Etchant composition and manufacturing method of an array substrate for liquid crystal display

A composition and etchant technology, applied in the directions of surface etching compositions, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve the problem of low etching rate variation with time, unfavorable process limitations, inability to etch amorphous silicon problems such as thin layers to achieve the effect of reducing processing time and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5 and comparative example 1 and 2

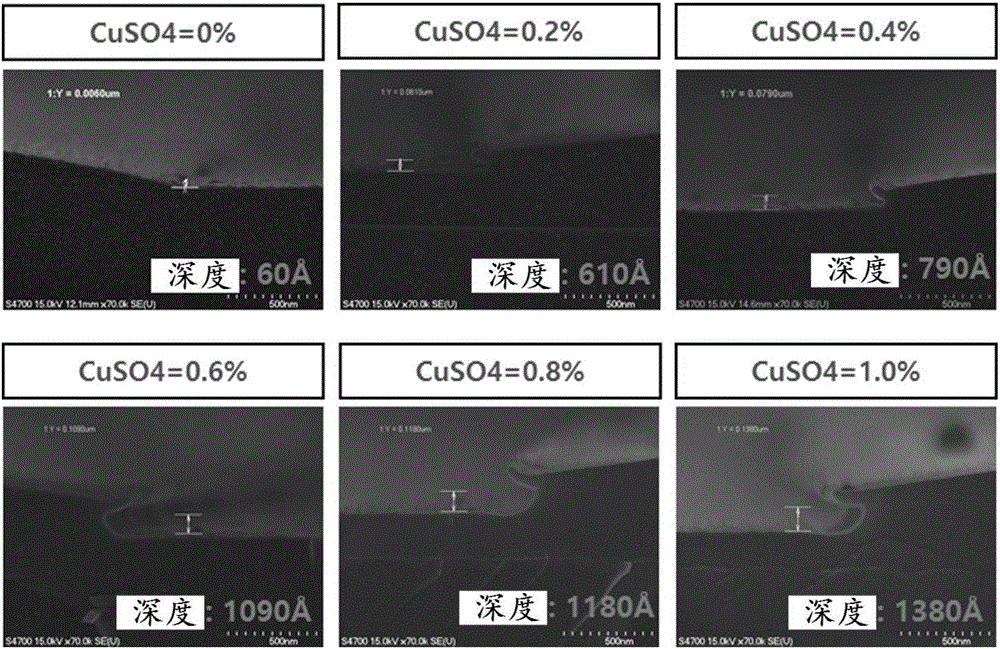

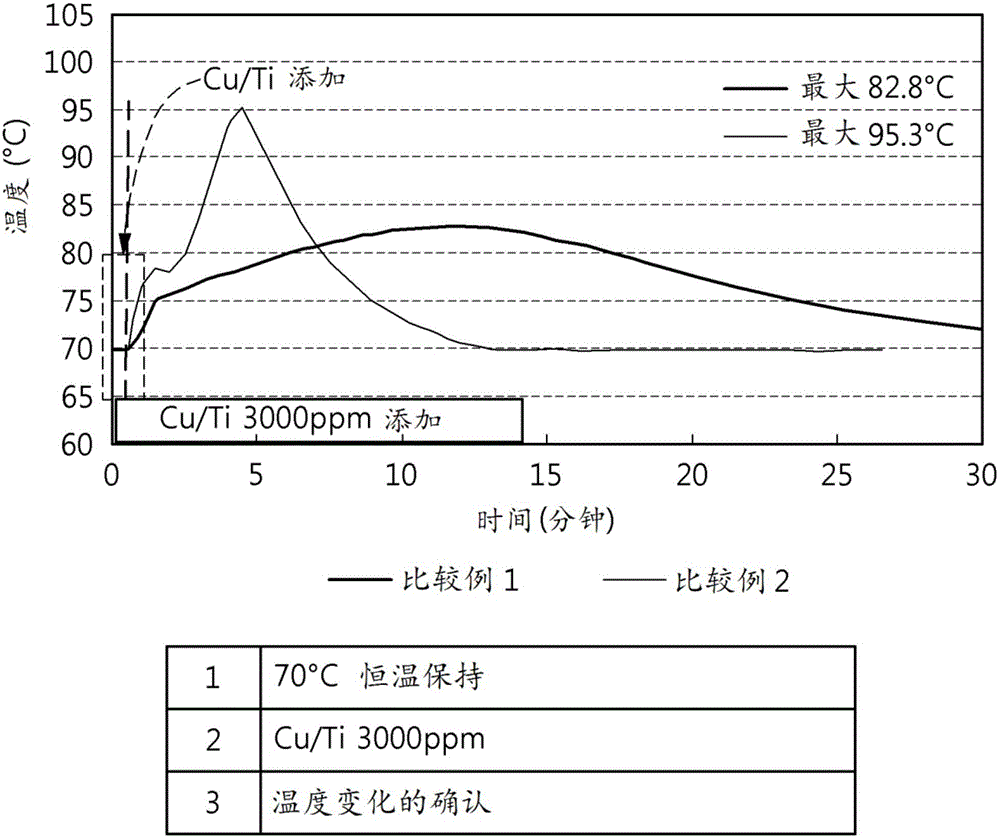

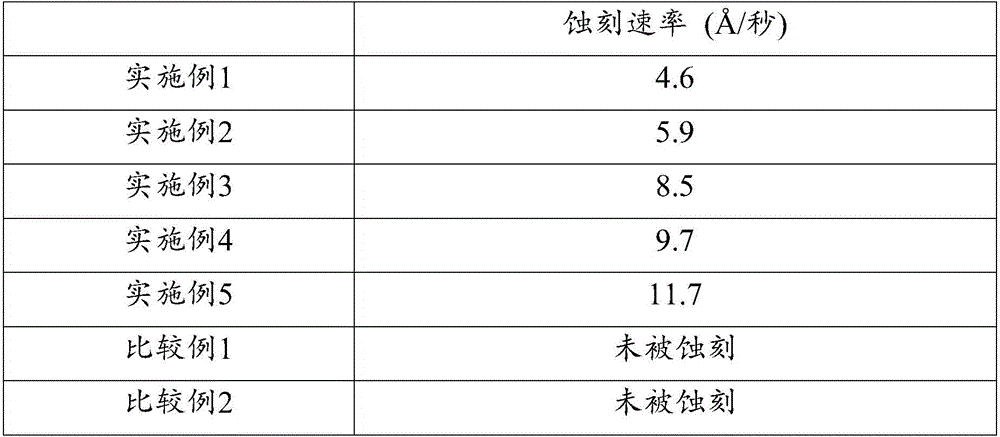

[0036] Examples 1-5 and Comparative Examples 1 and 2: Preparation of etchant compositions

[0037] An etchant composition was prepared using the ingredients in the amounts (wt %) shown in Table 1 below.

[0038] [Table 1]

[0039]

APS

AF

HNO 3

ATZ

p-TSA

A.A.

AcOH

CuSO 4

water

Example 1

15

0.7

3

1.2

3.0

2.5

8.0

0.2

margin

Example 2

15

0.7

3

1.2

3.0

2.5

8.0

0.4

margin

Example 3

15

0.7

3

1.2

3.0

2.5

8.0

0.6

margin

Example 4

15

0.7

3

1.2

3.0

2.5

8.0

0.8

margin

Example 5

15

0.7

3

1.2

3.0

2.5

8.0

1.0

margin

Comparative example 1

15

0.7

3

1.2

3.0

2.5

8.0

-

margin

Comparative example 2

15

0.7

3

1.2

0.0

2.5

8.0

-

margin

[0040] *APS: Ammonium persulfate

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com