Drying system and method for fruit and vegetable slices by utilizing exhaust steam heat of residual heat recovery system

A technology of waste heat recovery system and drying system, which is applied in application, food processing, food science, etc., and can solve the problems of increased production cost, large equipment investment, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

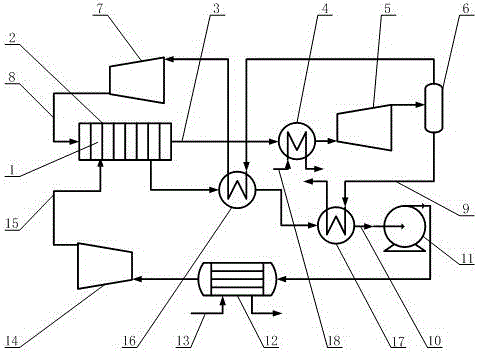

[0010] Refer to the attached figure 1 Explain the operation process of the fruit and vegetable chip drying system using the waste heat recovery system to exhaust steam heat. First, the air circulation loop can be vacuumed as needed.

[0011] The air 8 from the outlet of the compressor 7 enters the cold side of the drying box 2, and the high-temperature exhaust steam 15 of the working medium passes through the hot side of the drying box 2 to heat the material on the cold side; the mixture of the fruit and vegetable slices 1 and the air 8 in the drying box 2 is heated After the temperature rises, the air 8 mixes with the water vapor evaporated from the fruit and vegetable slices 1 to become high-temperature humid air 3, and the fruit and vegetable slices 1 are dried; the high-temperature and humid air 3 is discharged from the gas phase outlet of the drying box and enters the first condenser The hot side of 4 releases latent heat and sensible heat to the room temperature liquid w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com