Method for producing palm kernel meal protein feed through solid state fermentation

A technology of palm kernel meal and solid state fermentation, which is applied in the molding or processing of animal feed, animal feed, animal feed, etc., to achieve the effect of simplifying the production process, simple process and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

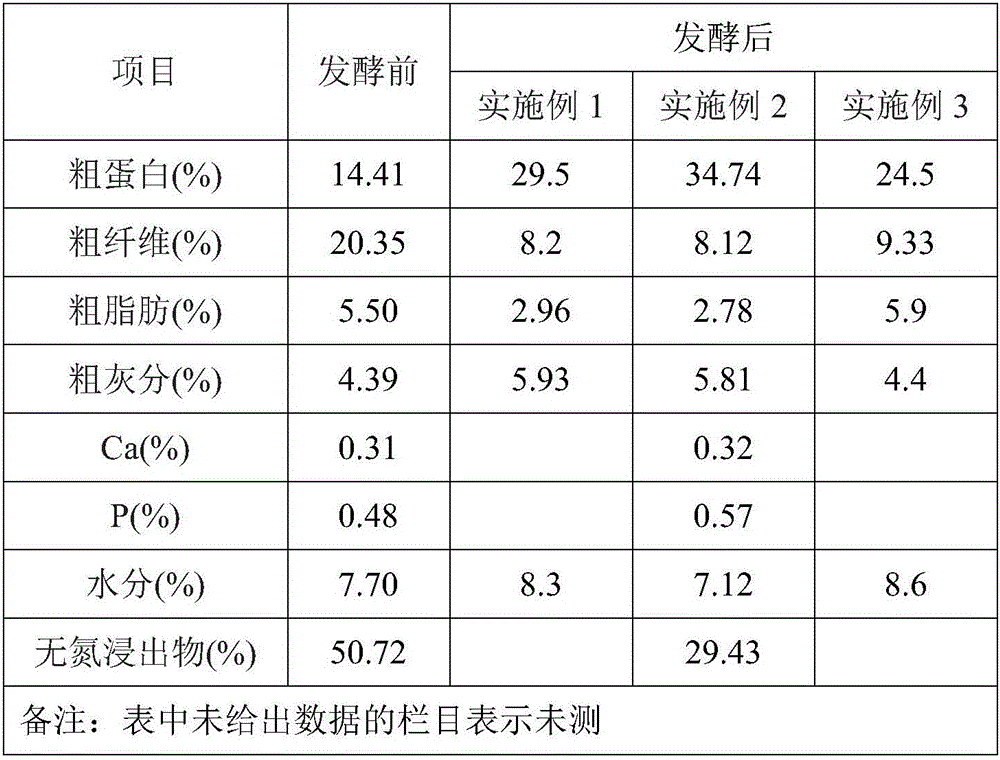

Embodiment 1

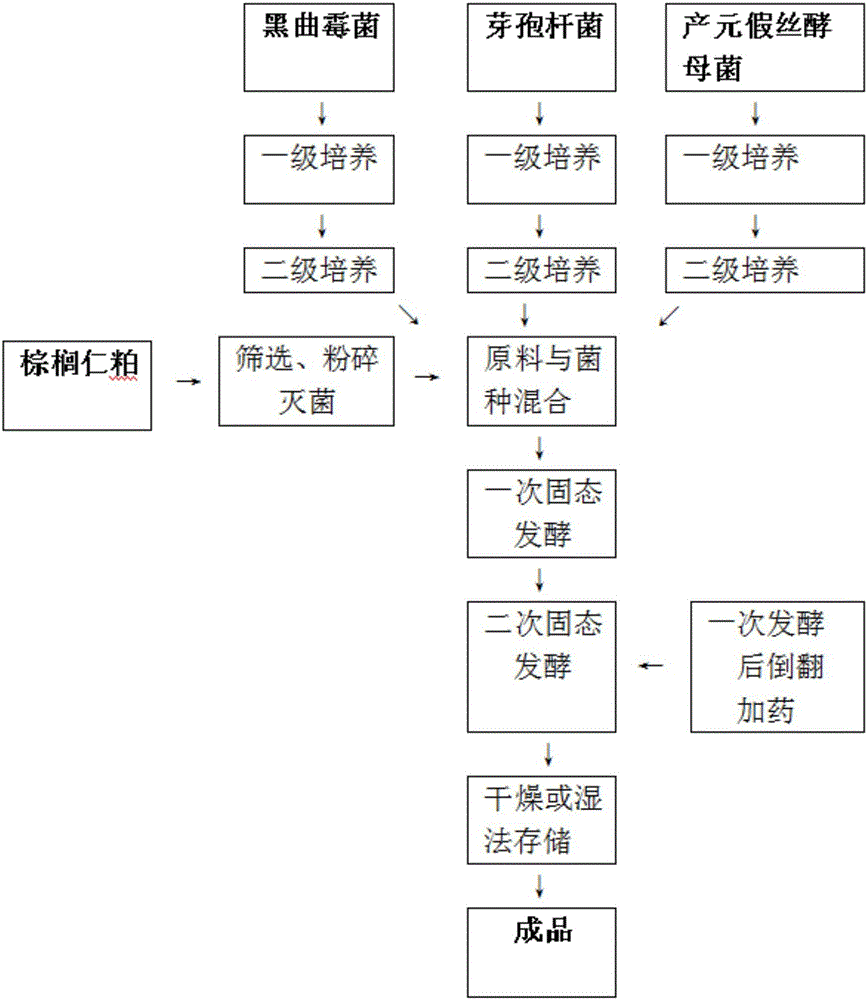

[0047] Present embodiment provides a kind of method of solid-state fermentation to produce palm kernel meal protein feed, as figure 1 As shown, the method specifically includes the following steps:

[0048] Step 1, seed solution preparation:

[0049] Bacillus, Candida metagenetica and Aspergillus niger were respectively subjected to primary seed cultivation and secondary seed expansion cultivation. The cultivation temperature of the primary seed cultivation was 30-40°C, the cultivation time was 24h, and the rotation speed was 150-170r / min, the cultivation temperature for secondary seed expansion cultivation is 25-37°C, the cultivation time is 24-72h, and the rotation speed is 150-170r / min, respectively prepared into Bacillus seed liquid, yeast seed liquid and Aspergillus niger seed liquid;

[0050] The Aspergillus niger is Aspergillus niger ASP-1.

[0051] In step 1, the preparation process of bacillus seed liquid is:

[0052] Step 1.1, first-level seed culture: pick a ri...

Embodiment 2

[0065] Present embodiment provides a kind of method of solid-state fermentation to produce palm kernel meal protein feed, as figure 1 As shown, the method specifically includes the following steps:

[0066] Step 1, preparation of seed solution: same as in Example 1.

[0067] Step 2, material mixing:

[0068] The raw material is palm kernel meal, the palm kernel meal is crushed first, the palm kernel meal needs to be screened and then crushed to a size of 3-4mm, so as to increase the contact area with the bacteria and make the fermentation process more thorough. mix. Prepare 100kg of palm kernel meal raw material, add 30L of water to the crushed palm kernel meal, stir evenly, and sterilize at 121°C for 15 minutes, then insert 10kg of Bacillus secondary seed culture solution and Candida metagenes secondary 10kg of seed culture solution and 5kg of Aspergillus niger secondary seed solution are fully mixed to make a mixed material, and the moisture in the mixed material is contr...

Embodiment 3

[0072] Present embodiment provides a kind of method of solid-state fermentation to produce palm kernel meal protein feed, as figure 1 As shown, the method specifically includes the following steps:

[0073] Step 1, preparation of seed solution: same as in Example 1.

[0074] Step 2, material mixing:

[0075] The raw material is palm kernel meal, the palm kernel meal is crushed first, the palm kernel meal needs to be screened and then crushed to a size of 3-4mm, so as to increase the contact area with the bacteria and make the fermentation process more thorough. mix. Prepare 100 kg of palm kernel meal raw material, add 10 L of water to the crushed palm kernel meal, stir evenly, and sterilize at 121°C for 15 minutes, then insert 20 kg of Bacillus secondary seed culture solution and Candida metagenes secondary 20kg of seed culture solution and 10kg of Aspergillus niger secondary seed solution are fully mixed to make a mixed material, and the moisture in the mixed material is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com