Low hygroscopicity gliquinone tablet and preparation method thereof

A technology for gliquidone and glitazone tablets, which is applied in the field of low-hygroscopicity glitazone tablets and their preparation, can solve the problems of reduced physical, chemical and biological stability and the like, and achieves reduced hygroscopicity, good stability, Tablet easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 preparation of low hygroscopicity gliquinone sheet

[0041] Weigh 35 parts of lactose, 5 parts of microcrystalline cellulose, 35 parts of ethyl cellulose, 1.9 parts of pluronic, 10 parts of magnesium aluminum silicate and 2.0 parts of talcum powder as auxiliary materials, set aside. The raw material drug is gliquidone.

[0042] The preparation method is as follows:

[0043] (1) Pass the lactose, microcrystalline cellulose, ethyl cellulose and magnesium aluminum silicate in the auxiliary materials through a 150-mesh sieve respectively, and set aside.

[0044] (2) Dissolve Pluronic in 30% (v / v) aqueous ethanol to obtain a Pluronic solution for later use.

[0045](3) Weigh the raw material drug of gliquidone according to the prescription amount, first mix the gliquidone, lactose and microcrystalline cellulose with the method of equal addition, then add ethyl cellulose and magnesium aluminum silicate and mix well , Stirring, spraying and adding Pluronic solu...

Embodiment 2

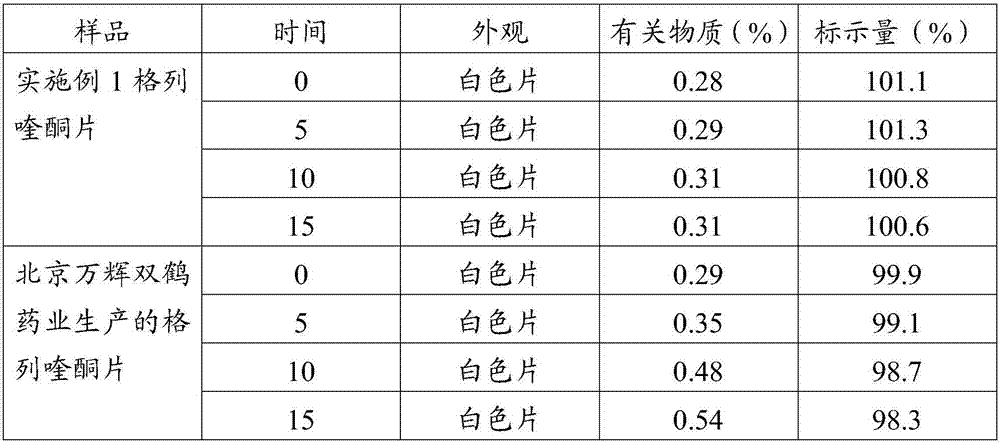

[0047] Embodiment 2 Gliquidone Tablet Quality Detection

[0048] 1. Dissolution testing

[0049] The dissolution rate was determined according to the second method of Appendix XC of the 2010 edition of the Chinese Pharmacopoeia. Get the gliquidone tablet obtained in Example 1, use phosphate buffer (10 g of disodium hydrogen phosphate, add 1000 ml of water, adjust the pH value to 8.5 with phosphoric acid) 500 ml as the dissolution medium, the rotating speed is 75 rpm, and the temperature is 37 ° C ±0.5℃, operate according to law. After 45min, the solution was taken and filtered, and the filtrate was taken as the test solution.

[0050] Take about 30mg of gliquidone reference substance, accurately weigh it, put it in a 100ml measuring bottle, add 10ml of dimethylformamide to dissolve, dilute to the mark with the dissolution medium, shake well, accurately measure 10ml, put it in a 50ml measuring bottle , dilute to the mark with dissolution medium, shake well, and use it as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com