Catalyst for catalytic oxidation of carbonic oxide and preparation method of catalyst

A carbon monoxide, catalytic oxidation technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

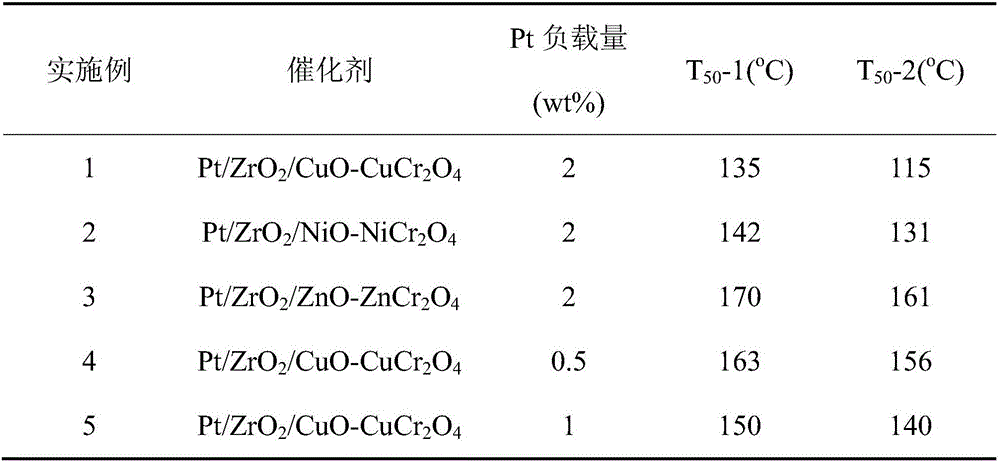

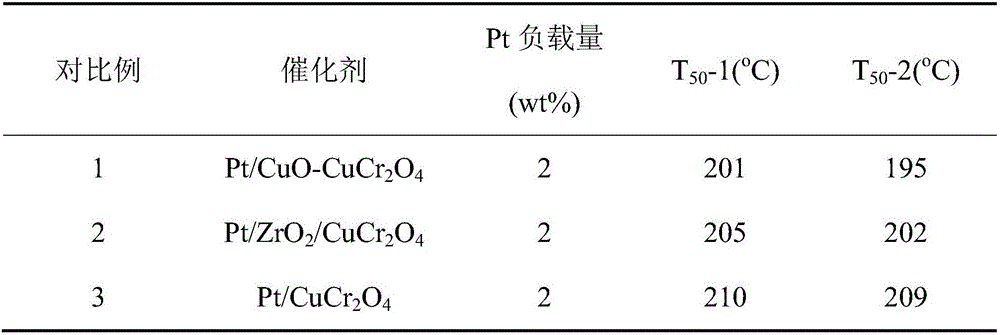

Examples

Embodiment 1

[0018] (1) According to Cu(NO 3 ) 2 ·3H 2 O, Cr(NO 3 ) 3 9H 2 The molar ratio of O and citric acid is 1:1:2, and 16.38g Cu(NO 3 ) 2 ·3H2 O, 27.12g Cr(NO 3 ) 3 9H 2 O and 28.50 g of citric acid were dissolved in 200 mL of deionized water, and the mixed solution was stirred in a water bath at 90 °C until it was in a gel state, then dried at 120 °C for 8 hours, and finally calcined at 600 °C for 4 h in an air atmosphere. Among them, Cr and part of Cu undergo a solid-state reaction to form CuCr 2 o 4 , the remaining Cu forms CuO, giving CuO and CuCr 2 o 4 Mixture, namely CuO-CuCr 2 o 4 powder.

[0019] (2) According to ZrO 2 in ZrO 2 / CuO-CuCr 2 o 4 The mass percent composition in powder is 5%, and 1.08g ZrO(NO 3 ) 2 2H 2 O was dissolved in 20 mL deionized water, and then ZrO(NO 3 ) 2 Add 9.5g CuO-CuCr to the aqueous solution 2 o 4 In the powder, immerse for 5 hours, then dry it in a water bath at 90°C, bake at 120°C for 8 hours, and finally bake at 400°C...

Embodiment 2

[0023] (1) According to Ni(NO 3 ) 2 ·6H 2 O, Cr(NO 3 ) 3 9H 2 The molar ratio of O and citric acid is 1:1:2, and 20.38g Ni(NO 3 ) 2 ·6H 2 O, 28.04g Cr(NO 3 ) 3 9H 2 O and 29.45g of citric acid were dissolved in 200mL of deionized water, and the mixed solution was stirred in a water bath at 90°C until it was in a gel state, then dried at 120°C for 8 hours, and finally calcined at 600°C for 4 hours in an air atmosphere. Among them, Cr and part of Ni undergo a solid-state reaction to form NiCr 2 o 4 , the remaining Ni forms NiO to give NiO and NiCr 2 o 4 Mixture, namely NiO-NiCr 2 o 4 powder.

[0024] (2) According to ZrO 2 in ZrO 2 / NiO-NiCr 2 o 4 The mass percent composition in powder is 5%, and 1.08g ZrO(NO 3 ) 2 2H 2 O was dissolved in 20 mL deionized water, and then ZrO(NO 3 ) 2 Add 9.5g NiO-NiCr to the aqueous solution 2 o 4 In the powder, immerse for 5 hours, then dry it in a water bath at 90°C, bake at 120°C for 8 hours, and finally bake at 400°...

Embodiment 3

[0028] (1) According to Zn(NO 3 ) 2 ·6H 2 O, Cr(NO 3 ) 3 9H 2 The molar ratio of O and citric acid is 1:1:2, and 19.91g Zn(NO 3 ) 2 ·6H 2 O, 26.79g Cr(NO 3 ) 3 9H 2 O and 28.13g of citric acid were dissolved in 200mL of deionized water, and the mixed solution was stirred in a water bath at 90°C until it was in a gel state, then dried at 120°C for 8 hours, and finally calcined at 600°C for 4 hours in an air atmosphere. Among them, Cr and part of Zn undergo a solid-state reaction to form ZnCr 2 o 4 , the remaining Zn forms ZnO, resulting in ZnO and ZnCr 2 o 4 Mixture, namely ZnO-ZnCr 2 o 4 powder.

[0029] (2) According to ZrO 2 in ZrO 2 / ZnO-ZnCr 2 o 4 The mass percent composition in powder is 5%, and 1.08g ZrO(NO 3 ) 2 2H 2 O was dissolved in 20 mL deionized water, and then ZrO(NO 3 ) 2 Add 9.5g ZnO-ZnCr to the aqueous solution 2 o 4 In the powder, immerse for 5 hours, then dry it in a water bath at 90°C, bake at 120°C for 8 hours, and finally bake a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com