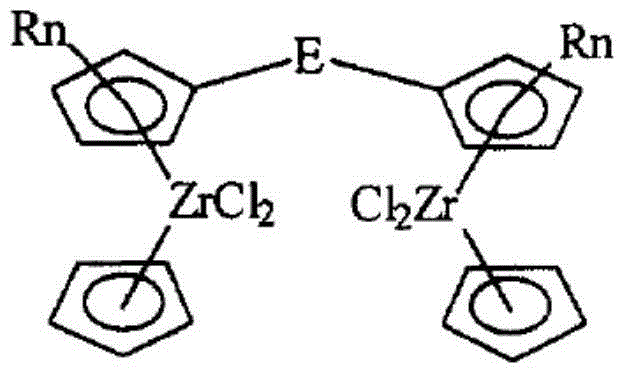

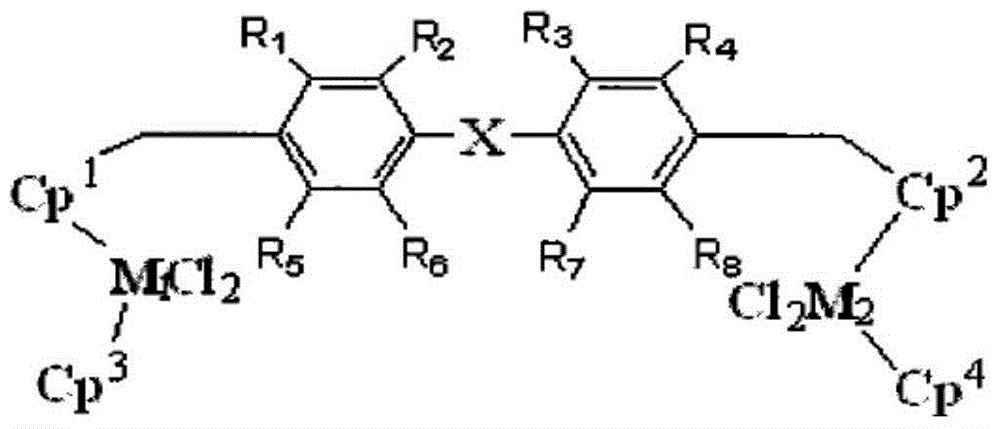

Bridged metallocene compound catalyst, and preparation method and application thereof

A metallocene compound and catalyst technology, applied in metallocene, chemical instruments and methods, organic chemistry, etc., can solve the problems of small steric hindrance of substituent groups, fast chain transfer, insufficient rigidity, etc., and achieves wide application prospects, good Effects of catalytic activity, good mechanical properties and processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Synthesis of compound a

[0040] Add 0.25mol 3,5-dichlorobenzonitrile and 100mL dry diethyl ether to a 500mL three-neck flask, then add 3.5g metallic lithium at -20°C and react for 20 hours, then add 0.5mol monomethyltrichlorosilane in an ice-water bath After reacting for 6 hours, add 100 mL of distilled water to wash, remove the organic phase with a pear-shaped separatory funnel, wash the water phase with 50 mL of ether three times, combine the organic phases, and wash with anhydrous MgSO 4 Dry, filter, remove the solvent in vacuo, and then recrystallize from ethanol to obtain 22.73 g of white solid, yield 46%.

[0041] Dissolve the above compound in 100 mL of dry tetrahydrofuran, slowly add 0.48 mol cyclopentadiene sodium dropwise at -30°C for 12 hours, remove the solvent in vacuo, and extract the residual solid with 50 mL of ether three times, then place it in an ice-water bath Slowly add 192mL of 2.5M n-butyllithium hexane solution dropwise, then stir at room t...

Embodiment 2

[0047] (1) Synthesis of compound b

[0048] Add 0.12mol 3,5-dichlorobenzonitrile and 80mL dry diethyl ether to a 500mL three-neck flask, then add 1.7g metallic lithium at -20°C and react for 20 hours, then add 0.25mol monomethyltrichlorosilane in an ice-water bath After reacting for 6 hours, add 80 mL of distilled water to wash, remove the organic phase with a pear-shaped separatory funnel, wash the water phase with 30 mL of ether three times, combine the organic phases, and wash with anhydrous MgSO 4 Dry, filter, remove the solvent in vacuo, and then recrystallize from ethanol to obtain 11.53 g of white solid, yield 46%.

[0049] Dissolve the above compound in 100 mL of dry tetrahydrofuran, slowly add 0.24 mol of indenyllithium dropwise at -30°C for 12 hours, remove the solvent in vacuo, extract the residual solid with 50 mL of ether three times, and then slowly drop it in an ice-water bath Add 81mL of 2.5M n-butyllithium hexane solution, then stir at room temperature for 12...

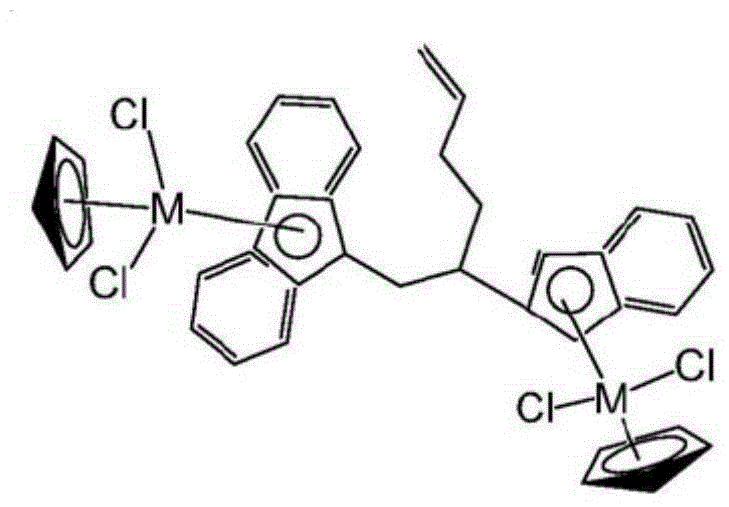

Embodiment 3

[0055] (1) Synthesis of compound c

[0056] Add 0.06mol 3,5-dichlorobenzonitrile and 60mL dry diethyl ether to a 500mL three-necked flask, then add 0.84g metallic lithium at -20°C and react for 20 hours, then add 0.12mol phenyltrichlorosilane in an ice-water bath After reacting for 6 hours, add 60 mL of distilled water to wash, remove the organic phase with a pear-shaped separatory funnel, wash the water phase with 30 mL of ether three times, combine the organic phases, and wash with anhydrous MgSO 4 Dry, filter, remove the solvent in vacuo, and then recrystallize from ethanol to obtain 12.15 g of white solid, yield 44%.

[0057] Dissolve the above compound in 100 mL of dry tetrahydrofuran, slowly add 0.12 mol of sodium cyclocene at -30°C and react for 12 hours, remove the solvent in vacuo, extract the residual solid with 50 ethyl ether three times, and then slowly add 40mL of 2.5M n-butyllithium hexane solution, then stirred at room temperature for 12 hours, filtered, and va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com