Preparation method and application of ionic liquid

A technology of ionic liquids and ions, which is applied in the preparation of ionic liquids and its application fields, can solve the problems of poor stability of antistatic agents, poor antistatic durability, and no long-term effect, and achieve less impurity ion content, which is conducive to industrialization, The effect of the simplicity of the preparation protocol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

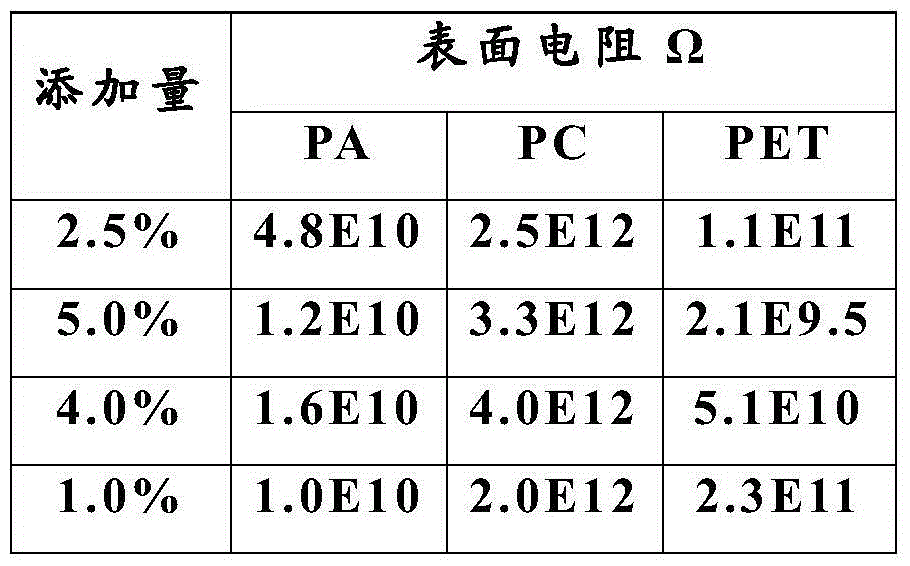

Image

Examples

Embodiment 1

[0029] Example 1: 1-ethyl-3-methylimidazole bis-trifluoromethanesulfonimide salt (EMI TFSI)

[0030] Step 1: Take 287.1g of lithium bistrifluoromethanesulfonylimide (LiTFSI) and completely dissolve it in water to form an aqueous solution with a concentration of 50% by mass;

[0031] Step 2: Take 191.1g of 1-ethyl-3-methylimidazole bromide (EMIBr) and completely dissolve it in water to form an aqueous solution with a concentration of 50% by mass;

[0032] Step 3: Fully mix and react the aqueous solution product obtained in Step 1 and Step 2, and separate the liquid to obtain the crude product;

[0033] Step 4: The crude product obtained in Step 3 is washed twice with water, stirred, emulsified, heated to 60°C to break the emulsion, and then separated to obtain a high-purity product;

[0034] Step 5: Vacuum-dry the high-purity product obtained in Step 4 for 8 hours at 100°C to obtain 383.5g of colorless liquid EMI·TFSI product (melting point about -15°C), purity 99.95%, moistur...

Embodiment 2

[0035] Example 2: Tri-n-butylmethylammonium bis(trifluoromethanesulfonyl)imide salt (TBMA TFSI)

[0036] Step 1. Take 287g LiTFSI and completely dissolve it in water to form an aqueous solution with a concentration of 50% by mass;

[0037] Step 2, get 236g tributylmethylammonium chloride (TBMACl) and be completely dissolved in water and be configured into the aqueous solution that mass percent concentration is 50%;

[0038] Step 3, the aqueous solution product obtained in step 1 and step 2 is fully mixed and reacted, and the liquid separation is obtained to obtain the crude product;

[0039] Step 4: The crude product obtained in Step 3 is washed with water for 3 times, and the emulsion is broken by stirring, emulsifying, heating up to 70°C, and the high-purity product is obtained after liquid separation;

[0040] Step 5: Vacuum dry the high-purity product obtained in Step 4 at 100° C. for 10 hours to obtain 462 g of a colorless liquid TBMA·TFSI product (melting point about 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com