Drying treatment system after soaking the dregs after pressing

A technology for drying treatment and medicinal residues, which is applied in the directions of drying, drying machine, and preliminary treatment to promote the drying of solid materials, can solve the problems of unsatisfactory treatment of wet medicinal residues, complicated equipment, etc., and achieves a reduction in waste disposal The cost, the effect is good, the effect of saving the processing fee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

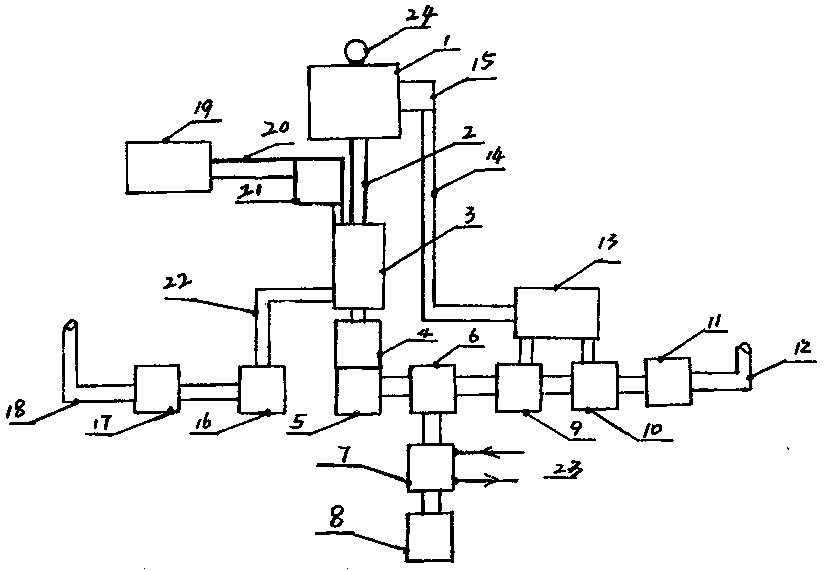

[0014] Design the drying treatment system after pressing the soaked medicinal dregs, including: press machine 19, drying drum feeding device 21, drying drum 3, pulverizer 5, induced draft fan 11, water mist dust removal exhaust pipe 18. Air-flow bed drying equipment 6, material receiving device 13, boiler feed bin 15 and boiler 1. Its characteristics are: 1. The squeezer 19 squeezes the dregs of the soaked medicine, and squeezes the dregs after being squeezed by the squeezer. The dregs are soaked and transported to the drying drum 3 through the belt 20 and the drying drum feeding device 21. One end of the drying drum is connected to the heat output port of the boiler 1 through the hot air pipe 2 for The drying drum 3 provides a drying heat source; the other end of the drying drum 3 is provided with an air material pipe 22, and the end of the air material pipe is provided with a cyclone dust collector 16, and the output end of the cyclone dust collector is connected with Blower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com