Method for preparing decorative glass with molten high-temperature phosphorous slag

A molten state and decorative surface technology, applied in the field of solid waste recycling, can solve the problems of high energy consumption, high production cost, waste of heat energy, etc., and achieve the effects of reducing threats, saving energy consumption, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

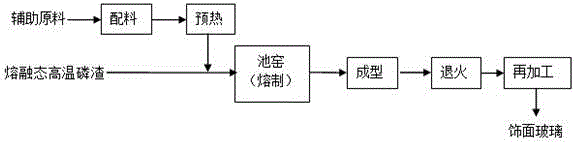

Method used

Image

Examples

Embodiment 1

[0023] The method for preparing decorative glass using molten high-temperature phosphorus slag liquid described in this embodiment specifically includes the following steps:

[0024] (1) Use quartz sand, soda ash, and fluorite as auxiliary materials, use hot air to dry the auxiliary materials, ball mill after drying, and sieve the auxiliary materials through a 40-mesh sieve, according to the mass ratio of quartz sand, soda ash, and fluorite: 25:4:1 After weighing the auxiliary materials and mixing them evenly, put them into the kiln and preheat to 1350°C for later use;

[0025] (2) According to the mass ratio of phosphorus slag liquid to auxiliary raw materials 62:29, the high-temperature phosphorus slag liquid discharged from the electric phosphorus furnace flows into the pool kiln through the liquid flow tank, and the auxiliary materials in the above step (1) are synchronously put into the pool kiln According to the heating rate of 10°C / min, the phosphorus slag liquid and au...

Embodiment 2

[0029] The method for preparing decorative glass using molten high-temperature phosphorus slag liquid described in this embodiment specifically includes the following steps:

[0030] (1) Use quartz sand, soda ash, and fluorite as auxiliary materials, dry the auxiliary materials with hot air, ball mill after drying, and sieve the auxiliary materials through a 40-mesh sieve. The mass ratio of quartz sand, soda ash, and fluorite is 31:3:1 After weighing the auxiliary materials and mixing them evenly, put them into the kiln and preheat to 1400°C for later use;

[0031] (2) According to the mass ratio of phosphorus slag liquid to auxiliary raw materials 62:38, the high-temperature phosphorus slag liquid discharged from the electric phosphorus furnace flows into the pool kiln through the liquid flow tank, and the auxiliary materials in the above step (1) are synchronously put into the pool kiln According to the heating rate of 10°C / min, the phosphorous slag liquid and auxiliary mate...

Embodiment 3

[0035] The method for preparing decorative glass using molten high-temperature phosphorus slag liquid described in this embodiment specifically includes the following steps:

[0036] (1) Use quartz sand, soda ash, and fluorite as auxiliary materials, dry the auxiliary materials with hot air, ball mill after drying, and sieve the auxiliary materials through a 40-mesh sieve, according to the mass ratio of quartz sand, soda ash, and fluorite: 28:5:2 After weighing the auxiliary materials and mixing them evenly, put them into the kiln and preheat to 1400°C for later use;

[0037] (2) According to the mass ratio of phosphorus slag liquid to auxiliary raw materials 65:35, the high-temperature phosphorus slag liquid discharged from the electric phosphorus furnace flows into the pool kiln through the liquid flow tank, and the auxiliary materials in the above step (1) are synchronously put into the pool kiln According to the heating rate of 5°C / min, the phosphorus slag liquid and auxil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com