Die casting method of dry aluminium alloy double-clutch valve body

A double-clutch, aluminum alloy technology, applied in the field of die-casting, can solve the problems of high cost and high scrap rate, achieve the effects of fine purity, improve production efficiency, and reduce internal slag inclusions and pore defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

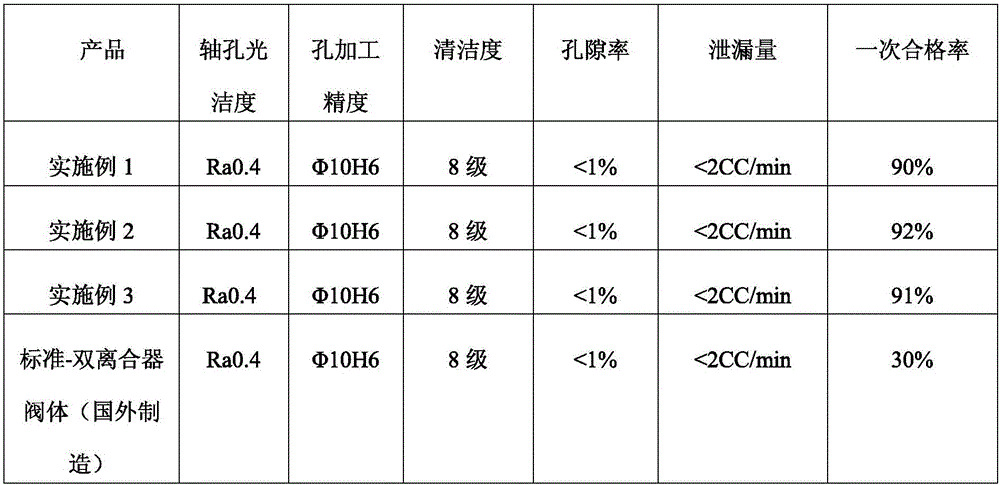

Examples

Embodiment 1

[0043] A die-casting method for an aluminum alloy dry double clutch valve body, comprising the following steps:

[0044] (1) The weight ratio is 8% Si, 0.05% Mg, 1.0% Fe, 2.0% Cu, 0.25% Mn, 0.25% Ni, 0.6% Zn, 0.15% Pb, 0.1% Sn; 0.1% Ti, 0.05% Cr, and the rest being Al are added to the die-casting melting furnace;

[0045] (2) The melting temperature of the die-casting melting furnace is set to 710°C, and the die-casting melting furnace starts to heat up, and when the temperature of the die-casting melting furnace rises to 710°C, add Huasheng block non-toxic refining with an amount of 0.2% of the total weight of the material Modifiers for refining;

[0046] (3) While adding the refining modificator in step (2), use a degasser to carry out a degassing operation with 99.99% argon for 3 minutes, take a sample, and use a spectral analysis device to detect the composition of the sample, if the composition is qualified Stand still for 8 minutes to prepare for die casting;

[0047]...

Embodiment 2

[0053] A die-casting method for an aluminum alloy dry double clutch valve body, comprising the following steps:

[0054] (1) 11% of Si, 0.55% of Mg, 1.5% of Fe, 4.0% of Cu, 0.55% of Mn, 0.55% of Ni, 1.2% of Zn, 0.35% of Pb, 0.25% of Sn; 0.25% Ti, 0.15% Cr, and the rest being Al are added to the die-casting melting furnace;

[0055] (2) The melting temperature of the die-casting melting furnace is set to 740°C, and the die-casting melting furnace starts to heat up, and when the temperature of the die-casting melting furnace rises to 730°C, add Huasheng block non-toxic refining with an amount of 0.6% of the total weight of the material Modifiers for refining;

[0056] (3) While adding the refining modificator in step (2), use a degasser to carry out a degassing operation with 99.99% argon for 15 minutes, take a sample, and use a spectral analysis device to detect the composition of the sample, if the composition is qualified Stand still for 15 minutes to prepare for die castin...

Embodiment 3

[0063] A die-casting method for an aluminum alloy dry double clutch valve body, comprising the following steps:

[0064] (1) The weight ratio is 10% Si, 0.25% Mg, 1.0% Fe, 1.5% Cu, 0.50% Mn, 0.50% Ni, 0.8% Zn, 0.25% Pb, 0.15% Sn; 0.15% Ti, 0.1% Cr, and the rest being Al are added to the die-casting melting furnace;

[0065] (2) The melting temperature of the die-casting melting furnace is set to 720°C, and the die-casting melting furnace starts to heat up, and when the temperature of the die-casting melting furnace rises to 710°C, add Huasheng block non-toxic refining with an amount of 0.3% of the total weight of the material Modifiers for refining;

[0066] (3) While adding the refining modificator in step (2), use a degasser to carry out a degassing operation with 99.99% argon for 20 minutes, take a sample, and use a spectral analysis device to detect the composition of the sample, if the composition is qualified Stand still for 10 minutes to prepare for die casting;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com