Polyethylene glycol terephthalate plastic film used for heating cable

A polyethylene terephthalate film, polyethylene terephthalate technology, applied in the direction of insulated cables, plastic/resin/wax insulators, cables, etc., can solve the quality and flame retardancy of heating cables High temperature resistance, mechanical strength, hardness can not meet the needs of product use, restrict the development of polyethylene terephthalate, product shrinkage and other problems, to achieve the effect of excellent chemical stability, good chemical stability, good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

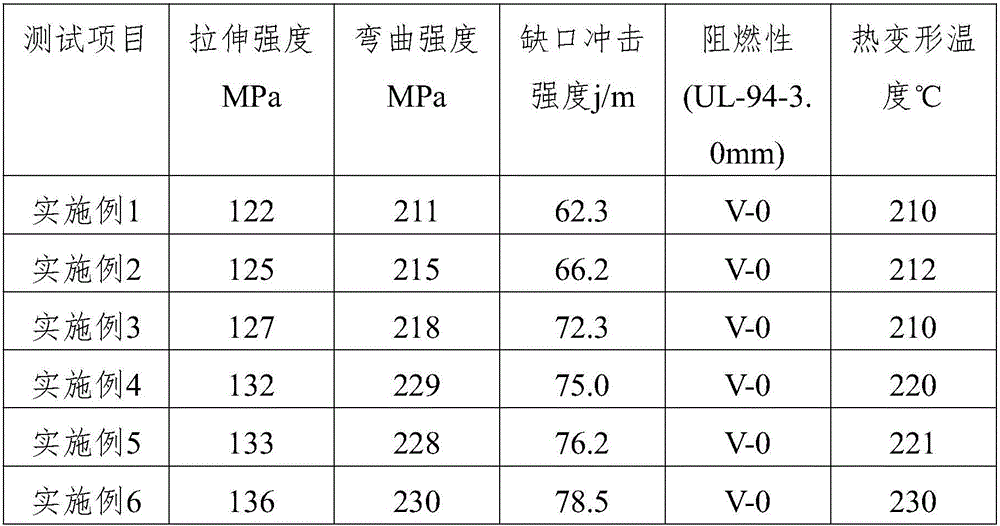

Examples

Embodiment 1

[0017] 本发明提供了一种发热电缆用聚对苯二甲酸乙二醇酯膜塑料,由以下重量份数的原料制备而成:聚对苯二甲酸乙二醇酯:20份、聚二甲基硅氧烷:10份、硬脂酸锌:5份、磷酸三苯酯:1份、植物粉末:2份、6-乙氧基-2,2,4-三甲基-1,2-二氢化喹啉硫醚:2份、增强纤维:3份、邻苯二甲酸二丁酯:2份、聚四氟乙烯:2份、油酸:2份、高岭土:3份;

Embodiment 2

[0019] 本发明提供了一种发热电缆用聚对苯二甲酸乙二醇酯膜塑料,由以下重量份数的原料制备而成:聚对苯二甲酸乙二醇酯:50份、聚二甲基硅氧烷:20份、硬脂酸锌:12份、磷酸三苯酯:9份、植物粉末:6份、6-乙氧基-2,2,4-三甲基-1,2-二氢化喹啉硫醚:8份、增强纤维:5份、邻苯二甲酸二丁酯:10份、聚四氟乙烯:10份、油酸:8份、高岭土:10份;

Embodiment 3

[0021] 本发明提供了一种发热电缆用聚对苯二甲酸乙二醇酯膜塑料,由以下重量份数的原料制备而成:聚对苯二甲酸乙二醇酯:25份、聚二甲基硅氧烷:12份、硬脂酸锌:6份、磷酸三苯酯:2份、植物粉末:4份、6-乙氧基-2,2,4-三甲基-1,2-二氢化喹啉硫醚:3份、增强纤维:3份、邻苯二甲酸二丁酯:3份、聚四氟乙烯:4份、油酸:3份、高岭土:6份;

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com