Pretreatment method for rapidly decreasing concentration of hexavalent chromium in waste water

A hexavalent chromium and pretreatment technology, applied in water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of separation and recovery of hexavalent chromium and magnetic particles, and the consumption of chemical agents Large volume, secondary pollution and other problems, to achieve the effect of reducing comprehensive treatment costs, good removal effect, and pressure relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take the concentration of hexavalent chromium as 300mg·L -1 1000mL of waste water, add 0.85gCa(OH) 2 and 0.93gAlCl 3 ·6H 2 O(Ca(OH) 2 and AlCl 3 ·6H 2 The molar ratio of O is 3:1, and the total mass is 1 times the stoichiometric amount required to generate chromate-type ettringite), the pH value of the solution is adjusted to 12.80 using NaOH, and then the reaction is stirred at 20°C for 4h, followed by vacuum The water pump is filtered to obtain chromium-containing sediment and clear liquid. Take the clear liquid to detect the concentration of hexavalent chromium, and the concentration is 115.35mg L -1 , the method reduces the concentration of hexavalent chromium in wastewater by 61.55% in a relatively short period of time, and better realizes the pretreatment process of wastewater.

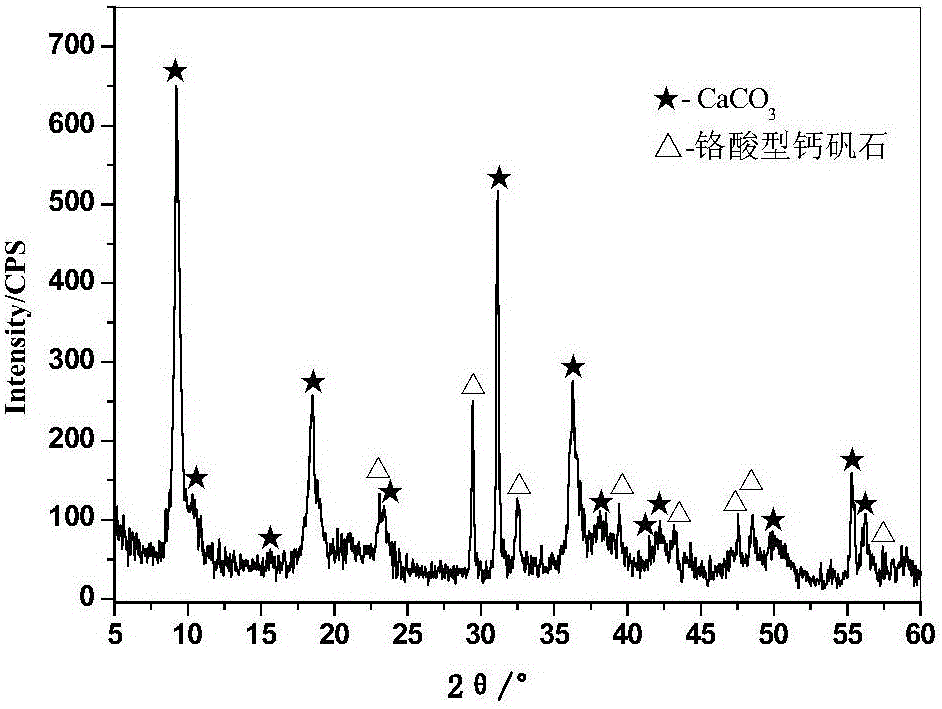

[0032] The XRD pattern of this embodiment gained chromium-containing sediment is as follows figure 1 shown. It can be seen from the figure that the main phase of the sediment obt...

Embodiment 2

[0034] Take the concentration of hexavalent chromium as 300mg·L -1 1000mL of waste water, add 1.28gCa(OH) 2 and 1.39gAlCl 3 ·6H 2 O(Ca(OH) 2 and AlCl 3 ·6H 2 The molar ratio of O is 3:1, and the total mass is 1.5 times the stoichiometric amount required to generate chromate-type ettringite), the pH value of the solution is adjusted to 12.80 using NaOH, and then the reaction is stirred at 20°C for 4h, followed by vacuum The water pump is filtered to obtain chromium-containing sediment and clear liquid. Take the clear liquid to detect the concentration of hexavalent chromium, and the concentration is 80.13mg L -1 , the method reduces the concentration of hexavalent chromium in wastewater by 73.29% in a short period of time, realizes the pretreatment of chromium-containing wastewater well, and reduces the treatment cost.

Embodiment 3

[0036] Take the concentration of hexavalent chromium as 300mg·L -1 1000mL of waste water, add 1.28gCa(OH) 2 and 1.39gAlCl 3 ·6H 2 O(Ca(OH) 2 and AlCl 3 ·6H 2 The molar ratio of O is 3:1, and the total mass is 1.5 times the stoichiometric amount required to generate chromate-type ettringite), the pH value of the solution is adjusted to 12.80 using NaOH, and then the reaction is stirred at 20°C for 24h, followed by vacuum The water pump is filtered to obtain chromium-containing sediment and clear liquid. Take the clear liquid to detect the concentration of hexavalent chromium, and the concentration is 55.26mg L -1 , this method reduces the concentration of hexavalent chromium in wastewater by 81.58% in a short period of time, indicating that prolonging the reaction time is conducive to improving the removal rate of hexavalent chromium in wastewater, but it will reduce the efficiency of wastewater treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com