High-wear-resistance high-adhesive-force modified epoxy amino baking varnish and preparation method thereof

A technology with strong adhesion and epoxy amino, which is applied in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of unfavorable human health, pollution of the environment, and waste of baking paint, so as to benefit the health of workers and improve paint quality. Effects of film hardness and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below through specific examples, but the examples do not limit the protection scope of the present invention.

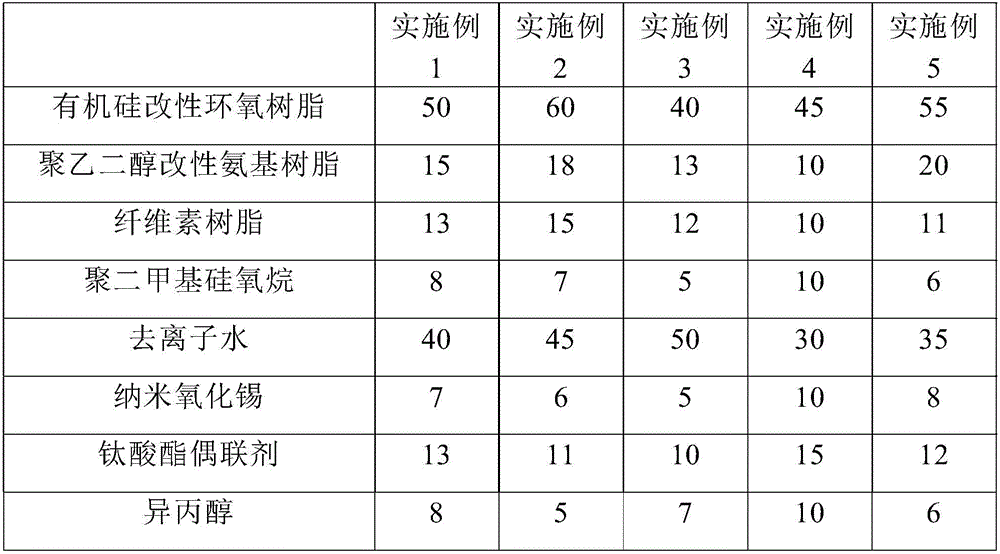

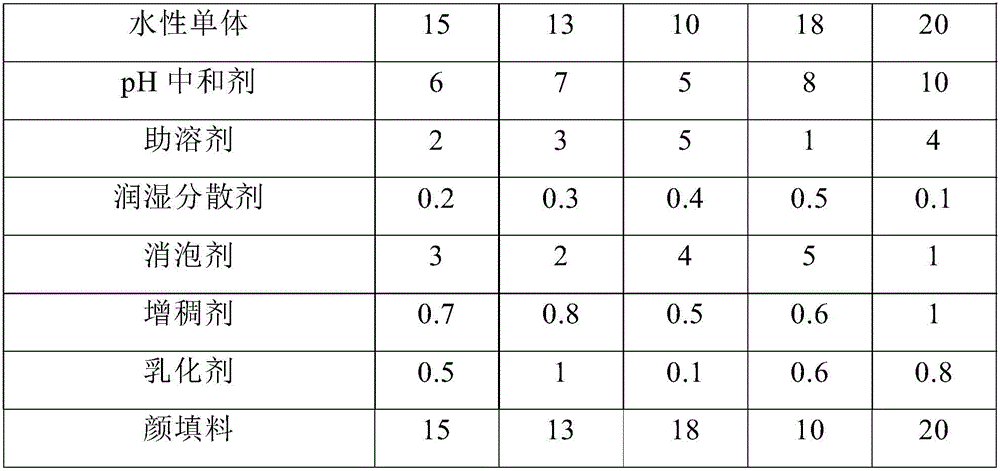

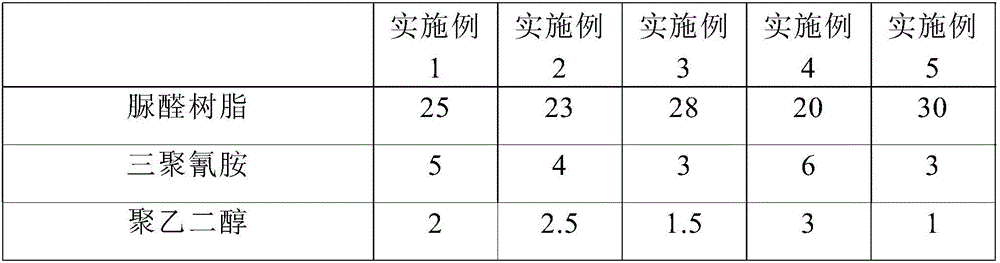

[0033] A modified epoxy amino baking varnish with high wear resistance and strong adhesion provided by the present invention, the baking varnish includes the following components by weight: silicone modified epoxy resin: 40-60 parts, polyethylene glycol modified amino Resin: 10-20 parts, cellulose resin: 10-15 parts, polydimethylsiloxane: 5-10 parts, deionized water: 30-50 parts, nano-tin oxide: 5-10 parts, titanate Coupling agent: 10-15 parts, isopropanol: 5-10 parts, water-based monomer: 10-20 parts, pH neutralizer: 5-10 parts, co-solvent: 1-5 parts, wetting and dispersing agent: 0.1 to 0.5 parts, defoamer: 1 to 5 parts, thickener: 0.5 to 1 part, emulsifier: 0.1 to 1 part, pigment and filler: 10 to 20 parts.

[0034] Further, the baking varnish includes the following components by weight: silicone modified epo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com