Wear-resistant and corrosion-resistant material with Ni-P-Ce-B4C (Cu) composite coating and preparation technology of material

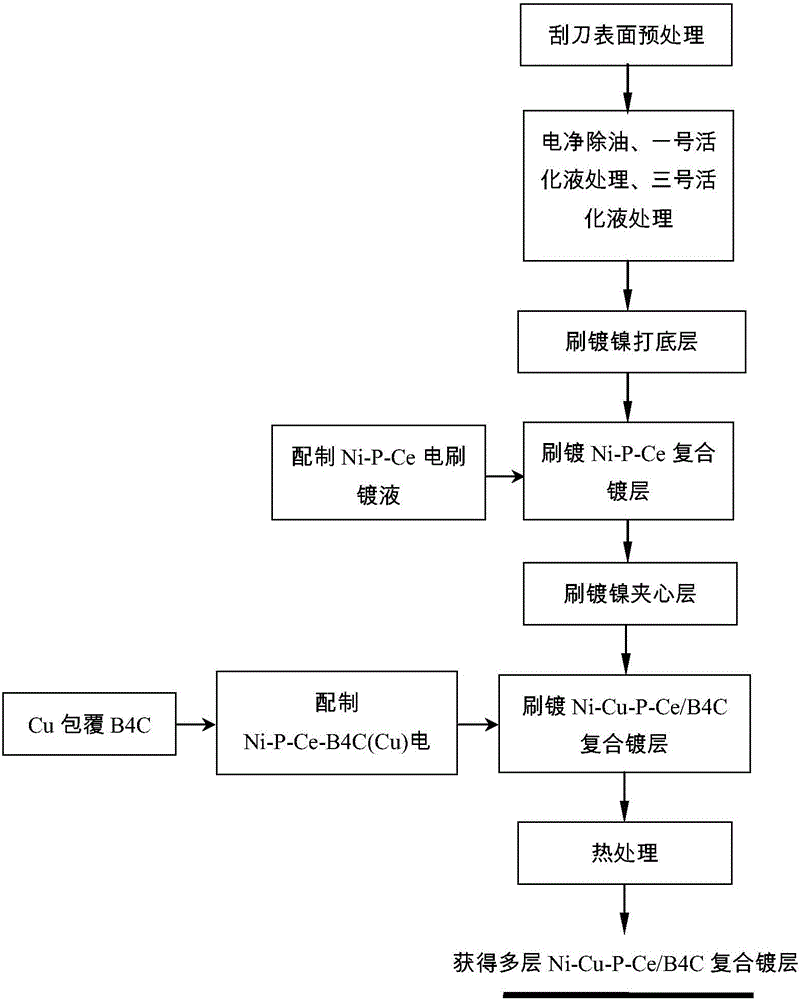

A ni-p-ce-b4c, corrosion-resistant material technology, applied in the field of wear-resistant and anti-corrosion coating and its preparation, can solve the problem that the composition ratio is difficult to grasp, the wear and corrosion resistance performance is poor, and the wear and corrosion resistance cannot be satisfied. and other problems, to achieve the effect of shortening the capture time, improving corrosion resistance and bonding strength, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Dissolve 240g of nickel sulfate, 15g of sodium hypophosphite, 20g of citric acid, and 20g of citric acid tris in deionized water according to the composition and concentration requirements of plating solution A-1 and the volume of plating solution A-1 required in the actual production process. Sodium, 18g of sodium sulfate, 0.1g of sodium lauryl sulfate, 25g of cerium nitrate, and 20ml of glacial acetic acid were prepared; then the obtained citric acid solution, trisodium citrate solution and glacial acetic acid were stirred for 6 minutes to obtain a complexing agent solution; Then mix the complexing agent solution and nickel sulfate solution evenly for 10 minutes to obtain solution A; then add cerium nitrate and sodium sulfate solution to solution A and stir for 5 minutes to obtain solution B. Then, under rapid stirring, the sodium hypophosphite solution was slowly added to solution B, and stirred for 20 minutes. Finally, the pH of the solution was adjusted to 3.0 with...

Embodiment 2

[0065] Dissolve 260g of nickel sulfate, 20g of sodium hypophosphite, 20g of citric acid, and 20g of citric acid tris in deionized water according to the composition and concentration requirements of plating solution A-1 and the volume of plating solution A-1 required in the actual production process. Sodium, 18g of sodium sulfate, 0.1g of sodium lauryl sulfate, 35g of cerium nitrate, and 20ml of glacial acetic acid were prepared; then the obtained citric acid solution, trisodium citrate solution and glacial acetic acid were stirred for 6 minutes to obtain a complexing agent solution; Then mix the complexing agent solution and nickel sulfate solution evenly for 10 minutes to obtain solution A; then add cerium nitrate and sodium sulfate solution to solution A and stir for 5 minutes to obtain solution B. Then, under rapid stirring, the sodium hypophosphite solution was slowly added to solution B, and stirred for 20 minutes. Finally, the pH of the solution was adjusted to 4.0 with...

Embodiment 3

[0073]Dissolve 280g nickel sulfate, 25g sodium hypophosphite, 20g citric acid, 20g trisodium citrate, 18g of sodium sulfate, 0.1g of sodium lauryl sulfate, 45g of cerium nitrate, and 20ml of glacial acetic acid; then the obtained citric acid solution, trisodium citrate solution and glacial acetic acid were stirred for 6 minutes to obtain a complexing agent solution; The complexing agent solution and nickel sulfate solution were mixed evenly for 10 minutes to obtain solution A; then cerium nitrate and sodium sulfate solutions were added to solution A and stirred for 5 minutes to obtain solution B. Then, under rapid stirring, the sodium hypophosphite solution was slowly added to solution B, and stirred for 20 minutes. Finally, the pH of the solution was adjusted to 5.0 with a pH regulator, and the volume was adjusted to 1 L. The regulator is 15% dilute ammonia water, and the plating solution A-1 is prepared at this time.

[0074] After the B4C powder was roughened with 10% NH4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com