An integrated 3D laser printing multi-component preparation method

A technology of laser printing and 3D printer, which is applied in the field of integrated 3D laser printing multi-component preparation, achieving the effects of high reliability, simple steps and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

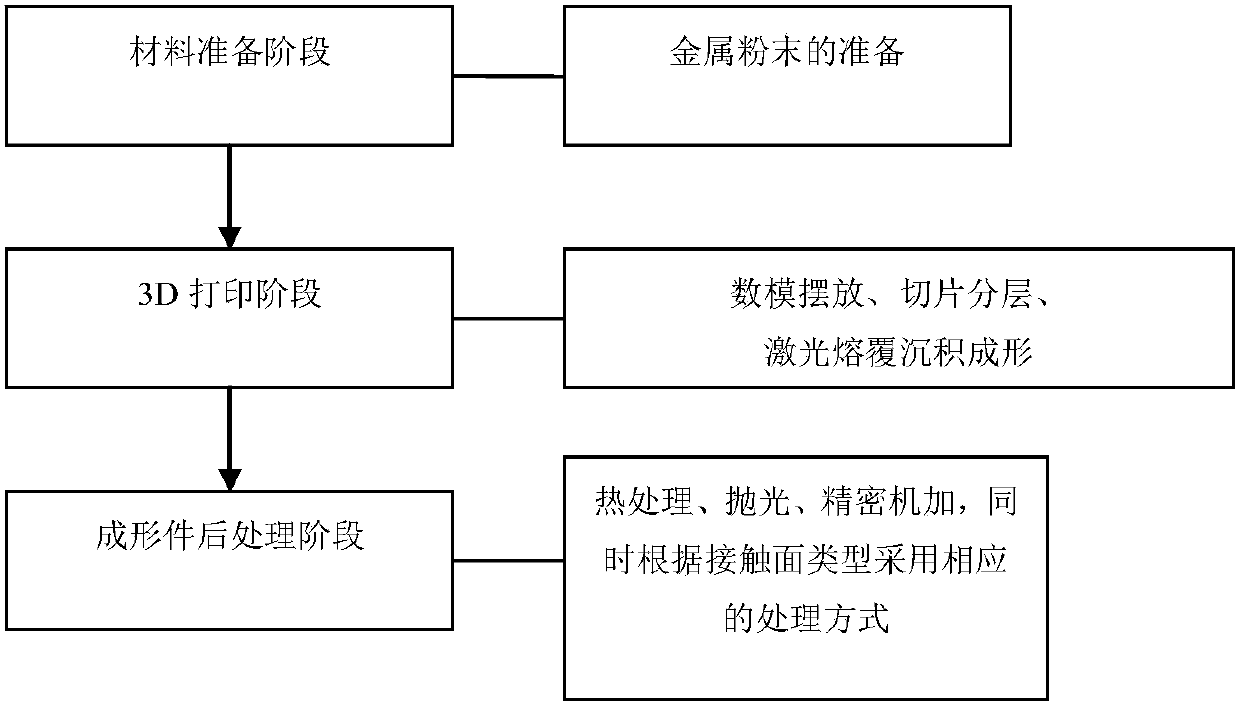

[0018] Attached below figure 1 The specific steps of an integrated 3D laser printing multi-component preparation method of the present invention are described in detail.

[0019] An integrated 3D laser printing multi-component preparation method, wherein the multi-component includes at least 2 components and is suitable for additive manufacturing technology, and the processing method includes the following steps:

[0020] 1) Material preparation stage: According to the design requirements of the types of multi-component metal powders, the different metal powders are fully and uniformly mixed with a powder mixer according to the proportion, and the mixed powders are placed in a drying oven at 100-200 ° C for drying. Dry for 1-1.5 hours; place the dried composite powder in the powder cartridge of the powder feeder of the 3D printer for spare use, wherein the particle size of the metal powder is 50-300 μm;

[0021] 2) 3D printing stage: in the forming room of the additive manufa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com