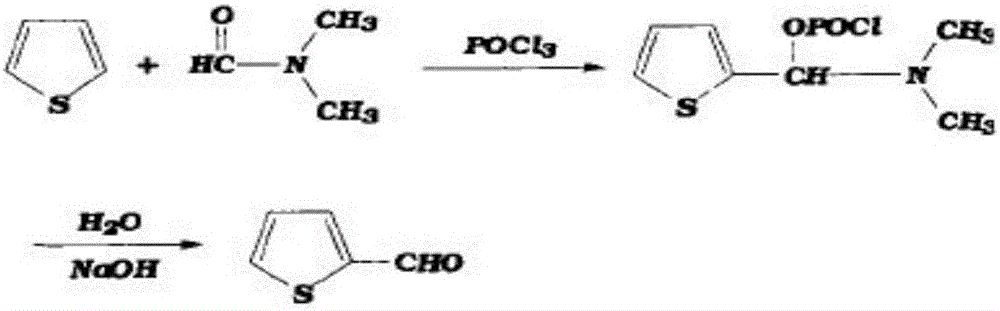

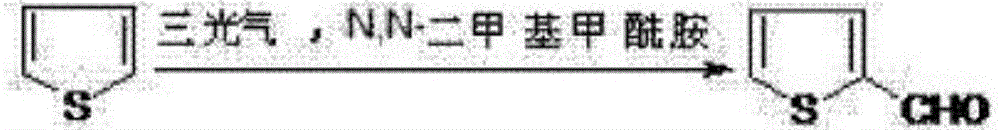

A technology of thiophene formaldehyde and synthesis method, which is applied in the direction of organic chemistry and the like, can solve the problems of low yield of thiophene formaldehyde, leakage of phosgene, insufficient purity, etc., and achieves the advantages of improving yield and purity, ensuring airtightness and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of synthetic method for preparing thiophene formaldehyde mainly comprises the following steps:

[0021] (1) Add 0.2mol DMF and 0.3mol solvent dichloroethane CH to the synthesizer 2 Cl 2 Finally, feed 0.1mol phosgene into the synthesizer through a feed pipe with a safety valve at the port and a seamless steel casing with an alarm on the side of the safety valve, and control the reaction temperature to 0°C. Generate the Vilsmeier-Haack reagent after the reaction;

[0022] (2) Add 0.5 mol of raw material thiophene dropwise to the Vilsmeier-Haack reagent at normal temperature, and control the reaction temperature to be 60° C.;

[0023] (3) After the reaction, first cool the product to room temperature, add process water to hydrolyze to obtain crude thiophene formaldehyde, after standing for stratification, extract the water layer with benzene and rectify to obtain pure thiophene formaldehyde, the tail gas after the reaction Can be absorbed by lye.

[0024] The yi...

Embodiment 2

[0026] A kind of synthetic method for preparing thiophene formaldehyde, its synthetic method comprises the following steps:

[0027] (1) Add 0.2mol DMF and 0.3mol solvent dichloroethane CH to the synthesizer 2 Cl 2 Finally, pass 0.1mol phosgene into the synthesizer through a seamless steel casing with a safety valve at the port and an alarm on the side of the safety valve, and control the reaction temperature to 0°C. Generate Vilsmeier-Haack reagent;

[0028] (2) Add 0.5 mol of raw material thiophene dropwise to the Vilsmeier-Haack reagent at normal temperature, and control the reaction temperature to be 30° C.;

[0029] (3) After reacting for a period of time, first cool the product to room temperature, add process water to hydrolyze to obtain crude thiophene formaldehyde, after standing for stratification, extract the water layer with benzene and rectify to obtain pure product thiophene formaldehyde, after the reaction ends Exhaust gas can be absorbed by lye.

[0030] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com