Synthesis method of glufosinate-ammonium intermediate methylphosphorus dichloride

A technology for the synthesis of methyl phosphorus dichloride and the synthesis method, which is applied in the field of synthesis of glufosinate-ammonium intermediate methyl phosphorus dichloride, can solve the problems of increasing solvent and raw material recovery costs, consuming large solvents, etc., and achieve reduction of recovery Difficulty, the effect of improving product purity and avoiding the use of solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

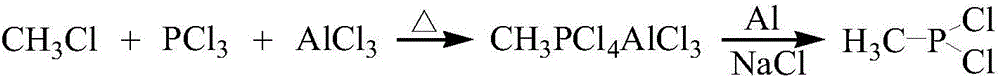

Method used

Image

Examples

Embodiment 1

[0012] Example 1: Add aluminum trichloride and phosphorus trichloride in a closed reactor according to the molar ratio of 1:3, vacuumize to remove the air, stir evenly and then feed in methyl chloride, the molar amount of methyl chloride is aluminum trichloride 2 times, the material is heated to 85 ° C, and then inert nitrogen is passed through to pressurize to 1.5 MPa. The reaction was stopped after 8 hours, the temperature was raised to 100-120°C to remove excess phosphorus trichloride, and the solid was fully dried.

[0013] After heating the ternary complex to a temperature of 140-150° C., adding aluminum powder and sodium chloride, distilling while reacting to obtain methyl phosphorus dichloride, the purity is 99.0%, and the yield is 85.0%.

Embodiment 2

[0014] Example 2: Add aluminum trichloride and phosphorus trichloride in a closed reactor according to the molar ratio of 1:2, vacuumize to remove the air, stir evenly and then feed in methyl chloride, the molar amount of methyl chloride is aluminum trichloride 2 times, the material is heated to 85 ° C, and then inert nitrogen is passed through to pressurize to 1.5 MPa. The reaction was stopped after 8 hours, the temperature was raised to 100-120°C to remove excess phosphorus trichloride, and the solid was fully dried.

[0015] After the ternary complex is heated to a temperature of 140-150°C, aluminum powder and sodium chloride are added, and distilled while reacting to obtain methyl phosphorus dichloride with a purity of 98.5% and a yield of 69.6%.

Embodiment 3

[0016] Example 3: Add aluminum trichloride and phosphorus trichloride in a closed reactor according to the molar ratio of 1:5, vacuumize to remove the air, stir evenly and then feed in methyl chloride, the molar amount of methyl chloride is aluminum trichloride 2 times, the material is heated to 85 ° C, and then inert nitrogen is passed through to pressurize to 1.5 MPa. The reaction was stopped after 8 hours, the temperature was raised to 100-120°C to remove excess phosphorus trichloride, and the solid was fully dried.

[0017] After the ternary complex is heated to a temperature of 140-150°C, aluminum powder and sodium chloride are added, and distilled while reacting to obtain methyl phosphorus dichloride with a purity of 99.4% and a yield of 83.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com