Respiration type pressurized drying method for rotary cut veneer, and production method for solid-wood composite floor

A technology of solid wood composite flooring and drying method, which is applied in the field of pressure drying of rotary cut veneer, which can solve the problems of uneven glue application on the front and back sides, stress reduction, board warping, twisting, etc., so as to reduce glue opening and increase Adhesive performance, the effect of ensuring flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

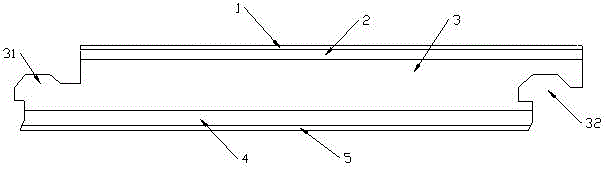

Image

Examples

Embodiment 1

[0019] Example 1: Preparation of five-layer solid wood composite flooring based on breathing pressurized drying

[0020] (1) veneer rotary cutting

[0021] The veneer with a thickness of 8 mm is peeled by using pine wood segments under the condition of hydrothermal treatment, and the 3.5 mm eucalyptus veneer is peeled by using eucalyptus wood segments.

[0022] (2) Veneer breathing pressurized drying

[0023] Put the rotary-cut veneer with a thickness of 8mm in a pressure dryer (such as a hot press) at a temperature of 120°C, and apply a pressure of 1-2kg / cm to the slab with a hot press 2 , After holding the pressure for 80-120s, raise the hot pressing plate, and press the thick veneer again with the hot pressing plate after 80s. Repeat this for about 15 times until the moisture content of the thick veneer is reduced to below 3%. Then, place the thick veneer in the air to naturally absorb moisture to a moisture content of 6-8%. After standing for 24 hours, the warpage of t...

Embodiment 2

[0035] Embodiment 2: Preparation of three-layer solid wood composite floor based on breathing pressurized drying

[0036] (1) veneer rotary cutting

[0037] The veneer with a thickness of 14 mm is peeled by using pine wood segments under the condition of hydrothermal treatment, and the 2 mm eucalyptus veneer is peeled by using eucalyptus wood segments.

[0038] (2) Veneer breathing pressurized drying

[0039] Place the 14mm thick rotary cut veneer in a pressure dryer (such as a hot press) at a temperature of 200°C, and apply a pressure of 2-3kg / cm to the slab with a hot press 2 , After holding the pressure for 500-560s, raise the hot pressing plate, and press the thick veneer again with the hot pressing plate after 500s. Repeat this about 4 times until the moisture content of the thick veneer is reduced to below 3%. Then, place the thick veneer in the air to naturally absorb moisture to a moisture content of 10-12%. After standing for 24 hours, the warpage of the thick rot...

Embodiment 3

[0049] Example 3: Preparation of seven-layer solid wood composite flooring based on breathing pressurized drying

[0050] (1) veneer rotary cutting

[0051] The veneer with a thickness of 5 mm is peeled by using pine wood segments under the condition of hydrothermal treatment, and the 2 mm eucalyptus veneer is peeled by using eucalyptus wood segments.

[0052] (2) Veneer breathing pressurized drying

[0053] Put the rotary cut veneer with a thickness of 5mm in a pressure dryer (such as a hot press) at a temperature of 180°C, and apply a pressure of 1-2kg / cm to the slab with a hot press 2 , After holding the pressure for 100-150s, raise the hot pressing plate, and press the thick veneer again with the hot pressing plate after 25s. Repeat this about 10 times until the moisture content of the thick veneer is reduced to below 3%. Then, place the thick veneer in the air to naturally absorb moisture to a moisture content of 8-10%. After standing for 24 hours, the warpage of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com