A plugging agent, drilling fluid containing the plugging agent, and preparation method and application thereof

A plugging agent and drilling fluid technology, which is applied in the field of drilling fluid and its preparation, can solve the problems of poor plugging effect, high density of plugging agent, and large damage to the reservoir, so as to achieve a small degree of damage, prevent the collapse of the reservoir, good blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

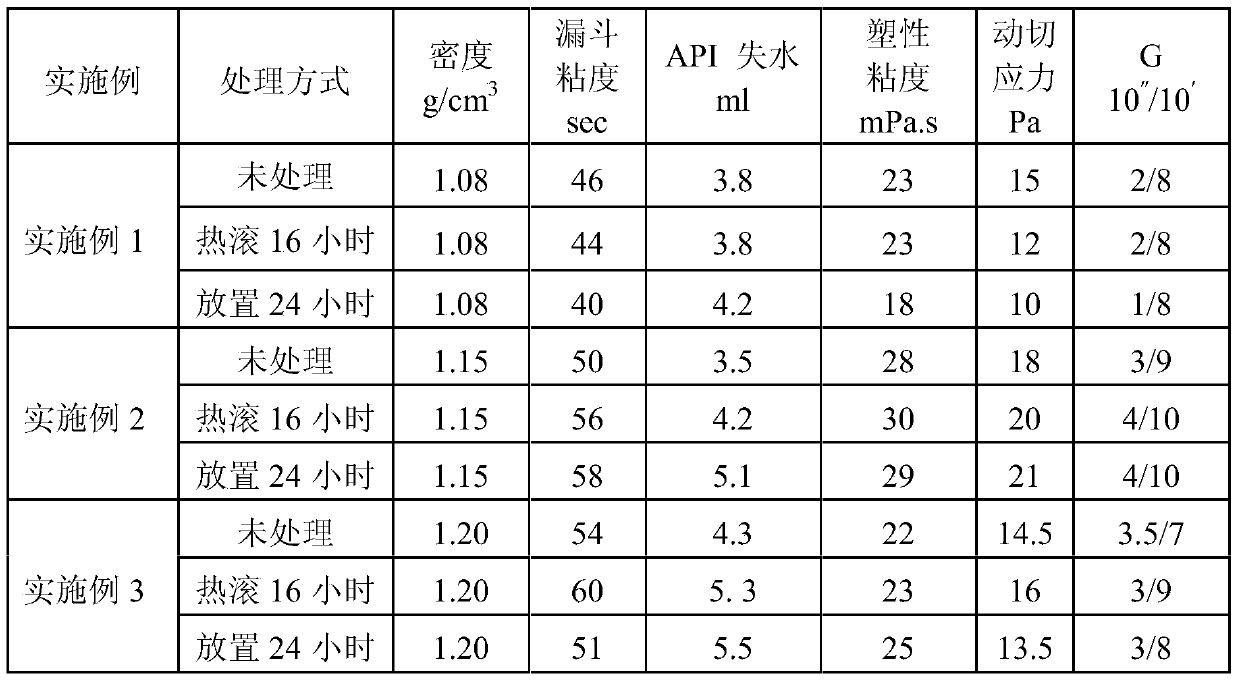

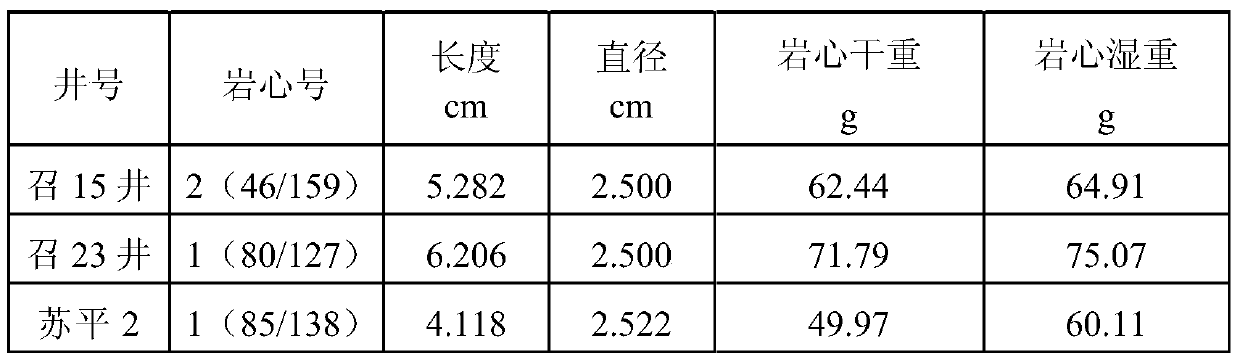

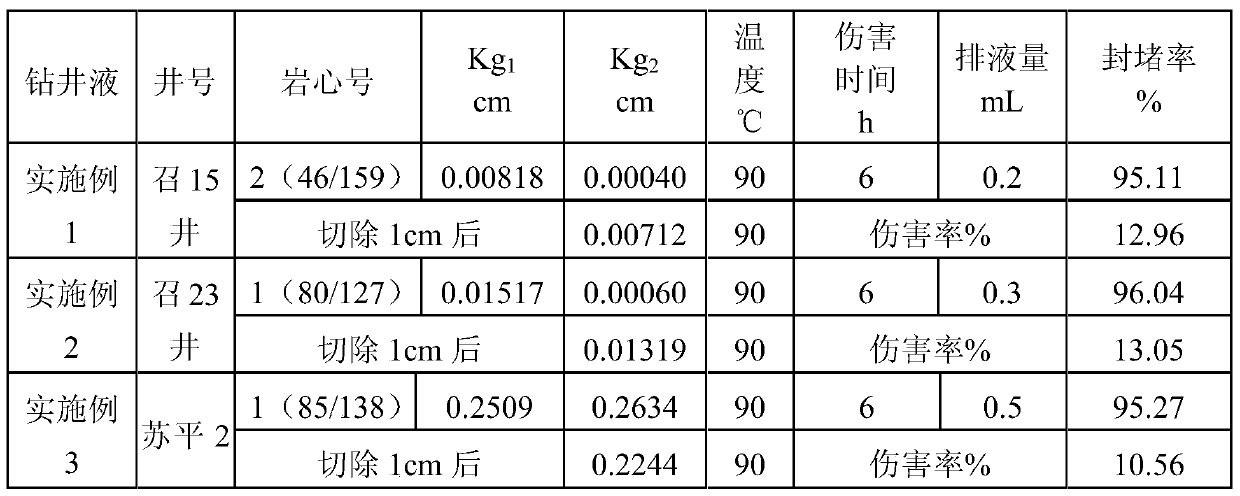

Examples

Embodiment 1

[0026] 1. Preparation of emulsified paraffin

[0027] Use the anionic surfactant OP-20 and the nonionic surfactant polyethylene glycol to emulsify the paraffin wax. The emulsification temperature is controlled at about 90°C, the emulsification time is about 2 hours, and the stirring rate is about 9000r / min. Emulsified paraffin wax with a diameter of ≤100 μm; the mass content of the components with a particle diameter of less than 1 μm in the emulsified paraffin wax is about 10%, the mass content of components with a particle diameter of 1-10 μm is about 45%, and the components with a particle diameter of more than 10 μm The mass content is about 45%.

[0028] 2. Preparation of acid-soluble mixed salt

[0029] After mixing 0.5 parts by weight of 500 mesh calcium carbonate, 1 weight part of 600 mesh calcium carbonate, 1.5 parts by weight of 800 mesh calcium carbonate and 2 parts by weight of 1200 mesh calcium carbonate, with 2 parts by weight of potassium formate and 3 parts by...

Embodiment 2

[0036] 1. Preparation of emulsified paraffin

[0037] Use anionic surfactant OP-25 and nonionic surfactant polyvinyl alcohol to emulsify paraffin wax. The emulsification temperature is controlled at about 95°C, the emulsification time is about 1.5 hours, and the stirring rate is about 10000r / min. Emulsified paraffin wax of ≤100 μm; the mass content of components with a particle size of less than 1 μm in the emulsified paraffin wax is about 10%, the mass content of components with a particle size of 1-10 μm is about 50%, and the mass content of components with a particle size of more than 10 μm The mass content is about 40%.

[0038] 2. Preparation of acid-soluble mixed salt

[0039] After mixing the 500 mesh calcium carbonate of 1.5 parts by weight, the 600 mesh calcium carbonate of 2 parts by weight, the 800 mesh calcium carbonate of 3 parts by weight and the 1200 mesh calcium carbonate of 3.5 parts by weight, with 3 weight parts of sodium formate and 5 parts by weight of P...

Embodiment 3

[0046] 1. Preparation of emulsified paraffin

[0047] Use the anionic surfactant OP-20 and the nonionic surfactant polyethylene glycol to emulsify the paraffin wax. The emulsification temperature is controlled at about 85°C, the emulsification time is about 2 hours, and the stirring rate is about 9500r / min. Emulsified paraffin wax with a diameter of ≤100 μm; the mass content of components with a particle diameter of less than 1 μm in the emulsified paraffin wax is about 10%, the mass content of components with a particle diameter of 1-10 μm is about 40%, and the component with a particle diameter of more than 10 μm The mass content is about 50%.

[0048] 2. Preparation of acid-soluble mixed salt

[0049] After mixing the 500 mesh calcium carbonate of 1.5 parts by weight, the 600 mesh calcium carbonate of 3 parts by weight, the 800 mesh calcium carbonate of 4.5 parts by weight and the 1200 mesh calcium carbonate of 6 parts by weight, with 3 weight parts of sodium formate and 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com