Sound insulation wall for studio

A sound insulation wall and broadcasting room technology, applied in the direction of sound insulation, wall, adhesive type, etc., can solve the problems of poor contact between adjacent parts, sound leakage, and loose fixation, etc., to achieve good sound insulation, improve wettability, The effect of shortening the surface dry time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

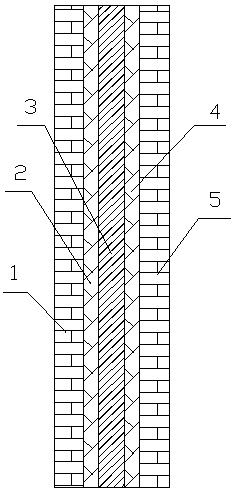

[0025] refer to figure 1 , this embodiment provides a sound insulation wall for a studio, comprising a first wall 1 and a second wall 5, a sound insulation module is arranged between the first wall 1 and the second wall 5, and the sound insulation The module includes a first sound-absorbing cotton layer 2, a second sound-absorbing cotton layer 4 and a damping plate 3 arranged between the first sound-absorbing cotton layer 2 and the second sound-absorbing cotton layer 4, the first sound-absorbing cotton layer 2 and the second sound-absorbing cotton layer Both sides of the second sound-absorbing cotton layer 4 are coated with adhesive, and the sides of the first wall 1 and the second wall 5 away from the sound-insulating module are sprayed with paint.

[0026] Among them, in order to enhance the supporting and fixing effects of the first sound-absorbing cotton layer 2 and the second sound-absorbing cotton layer 4, keels, preferably light steel keels, are arranged in the first so...

Embodiment 2

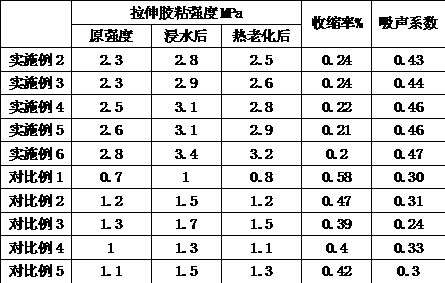

[0029] The provision of a sound insulation wall for a broadcasting room in this embodiment is an improvement on the basis of Example 1, the difference is that the adhesive is prepared from the following components by weight: 25 parts of polyacrylamide, 15 parts of sodium silicate 5 parts, 5 parts of filler, 6 parts of additive, 3 parts of Terotex-218 soundproof agent, 2.5 parts of surfactant, 23 parts of acetone, 40 parts of water.

[0030] The filler is a mixture of kaolin, silicon carbide and titanium dioxide, the weight ratio of kaolin: silicon carbide: titanium dioxide is 1:2:4, and the particle size is 200 mesh.

[0031] The auxiliary agent is a mixture of sodium chromate, nonylphenol polyoxyethylene ether and p-toluenesulfonic acid, and the weight ratio of sodium chromate: nonylphenol polyoxyethylene ether: p-toluenesulfonic acid is 1:5:3.5.

[0032] The surfactant is dioctyl sodium sulfosuccinate.

Embodiment 3

[0034] The provision of a sound insulation wall for a broadcasting room in this embodiment is an improvement on the basis of Embodiment 1, the difference is that: the adhesive is prepared from the following components by weight: 27 parts of polyacrylamide, sodium silicate 18 parts, 6 parts of filler, 6.5 parts of additives, 4 parts of Terotex-218 soundproof agent, 3 parts of surfactant, 25 parts of acetone, 42 parts of water.

[0035] The filler is a mixture of kaolin, silicon carbide and titanium dioxide, the weight ratio of kaolin: silicon carbide: titanium dioxide is 1:3:4, and the particle size is 250 mesh.

[0036] The auxiliary agent is a mixture of sodium chromate, nonylphenol polyoxyethylene ether and p-toluenesulfonic acid, and the weight ratio of sodium chromate: nonylphenol polyoxyethylene ether: p-toluenesulfonic acid is 1:5:4.

[0037] The surfactant is sodium laurylalanine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com