Preparation method of high-purity natural curcumin product

A curcumin and natural technology, applied in the field of high-purity natural pigment curcumin products and preparation thereof, can solve the problems of high cost, long time, large consumption of organic solvents, etc., and achieve the effects of avoiding degradation, short time and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

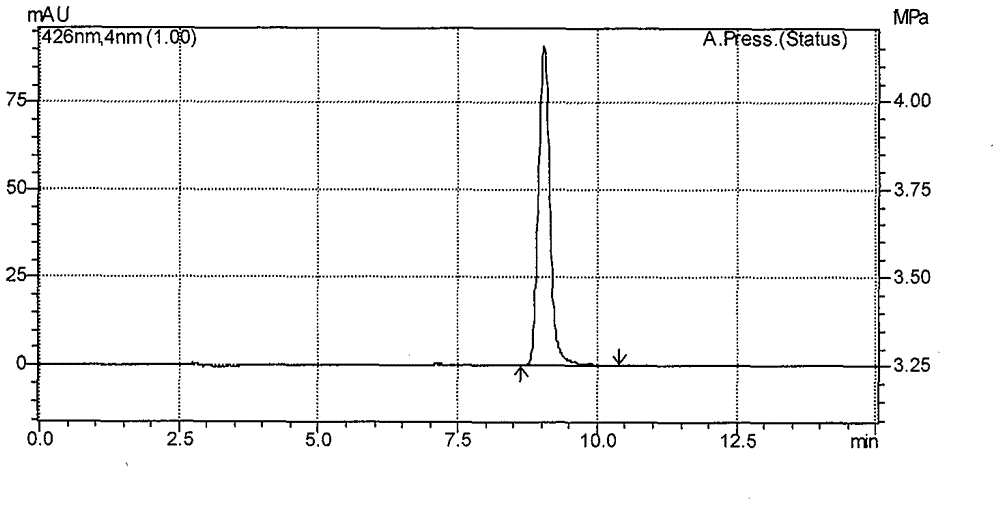

Embodiment 1

[0016] Turmeric rhizome dry powder 100g, 1,2-propanediol / alanine natural deep eutectic solvent 1kg, mix evenly, put it into an ultrasonic container, control the temperature of the material liquid at 15°C, 75W ultrasonic treatment for 1 hour, and then add 5.5kg to add deionized Add water to the extraction mixture, place it at 4°C for 2 hours, remove the supernatant after centrifugation at 5000rpm, and dry the precipitate in vacuum to obtain 0.2g of curcumin product with a purity of 98.5%

Embodiment 2

[0018] Turmeric rhizome dry powder 100g, 1,2-propanediol / alanine natural deep eutectic solvent 1.5kg, mix evenly, put it into an ultrasonic container, control the temperature of the material liquid at 20°C, 75W ultrasonic treatment for 1.5h, then add 12kg to add Add ionized water to the extraction mixture, place it at 4°C for 2 hours, remove the supernatant after centrifugation at 5000rpm, and dry the precipitate in vacuum to obtain 0.28g of curcumin product with a purity of 99.3%

Embodiment 3

[0020] Turmeric rhizome dry powder 100g, 1,2-propanediol / alanine natural deep eutectic solvent 2kg, mix evenly, put it into an ultrasonic container, control the temperature of the material liquid at 25°C, 75W ultrasonic treatment for 2 hours, then add 21kg of deionized water Put it into the extraction mixture, place it at 4°C for 2 hours, remove the supernatant after centrifuging at 5000 rpm, and dry the precipitate in vacuum to obtain 0.35 g of curcumin product with a purity of 99.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com