Hydroxyl resin for organic silicon-coated material and preparation method of hydroxyl resin

A technology of coating material and hydroxyl resin, which is applied in the field of hydroxyl resin and its preparation, can solve the problems of limiting the application and development of silicone coating materials, poor tear resistance, and uneven performance, so as to avoid gel phenomenon and cure Short, easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

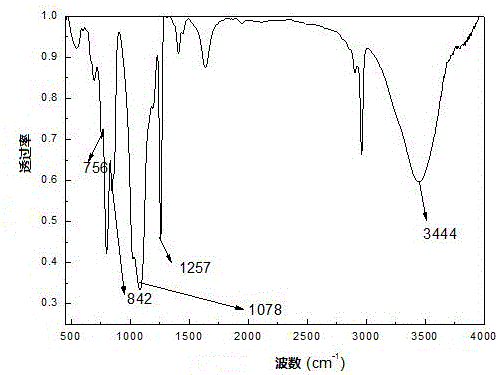

Image

Examples

Embodiment 1

[0030] A hydroxyl resin for silicone coating materials:

[0031] (1) Mix 0.15kg hydrochloric acid, 0.9kg ethanol and 1.1kg water uniformly to obtain mixed material 1; mix 3kg tetraethyl orthosilicate-40 and 2kg hexamethyldisiloxane uniformly to obtain mixed material 2;

[0032] (2) Add the mixed material 1 into the reaction kettle, mix and stir evenly; then add the mixed material 2 into the reaction kettle, and mix and react for 40 minutes;

[0033] (3) Add 1.45kg of hexamethyldisiloxane to the reaction kettle, heat it up to 50°C, and then conduct a steady-temperature reflux reaction for 6 hours;

[0034] (4) After the stable temperature reflux reaction in step (3) is completed, let stand to separate layers, separate the lower oil layer, then add sodium carbonate aqueous solution to the oil layer to adjust the pH value to pH > 7, let stand to separate layers, and separate the lower layer Oil layer, then wash the oil layer with water, wash to oil layer pH=7, obtain resin liqui...

Embodiment 2

[0040] A hydroxyl resin for silicone coating materials:

[0041] (1) Mix 0.1kg hydrochloric acid, 1kg ethanol and 1kg water uniformly to obtain mixed material 1; mix 2.5kg tetraethyl orthosilicate-40 and 2.5kg hexamethyldisiloxane uniformly to obtain mixed material 2;

[0042] (2) Add the mixed material 1 into the reaction kettle, mix and stir evenly; then add the mixed material 2 into the reaction kettle, and mix and react for 40 minutes;

[0043] (3) Add 1.5kg of hexamethyldisiloxane to the reaction kettle, heat it up to 70°C, and then conduct a steady-temperature reflux reaction for 8 hours;

[0044] (4) After the stable temperature reflux reaction in step (3) is completed, let stand to separate layers, separate the lower oil layer, then add sodium carbonate aqueous solution to the oil layer to adjust the pH value to pH > 7, let stand to separate layers, and separate the lower layer Oil layer, then wash the oil layer with water, wash to oil layer pH=7, obtain resin liquid;...

Embodiment 3

[0050] A hydroxyl resin for silicone coating materials:

[0051] (1) Mix 0.5kg hydrochloric acid, 2kg ethanol and 3kg water uniformly to obtain mixed material 1; mix 5kg tetraethyl orthosilicate-40 and 4kg hexamethyldisiloxane uniformly to obtain mixed material 2;

[0052] (2) Add the mixed material 1 into the reaction kettle, mix and stir evenly; then add the mixed material 2 into the reaction kettle, and mix and react for 30 minutes;

[0053] (3) Add 2kg of hexamethyldisiloxane to the reaction kettle, heat it up to 60°C, and then conduct a steady-temperature reflux reaction for 6 hours;

[0054] (4) After the stable temperature reflux reaction in step (3) is completed, let stand to separate layers, separate the lower oil layer, then add sodium carbonate aqueous solution to the oil layer to adjust the pH value to pH > 7, let stand to separate layers, and separate the lower layer Oil layer, then wash the oil layer with water, wash to oil layer pH=7, obtain resin liquid;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com