Aqueous caprolactam solution concentration and reuse apparatus and technology thereof

A caprolactam, aqueous solution technology, applied in evaporator regulation/control, steam pressurized evaporation, multi-effect evaporation, etc., can solve the problems of low enthalpy value, high energy consumption, high cost, and achieve low operating cost, high thermal efficiency, The effect of low unit energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

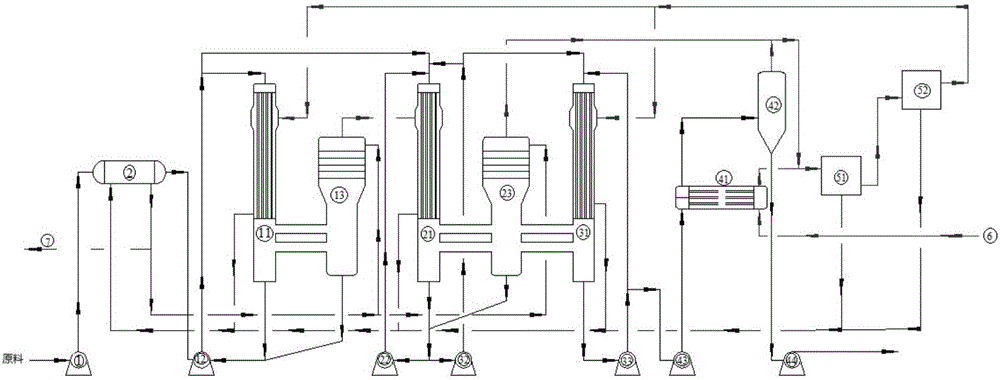

[0027]Embodiment 1: A concentrated recycling device for caprolactam aqueous solution, comprising a feed pump 1, a raw material preheater 2, a first-effect concentration system, a second-effect concentration system, a three-effect concentration system, a four-effect concentration system and a compression system; Described one-effect concentration system comprises one-effect falling film evaporator 11, one-effect feed / circulation pump 12 and one-effect gas-liquid separator 13; Described two-effect concentration system comprises two-effect falling-film evaporator 21, two-effect Feed / circulation pump 22 and two-effect gas-liquid separator 23; Described three-effect concentration system comprises three-effect falling film evaporator 31, three-effect feed pump 32 and three-effect circulation pump 33; Described four-effect concentration system comprises Four-effect forced circulation heater 41, four-effect forced circulation separator 42, four-effect feed pump 43 and product delivery ...

Embodiment 2

[0036] Embodiment 2: The device in the present embodiment is the same as in Embodiment 1, and the specific process for concentrating and recycling the caprolactam aqueous solution includes the following steps:

[0037] (1) Before the operation of the system, 0.5MPa fresh steam is used to establish the steam balance of the whole system, and it is continuously input during the whole treatment process;

[0038] (2) Pass the aqueous solution containing 10wt% caprolactam from the nylon 6 slicing device into the raw material preheater at a flow rate of 10000kg / h for preheating, the preheating temperature is 82°C, and the raw material is passed into the first-effect falling film evaporator after the temperature reaches , heated to 125°C in the first-effect falling film evaporator, at this time the boiling point of the material is 120°C, and the concentration of caprolactam in the first-effect concentrated solution produced is 25wt%; the produced one-effect concentrated solution is inp...

Embodiment 3

[0039] Embodiment 3: The device in the present embodiment is the same as in Embodiment 1, and the specific process for concentrating and recycling the caprolactam aqueous solution includes the following steps:

[0040] (1) Before the operation of the system, first use 1MPa fresh steam to establish the steam balance of the whole system, and continuously input it in the whole treatment process;

[0041] (2) Pass the aqueous solution containing 10wt% caprolactam from the nylon 6 slicing device into the raw material preheater at a flow rate of 30000kg / h for preheating, the preheating temperature is 90°C, and the raw material is passed into the first-effect falling film evaporator after the temperature reaches , heated to 132°C in the first-effect falling film evaporator, at this time, the boiling point of the material is 123°C, and the caprolactam concentration in the produced first-effect concentrated solution is 30wt%; the produced one-effect concentrated solution is input by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com