Handling method for epitaxy defect

A technology of epitaxial defects and processing methods, which is applied in the field of epitaxial defect processing, can solve the problems of increased internal leakage of devices, reduced internal quantum efficiency, and deterioration of fill factor open circuit voltage performance, so as to reduce leakage and non-radiative recombination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention should not be limited thereby.

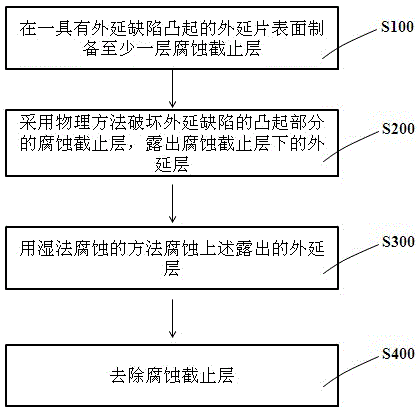

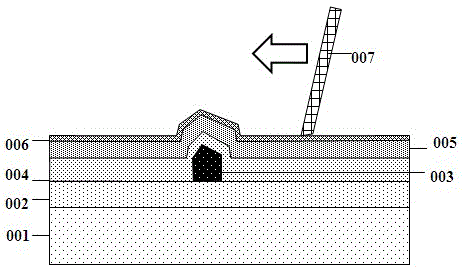

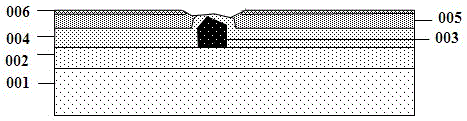

[0030] The following embodiment discloses a processing method for epitaxial defects caused by epitaxial dropout phenomenon, please refer to figure 1 , which mainly includes steps S100~S400, first forming an etch stop layer on the surface of the epitaxial layer, then combining physical and chemical methods, using physical methods to destroy the etch stop layer of the raised part of the epitaxial defect, in the chemical wet etching process The corrosion stop layer only protects the epitaxial layer other than the raised position, and realizes the selective etching and passivation of the epitaxial layer at the raised defect position.

[0031] Taking a multi-junction solar cell as an example, the method for manufacturing a semiconductor device using the above processing method will be described in detail be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com