Preparation method of carbon nanomaterial loaded nanometer ferrite hollow sphere

A nano-carbon material and nano-ferrite technology, which is applied in the preparation of nano-carbon material-loaded ferrite nano-hollow spheres, and in the field of nano-carbon material-loaded nano-ferrite hollow spheres, can solve the problem of destroying hollow nanostructures and template material particles. Large diameter, complex post-processing and other problems, to achieve the effect of uniform shape, low cost and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

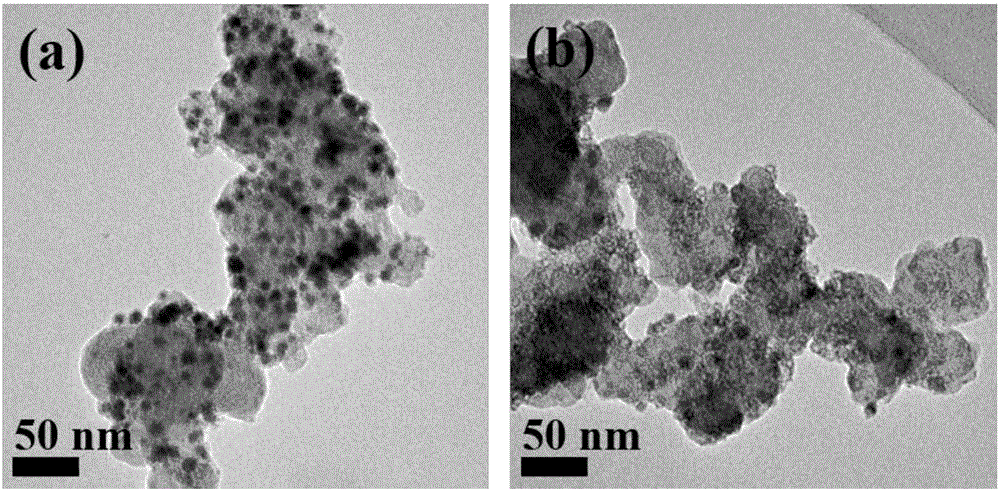

[0030] In this embodiment, at room temperature, 30 mg of Ag-MnFe 2 o 4 Core-shell nanoparticles were dispersed in 30mL of toluene, and 150mg of Vulcan XC-72 carbon black was added to it. After stirring for 24h, 80mL of methanol was added, centrifuged at 8000rpm for 15min, and the supernatant was removed to obtain carbon black-loaded Ag-MnFe 2 o 4 Core-shell nanoparticles, then add 100mL5mol / L saturated sodium chloride solution, stir for 48h and centrifuge at 8000rpm for 10min to obtain carbon black loaded MnFe 2 o 4 Nanohollow spheres, Ag-MnFe loaded on carbon black 2 o 4 Core-shell nanoparticles and carbon black supported MnFe2 o 4 Transmission electron microscope imaging of hollow nanospheres figure 1 shown.

Embodiment 2

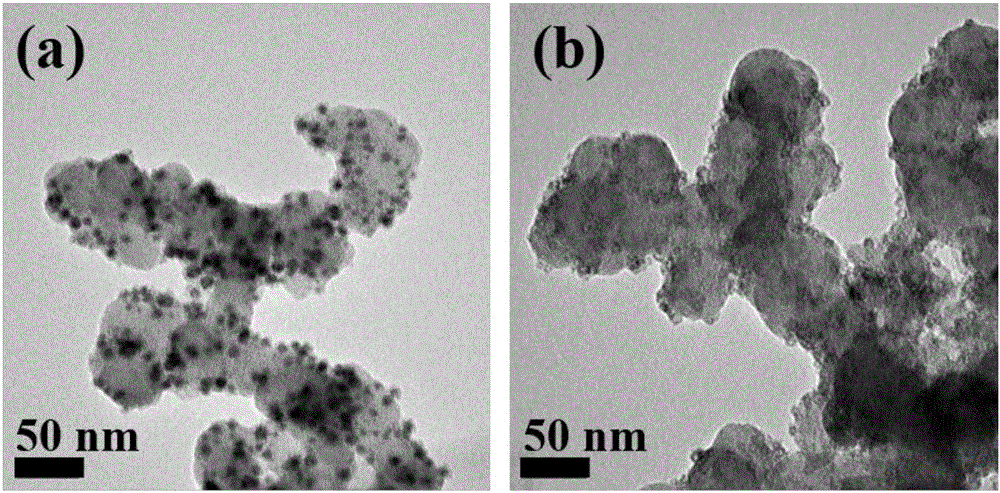

[0032] In this embodiment, at room temperature, 30 mg of Ag-CoFe 2 o 4 Core-shell nanoparticles were dispersed in 30 mL of toluene, 150 mg of Vulcan XC-72 carbon black was added to it, stirred for 24 hours, 100 mL of methanol was added, centrifuged at 8000 rpm for 15 minutes, and the supernatant was removed to obtain carbon black-loaded Ag-CoFe 2 o 4 Core-shell nanoparticles, then add 5mol / L sodium thiosulfate solution, stir for 48h and centrifuge at 8000rpm for 10min to obtain carbon black-loaded CoFe 2 o 4 Nano hollow spheres, Ag-CoFe loaded on carbon black 2 o 4 Core-shell nanoparticles and carbon black supported CoFe 2 o 4 Transmission electron microscope imaging of hollow nanospheres figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com