Stannic oxide modified ferroferric oxide/multiwalled carbon nanotube network composite material

A technology of multi-wall carbon nanotubes and ferroferric oxide, which is applied in the field of composite materials, can solve the problems of reduced surface utilization, multi-wall carbon nanotubes have no magnetic loss, and cannot achieve microwave efficient absorption, etc., and achieve microwave absorption performance Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

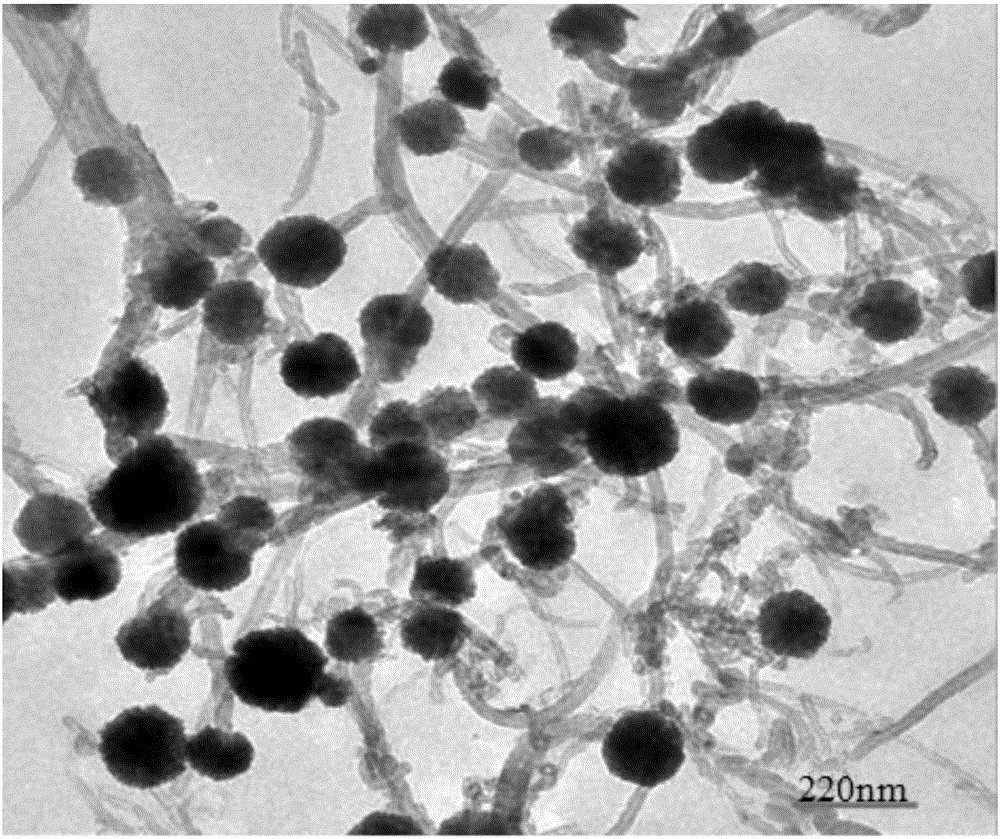

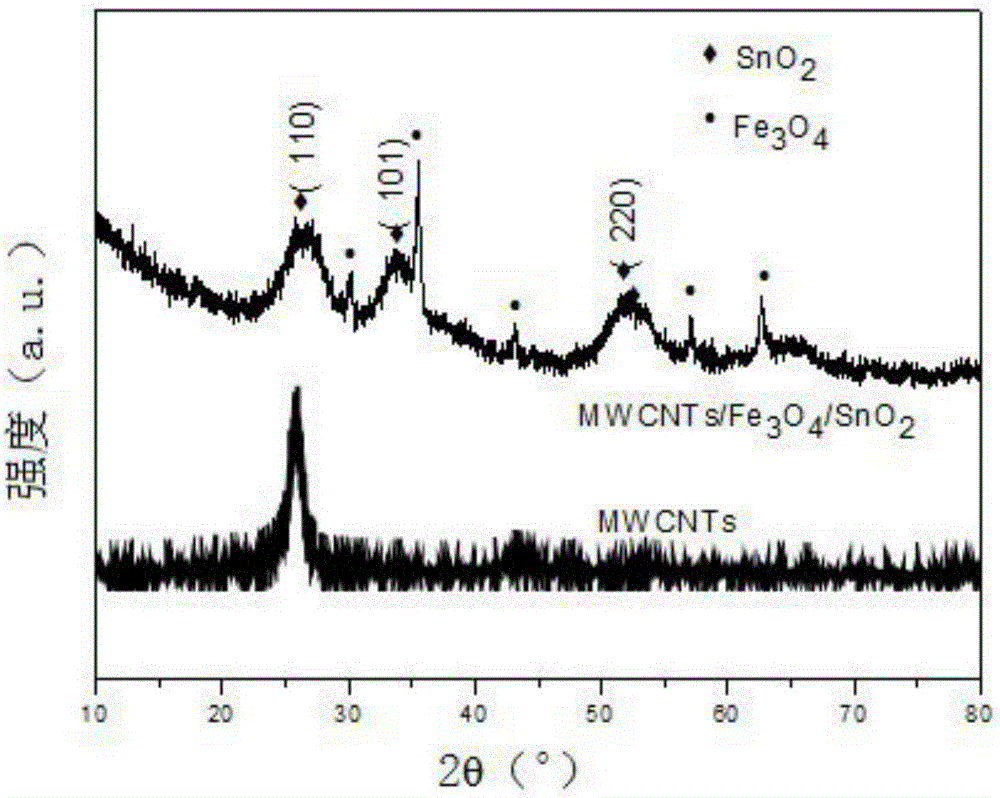

[0029] Add 70mL ethylene glycol and 80mg acidified multi-walled carbon nanotubes (acidification conditions: concentrated nitric acid refluxed at 120°C for 6 hours) into the beaker, ultrasonically disperse for 2 hours, then add 1mmol Fe(NO 3 ) 3 9H 2 O, 2mmol NaAc 3H 2 O, stirred and dissolved, transferred to a reaction kettle at 200°C for 10 hours. The product was washed thoroughly with distilled water to neutralize its pH. The product was placed in a drying oven and dried at 60° C. for 8 hours to obtain a composite multi-walled carbon nanotube material of ferric oxide. Its TEM picture is as follows figure 1 shown. It can be seen from the figure that the diameter of the multi-walled carbon nanotubes is 40-60 nm, and the length is in the order of microns. The ferroferric oxide microspheres have a particle size of 180-200nm and are self-assembled by nanometer ferroferric oxide. The multi-walled carbon nanotubes connect ferric oxide microspheres to form a network.

[0030...

Embodiment 2

[0033] Fe(NO 3 ) 3 9H 2 The amount of O added is 2mmol, NaAc·3H 2 The amount of O added is 4mmol, SnCl 4 ·5H 2 O was added in an amount of 4 mmol. The rest is the same as in Example 1, and the tin dioxide-modified ferric oxide / multi-walled carbon nanotube network composite material is obtained.

Embodiment 3

[0035] The volume of ethylene glycol added to the beaker is 60mL. The rest is the same as in Example 1, and the tin dioxide-modified ferric oxide / multi-walled carbon nanotube network composite material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com