Ammonia-escaping-rate online obtaining method for desulfurization and denitrification control

A technology of ammonia slip rate and acquisition method, which is applied in the field of online acquisition of ammonia slip rate at the outlet of SCR reactor in the denitrification system of large coal-fired units, and can solve the problem of reducing the measurement accuracy of ammonia slip rate, the influence of sampling accuracy, and the maintenance of gas system Large volume and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

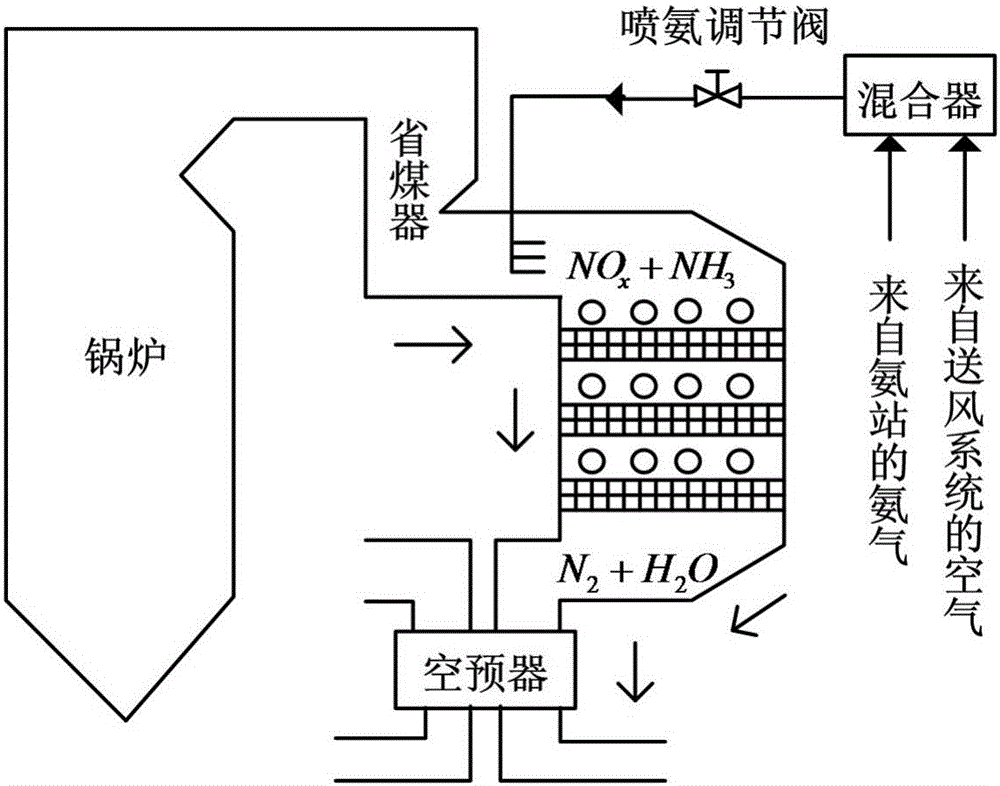

[0039] The process flow of SCR denitrification system is as follows: figure 1 As shown, the SCR adopts the low-temperature reaction method. The ammonia gas from the ammonia station is mixed with the dilution air from the air supply system, sprayed out from the nozzle of the ammonia injection grid, and fully mixed with the flue gas from the economizer outlet, and then flows through the The catalyst, under the action of the catalyst, utilizes the selectivity of the reducing agent ammonia to preferentially react with NOx, reducing it to nitrogen and water, so as to achieve the purpose of denitrification. Ammonia is used as a reducing agent. During the reaction process, some unreacted ammonia will enter the downstream equipment along with the flue gas, forming ammonia escape.

[0040] As an important indicator of whether the amount of ammonia injection is excess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com