Composition for fabric softener

A technology of softener and composition, which is applied in the field of fiber softener composition, can solve the problems of inability to fully exert the effect of organic acid, organic acid diffusion (slow dissolution, etc.), achieve strong aftertaste, improve solubility, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

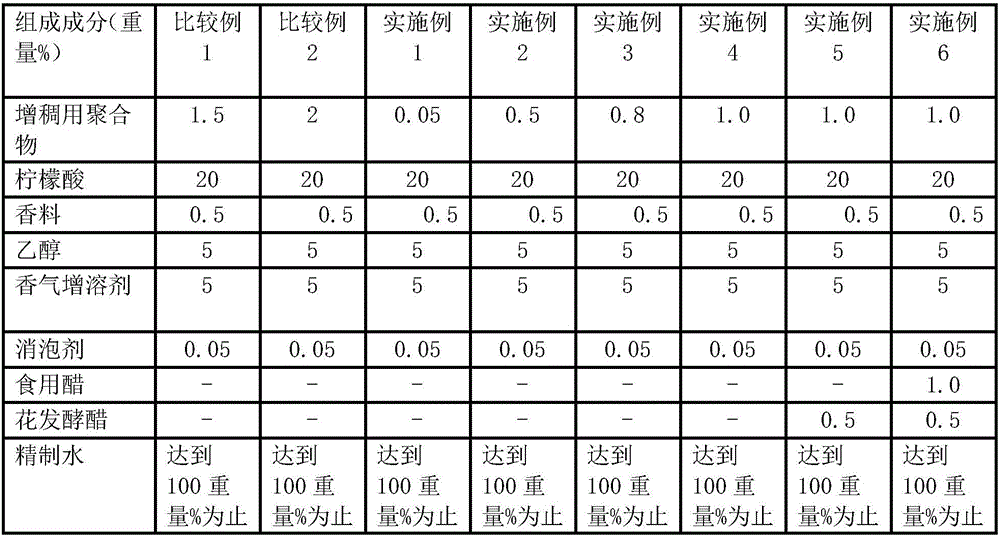

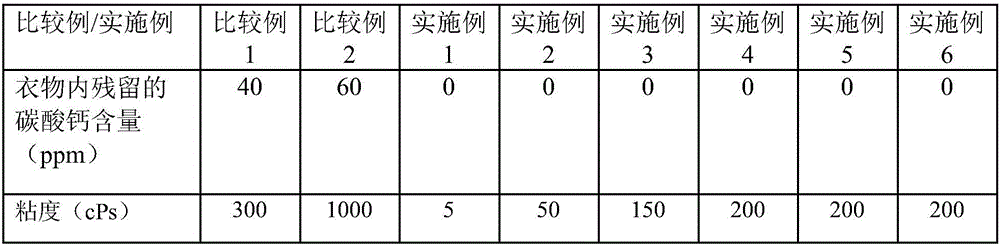

Embodiment 1~6 and comparative example 1~2

[0053] A fiber softener composition having the composition and content shown in Table 1 below was prepared.

[0054] First, put the thickening polymer into purified water, stir well until it is completely dissolved, then add citric acid, flower fermented vinegar, and edible vinegar to it and stir for 30 minutes, then add ethanol, flavors, and additives dissolved in advance The solution was stirred for 30 minutes to prepare a fiber softener composition.

[0055] As the additive, a mixture of an aroma solubilizer (5% by weight) and a defoamer (0.05% by weight) was used. As the thickening polymer, an acrylic copolymer (Rheovis FRC from BASF) was used. As the organic acid, citric acid was used.

[0056] The vinegar uses brewed vinegar (natural food).

[0057] In addition, flower fermented vinegar is obtained by washing jasmine petals with water and then drying them, then mixing 15 parts by weight of edible vinegar and 15 parts by weight of sugar water with respect to 1 part by ...

experiment example 1

[0061] Experimental example 1: Measurement of residual calcium carbonate concentration in clothes after washing

[0062] After washing and rinsing using the fabric softener compositions produced in the above Examples and Comparative Examples, the concentration of calcium carbonate remaining in the clothes was measured.

[0063] The washing conditions followed the experimental method of EL306 (fiber softener) in the environmental label certification standard of the Korea Institute of Environmental Industry and Technology, and the usage amount of the fiber softener composition in the last rinse was 0.67mL / L.

[0064] The analysis of the residual amount of calcium carbonate remaining in the clothes after washing and rinsing is carried out by taking 0.5 g of the test cloth which has been washed and rinsed under the above washing conditions, and acidifying it with a mixture of hydrochloric acid, hydrofluoric acid, nitric acid and boric acid. After the treatment, extraction was perf...

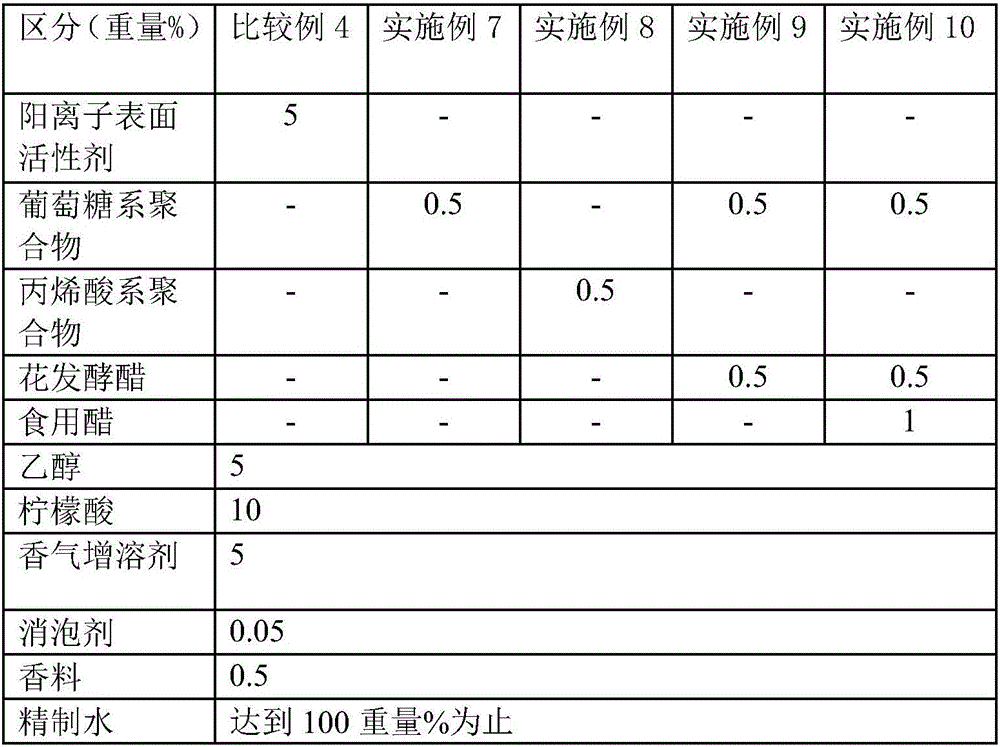

Embodiment 7~10

[0071] A fiber softener composition having the composition and content shown in Table 3 below was prepared.

[0072] First, a cationic polymer, flower fermented vinegar, edible vinegar, and citric acid were put into purified water and stirred for 30 minutes, then a solution in which ethanol, fragrance, aroma solubilizer, and antifoaming agent were dissolved was added, and stirred for 30 minutes. Fiber softener composition.

[0073] In addition, as a glucose-based polymer, a commercially available polyquaternium salt (Polymer LR30M of DOW Chemical Company) was used; as an acrylic polymer, a commercially available acrylic acid copolymer (Rheovis FRC of BASF Company) was used. .

[0074] In addition, the vinegar uses brewed vinegar (natural food).

[0075] In addition, the flower fermented vinegar used is after washing the jasmine petals with water and then drying them, then mixing 15 parts by weight of edible vinegar and 15 parts by weight of sugar water with the dried petals,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com